Electrolytic manganese cathode plate in-out tank lifting appliance and using method

A technology of cathode plates and access slots, applied to load hanging components, cranes, traveling bridge cranes, etc., can solve the problems of low production efficiency and high energy consumption of equipment, achieve good balance, reduce labor intensity, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

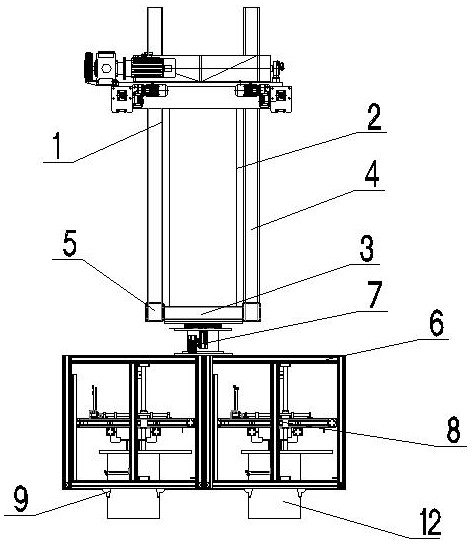

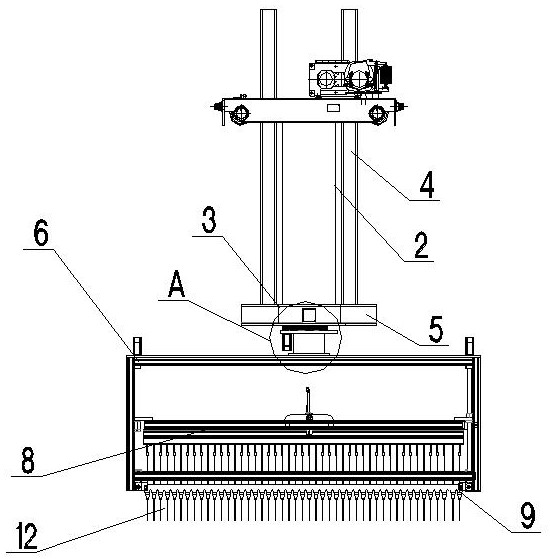

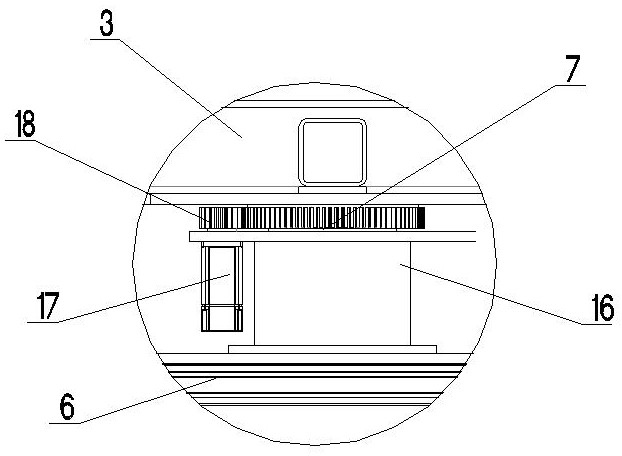

[0022] like figure 1 and figure 2 As shown, the present invention includes the access trough spreader body 1 arranged below the crane, the top of the access trough spreader body 1 is connected with the hoisting mechanism of the crane through the hoisting wire rope 2, and the crane connected with the access trough spreader body 1 is the present technology, and is not the main innovation of the present invention, so the specific structure will not be repeated. The access trough spreader body 1 includes a support frame 3 fixed on the lower part of the hoisting wire rope 2, and the lower part of the hoisting trolley of the crane is fixedly connected with two symmetrically arranged guide columns 4, the guide columns 4 are arranged vertically downward, and the support frame 3 Both ends are fixedly connected with symmetrically arranged guide sleeves 5 , and the guide sleeves 5 are slidably connected to the outside of the guide column 4 . By arranging the guide column 4 and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com