Water pump connecting flexible sleeve for building construction

A technology of building construction and casing, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of water seepage and leakage, troublesome replacement, different thermal expansion and contraction coefficients, etc., to improve the sealing effect and prevent leakage The effect of preventing leaks and gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

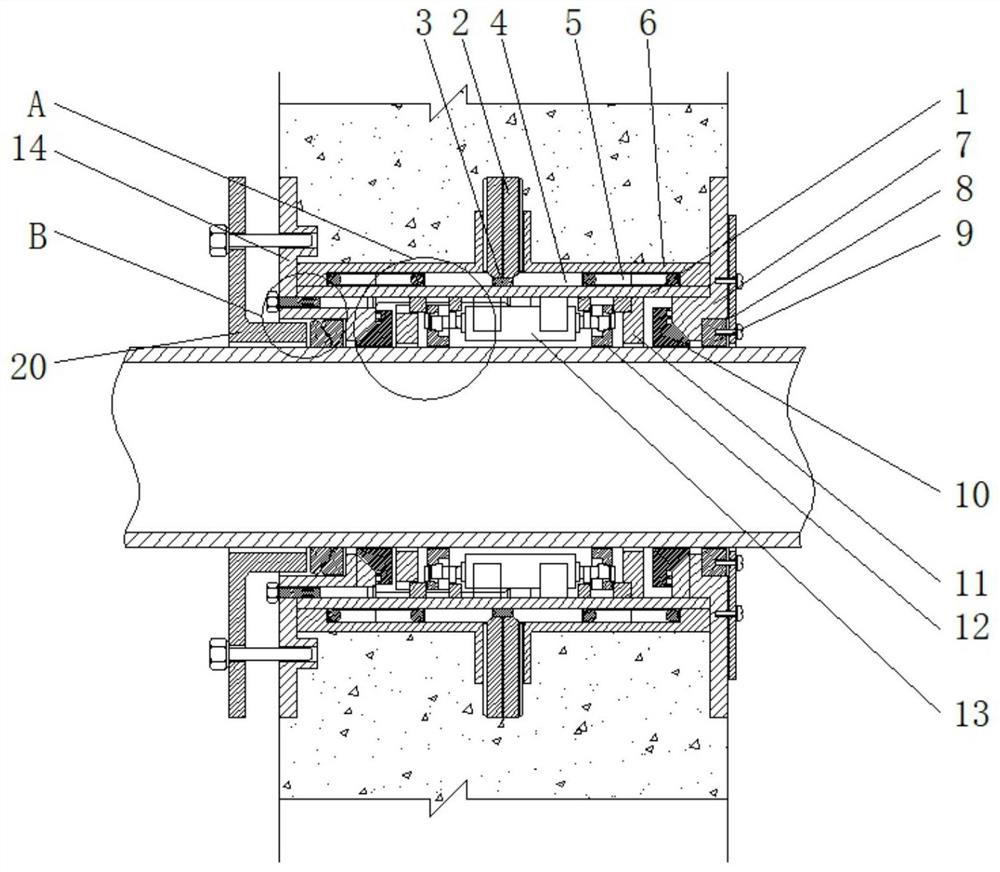

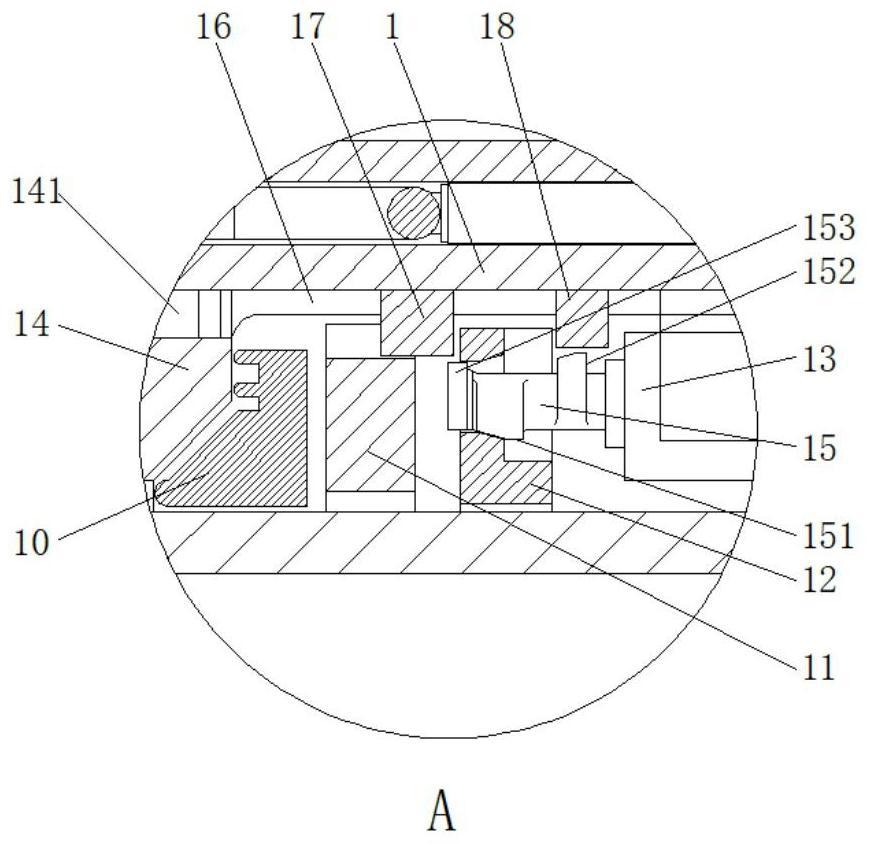

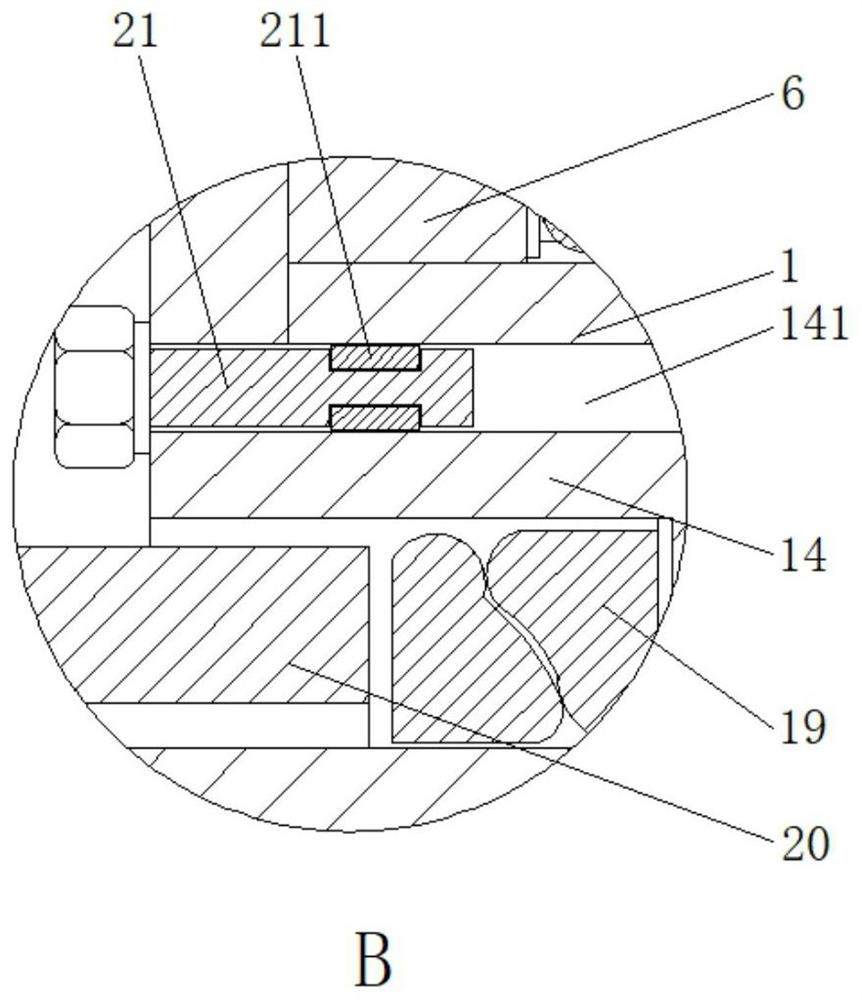

[0056] Such as Figure 1-Figure 15 As shown, a kind of water pump connection flexible casing for building construction includes a main pipe body 1, and the two ends of the main pipe body 1 are respectively provided with a flange flange plate 7 on the water surface and a flange flange plate 14 on the back water surface, and the main pipe body One end of 1 is connected with a flanged gland 20 through an extruded sealing ring 19, the middle of the main body 1 is used for piercing the inner pipe, one end of the inner pipe is connected with the water pump, and the middle of the main body 1 is provided with a telescopic wing ring 2 , the telescopic wing ring 2 is provided with rubber strips 021 at intervals, and a rubber gasket 3 is provided between the inner wall of the telescopic wing ring 2 and the outer wall of the main body 1;

[0057] The inner walls of the flange flange plate 7 on the upstream surface and the flange flange plate 14 on the backwater surface are respectively pr...

Embodiment 2

[0066] Such as Figure 1-Figure 15 As shown, a kind of water pump connection flexible casing for building construction includes a main pipe body 1, and the two ends of the main pipe body 1 are respectively provided with a flange flange plate 7 on the water surface and a flange flange plate 14 on the back water surface, and the main pipe body One end of 1 is connected with a flanged gland 20 through an extruded sealing ring 19, the middle of the main body 1 is used for piercing the inner pipe, one end of the inner pipe is connected with the water pump, and the middle of the main body 1 is provided with a telescopic wing ring 2 , the telescopic wing ring 2 is provided with rubber strips 021 at intervals, and a rubber gasket 3 is provided between the inner wall of the telescopic wing ring 2 and the outer wall of the main body 1;

[0067] The inner walls of the flange flange plate 7 on the upstream surface and the flange flange plate 14 on the backwater surface are respectively pr...

Embodiment 3

[0080] like Figure 1-Figure 15 As shown, a kind of water pump connection flexible casing for building construction includes a main pipe body 1, and the two ends of the main pipe body 1 are respectively provided with a flange flange plate 7 on the water surface and a flange flange plate 14 on the back water surface, and the main pipe body One end of 1 is connected with a flanged gland 20 through an extruded sealing ring 19, the middle of the main body 1 is used for piercing the inner pipe, one end of the inner pipe is connected with the water pump, and the middle of the main body 1 is provided with a telescopic wing ring 2 , the telescopic wing ring 2 is provided with rubber strips 021 at intervals, and a rubber gasket 3 is provided between the inner wall of the telescopic wing ring 2 and the outer wall of the main body 1;

[0081] The inner walls of the flange flange plate 7 on the upstream surface and the flange flange plate 14 on the backwater surface are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com