Energy-saving and efficient wheel washing machine capable of recycling sewage and using method thereof

A sewage recycling and wheel washing technology, which is applied in separation methods, vehicle cleaning, chemical instruments and methods, etc., can solve the problems of unsatisfactory vehicle wheel cleaning effect, large water consumption of wheel washing machines, high energy consumption and high cost, and saves money. Equipment flushing water consumption, easy cleaning and maintenance, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

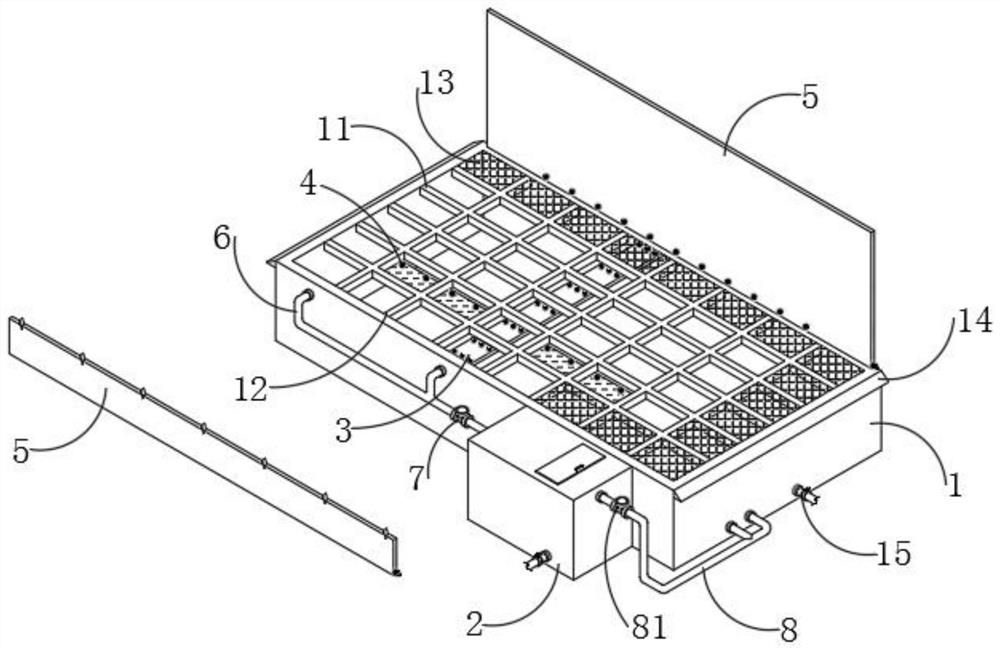

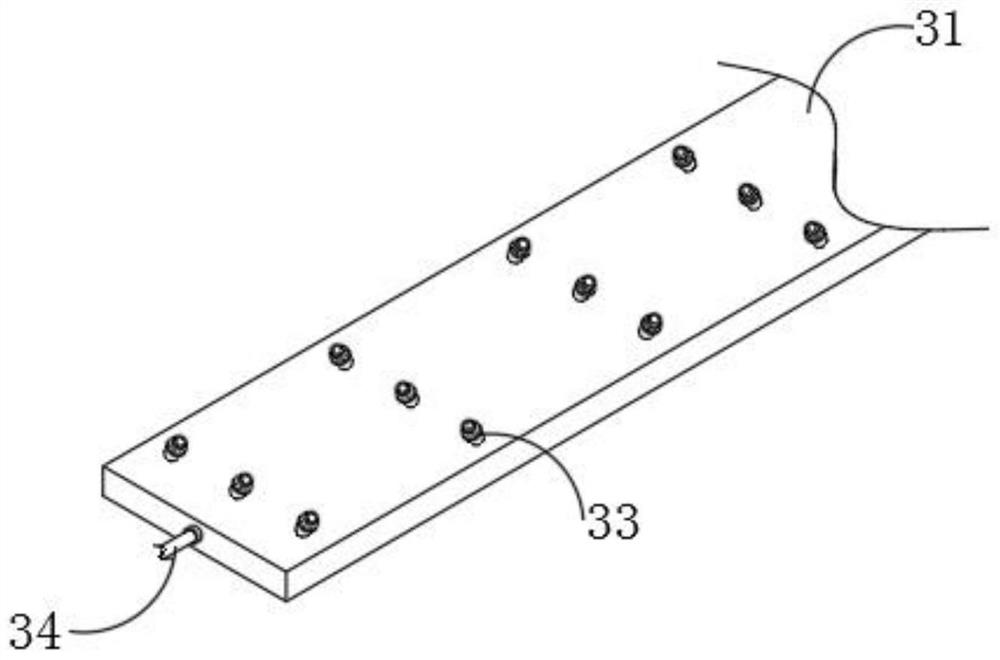

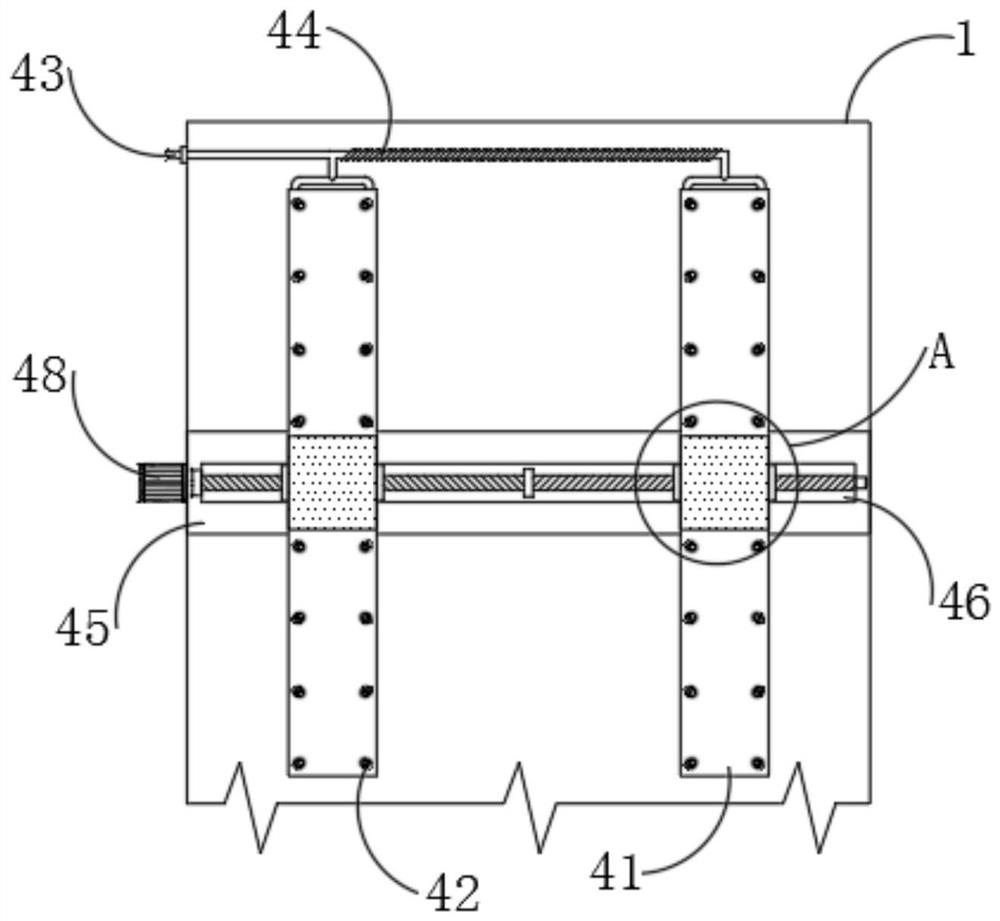

[0032] Such as Figure 1-Figure 6As shown, the energy-saving and high-efficiency wheel washing machine for sewage recycling in this embodiment includes a wheel washing tank body 1, a support mechanism is provided on the top of the wheel washing tank body 1, a circulating water tank 2 is provided on one side of the wheel washing tank body 1, and a wheel washing tank body 1 is provided with a circulating water tank 2. The tank body 1 is provided with a cleaning rack, and the cleaning rack includes a No. 1 cleaning rack 3, a No. 2 cleaning rack 4 and a No. 3 cleaning rack 5. The washing wheel tank body 1 below the supporting mechanism is provided with a No. 1 cleaning rack 3, and the No. 1 cleaning rack The washing wheel sink body 1 below the rack 3 is provided with a No. 2 cleaning rack 4, and the No. 1 cleaning rack 3 and the No. 2 cleaning rack 4 are arranged in a cross-shaped structure. The cleaning rack 5, the water outlet end of the circulating water tank 2 is connected wit...

Embodiment 2

[0042] The structure of the energy-saving and high-efficiency wheel washing machine for sewage recycling in this embodiment is basically the same as that of the energy-saving and high-efficiency washing machine for sewage recycling in Embodiment 1. The difference is that the circulating water tank 2 includes an operation port 21, a U-shaped frame 22, a filter Plate 23 and cover plate 24 (see Figure 7 ). The top of the circulating water tank 2 is provided with an operating port 21, and the operating port 21 is hinged with a cover plate 24. The opposite sides of the circulating water tank 2 below the operating port 21 are provided with U-shaped frames 22. Two U-shaped The frame 22 is provided with a filter plate 23, the lower end of one side of the circulating water tank 2 is provided with a sewage outlet 25, and the sewage outlet 25 is provided with a valve to realize the recycling of washing water of the washing machine, energy saving and environmental protection, and the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com