Mechanical arm industrial robot for non-standard part spraying and spraying using method of mechanical arm industrial robot

A technology of industrial robots and mechanical arms, applied in the directions of manipulators, spray devices, manufacturing tools, etc., can solve the problems of low spraying efficiency, inconvenient clamping and fixing, etc., and achieve the effect of improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

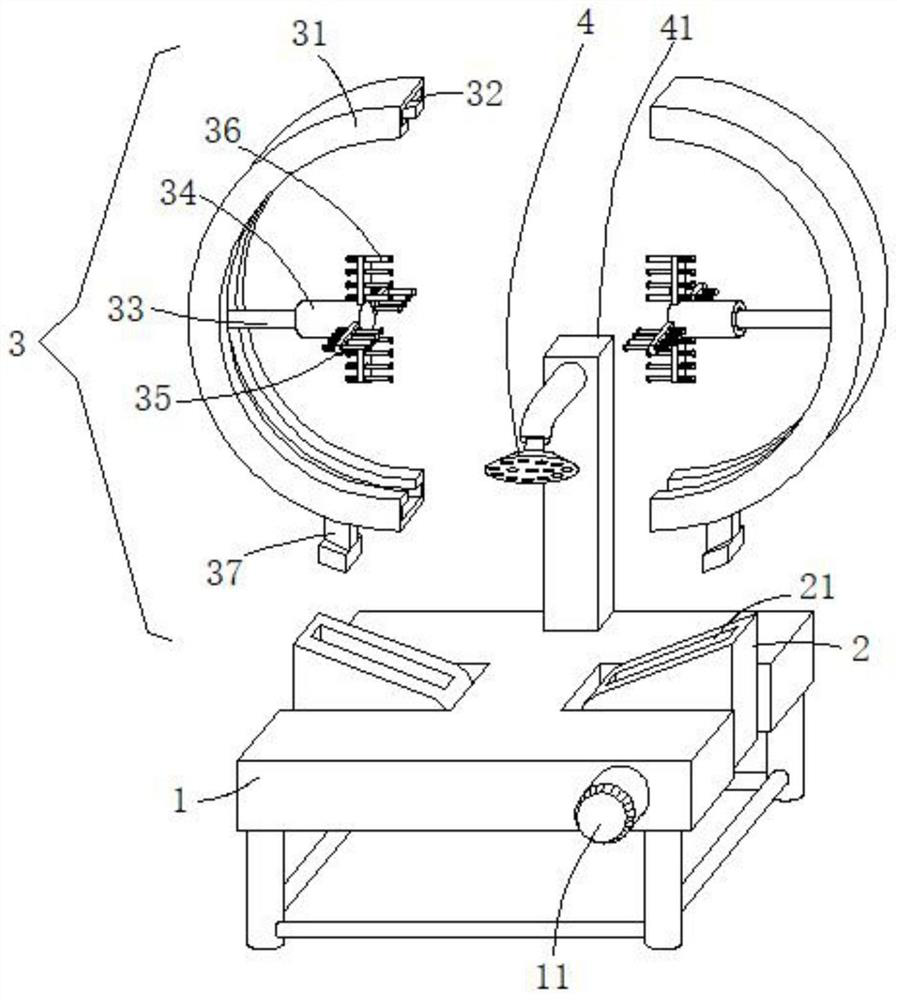

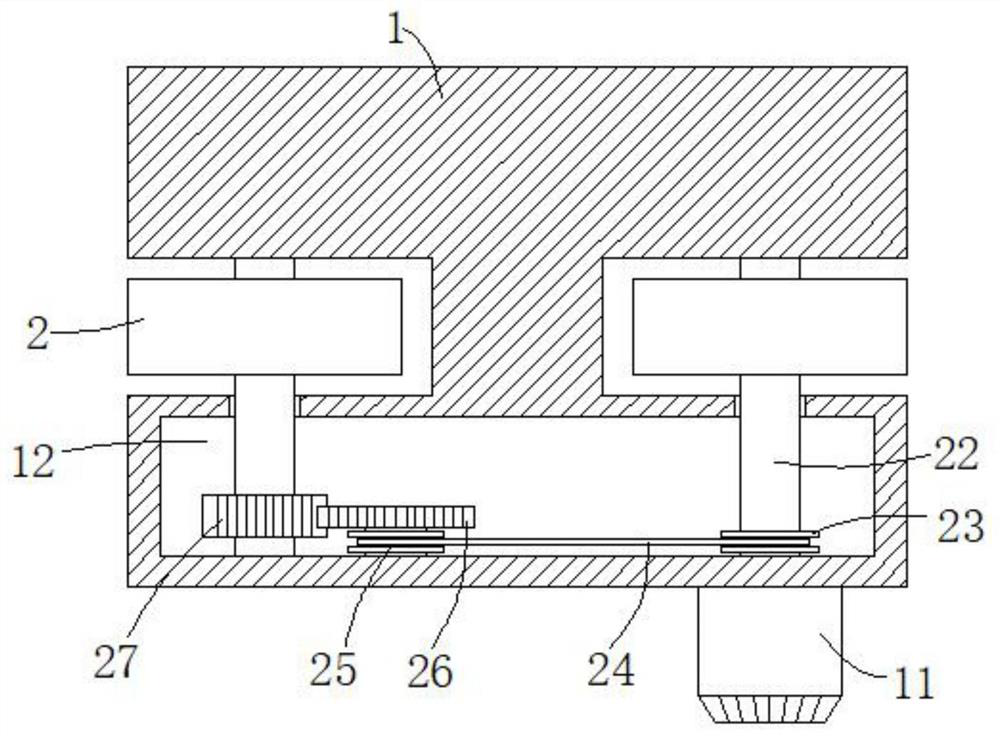

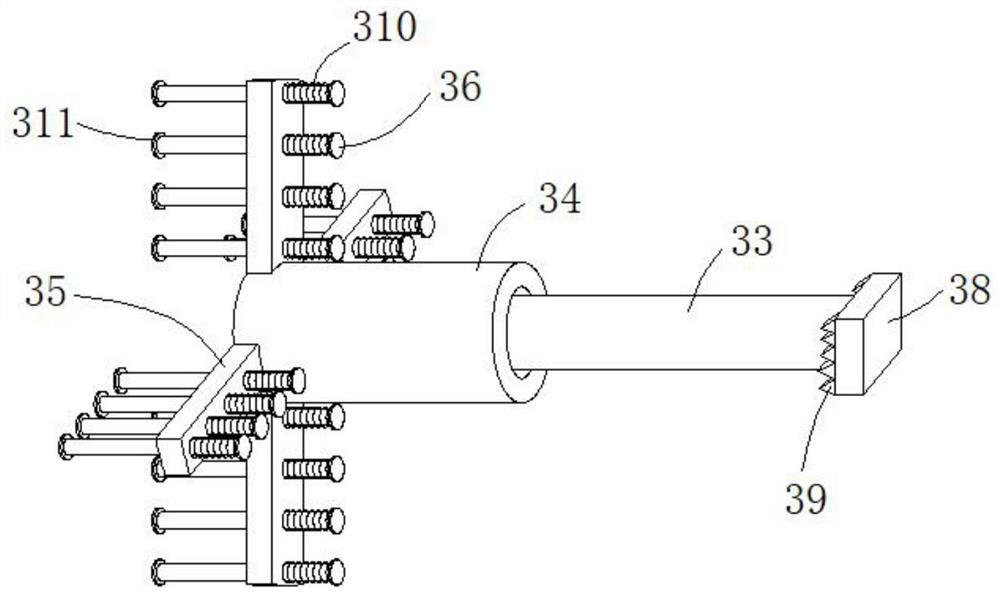

[0031] see Figure 1-4 , the present embodiment provides a mechanical arm industrial robot for spraying non-standard parts and its spraying method, including a support base 1 and a clamping mechanism 3, the bottom corner of the support base 1 is vertically fixed with support legs, and the support base is used to support The legs support the supporting seat 1 in the air, and reinforcing rods are fixed on the opposite side walls of two adjacent supporting legs, and the supporting stability of the supporting legs can be enhanced through the reinforcing rods.

[0032] Both sides of the support base 1 are provided with a hinged notch, and the inside of the hinged notch is rotated by a pin 22 to install a turning block 2, and the turning block 2 can be turned freely in the hinged notch by the pin 22.

[0033] The inside of the support base 1 is provided with an adjustment cavity 12, and the pin shaft 22 of the turning block 2 is rotated and extended to the inside of the adjustment c...

Embodiment 2

[0044] see Figure 1-4 , further improvements have been made on the basis of Example 1:

[0045] The upper end of the overturning block 2 is provided with a 30-45° inclined plane to the side close to the center of the support seat 1, and the inclination angle of the inclined plane is selected within the range of 30-45 °, so that when the semicircular guide support frame 31 passes through the inverted T The sliding block 37 slides along the inverted T-shaped chute 21 of the overturning block 2, and the two semicircular guide support frames 31 can be slid and adjusted to the side close to each other under the natural state by utilizing the inclination angle of the inclined surface, which is convenient Non-standard parts are clamped, and the position of the semicircular guide support frame 31 is adjusted without an additional setting adjustment mechanism.

[0046] The upper and lower sidewalls of the inverted T-shaped slide block 37 are parallel to the slope of the overturning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com