Solvent-resistant mud yellow hole filling ash and preparation method thereof

A solvent and solvent resistance technology, applied in the direction of filling slurry, etc., can solve the problems of drying speed, the number of gray eyes and solvent resistance cannot be unified, and achieve fast drying performance, high coating smoothness, and solvent resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

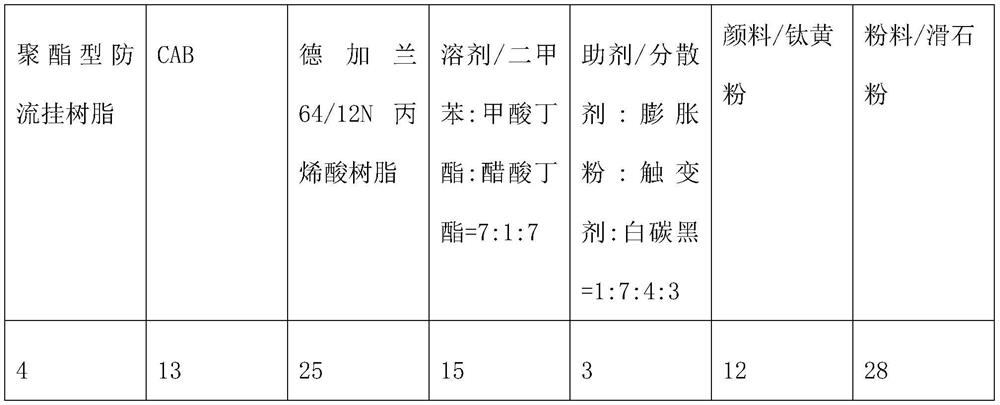

[0020] Embodiment 1 Preparation of solvent-resistant mud yellow putty

[0021] Preparation:

[0022] Polyester type anti-sagging resin YP8818, CAB, Degalan 64 / 12N acrylic resin, and solvent are mixed and dispersed, and additives, pigments and powder are added to continue to disperse. After the dispersion is uniform, grind with a grinder. Can.

[0023] Each composition formula table is as follows table 1:

[0024] Table 1 Recipe table

[0025]

Embodiment 2

[0027] Roughly the same as Example 1, the difference is that the consumption of each substance of the present embodiment is as follows in Table 2:

[0028] Table 2 Formulation table

[0029]

Embodiment 3

[0031] Roughly the same as Example 1, the difference is that the consumption of each substance of the present embodiment is as follows in Table 3:

[0032] Table 3 recipe table

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com