Steel ladle bottom argon blowing automatic butt joint device and using method thereof

A technology of automatic docking and bottom blowing argon, which is used in casting molten material containers, manufacturing tools, metal processing equipment, etc. Reduce the labor intensity of workers, improve the accuracy of automatic docking, the success rate of docking, and the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

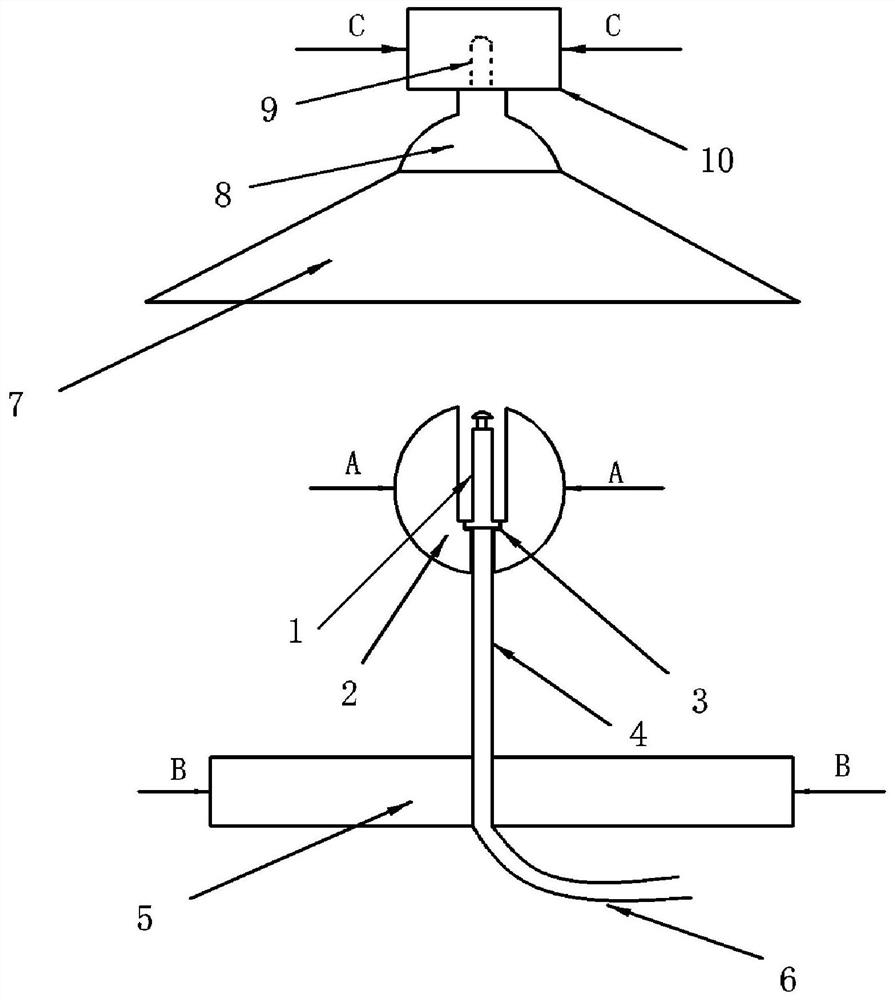

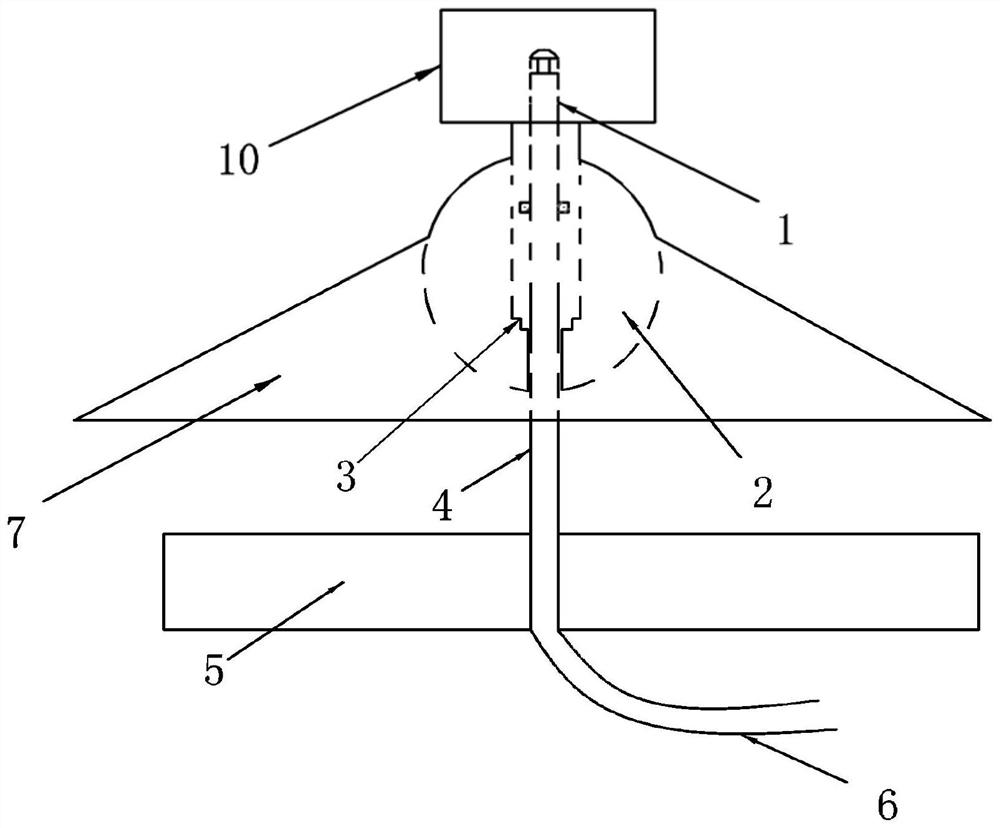

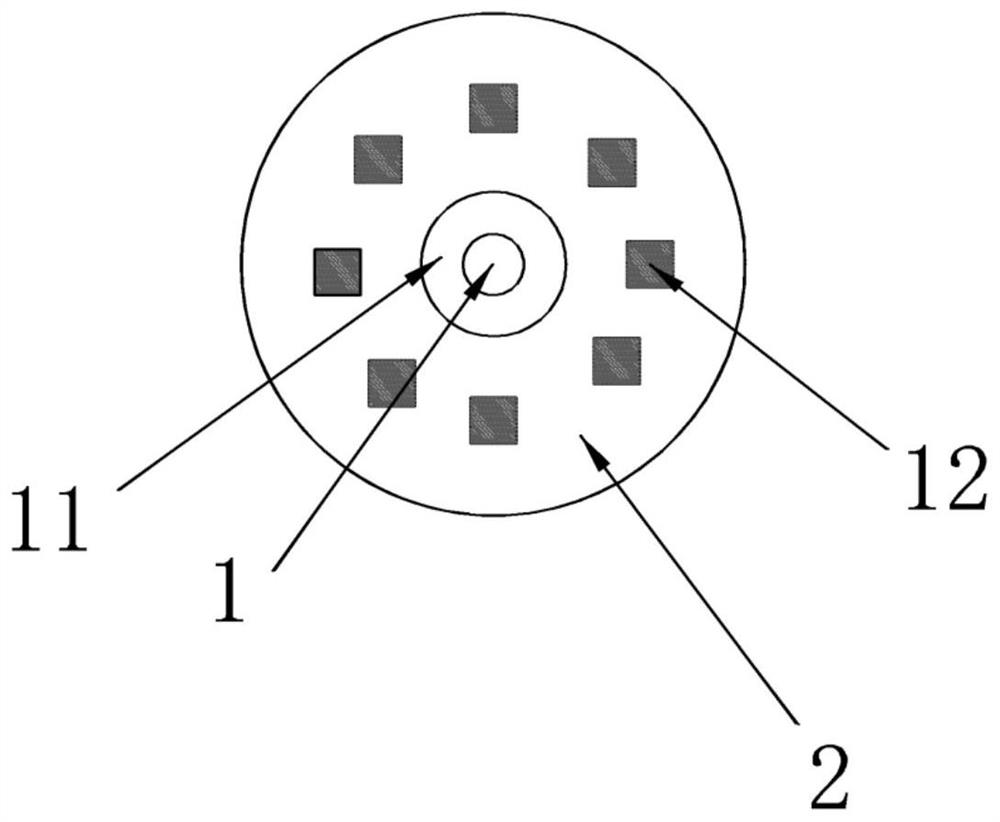

[0039] The present invention provides the following technical solutions: an automatic docking device for argon blowing at the bottom of a ladle includes a transmitter and a receiver, the transmitter includes a positioning head 2 and an external argon blowing device, and the receiver includes a receiving bowl 7 and a ladle The argon interface 10; the external argon blowing device includes an argon tube connector 1, the axis of the argon tube connector 1 coincides with the central axis of the positioning head 2, and the argon tube connector 1 is embedded in the positioning head 2 And it is slidingly connected with the positioning head 2, the inner surface of the receiving bowl top 8 of the receiving bowl 7 is adapted to the spherical surface of the positioning head, and the shape of the inner surface 9 of the argon gas interface of the described argon gas interface 10 is consistent with the shape of the argon gas interface. The shape of the outer surface of the air pipe connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com