Method for testing compression amount of positive electrode sealing element of lithium battery

A testing method and technology of sealing parts, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of fragile samples, inaccurate data, destructive samples, etc., achieve accurate measurement results, reduce measurement errors, Effect of reduction in seal compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sample: 32135 lithium battery cover

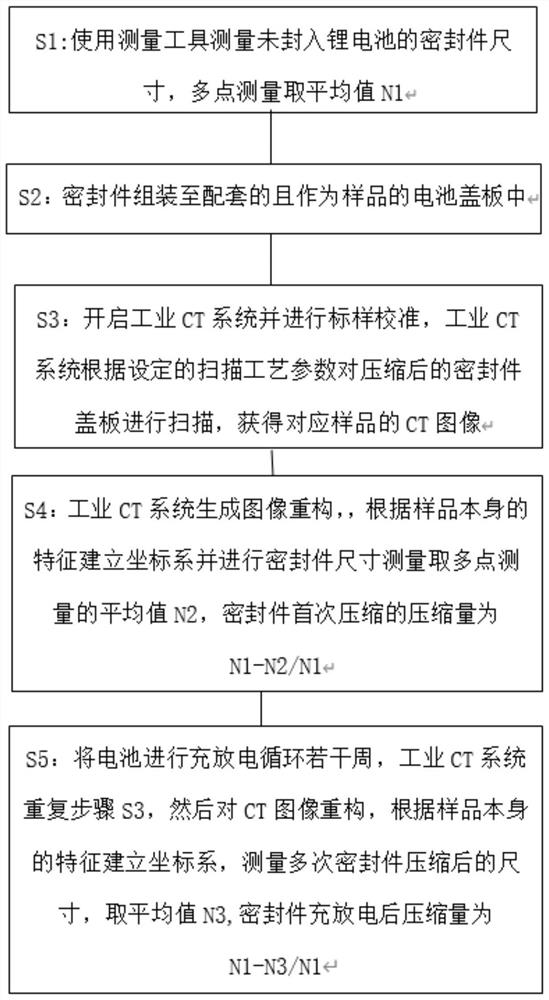

[0035] Such as figure 1 Shown, a kind of test method of the compression of lithium battery positive electrode seal, comprises the following steps:

[0036] S1. Use a screw micrometer to measure the size of the seal 10 times without sealing the cover plate, take the average value N1 of multi-point measurement, and take the average value N1=0.998mm;

[0037] S2, the sealing member is assembled into the supporting battery cover plate as a sample;

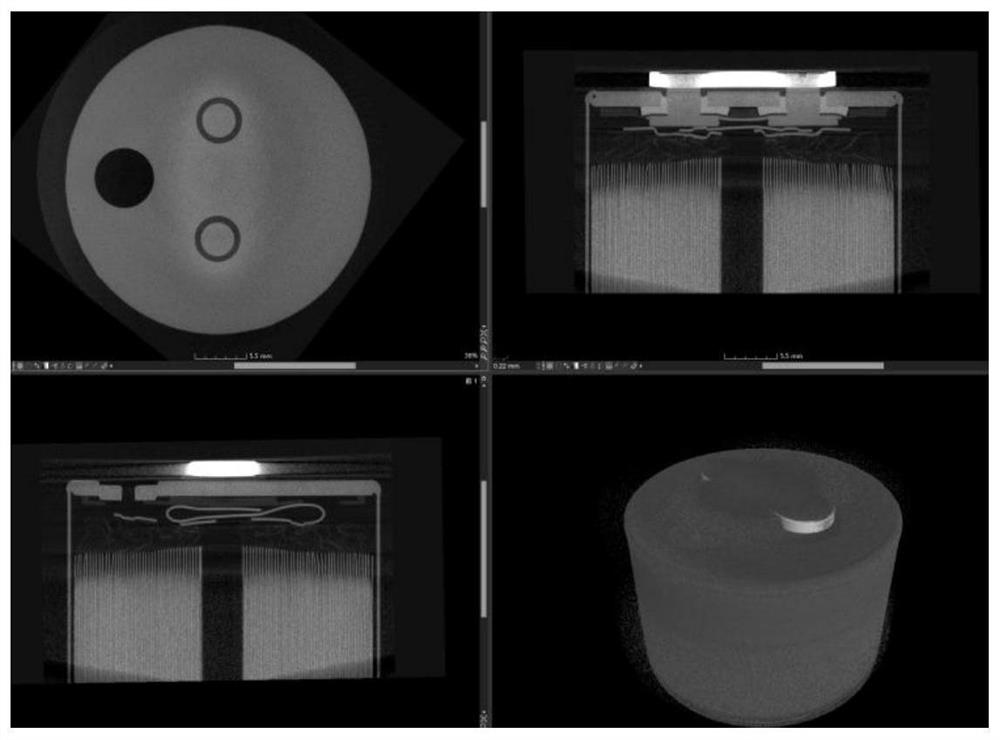

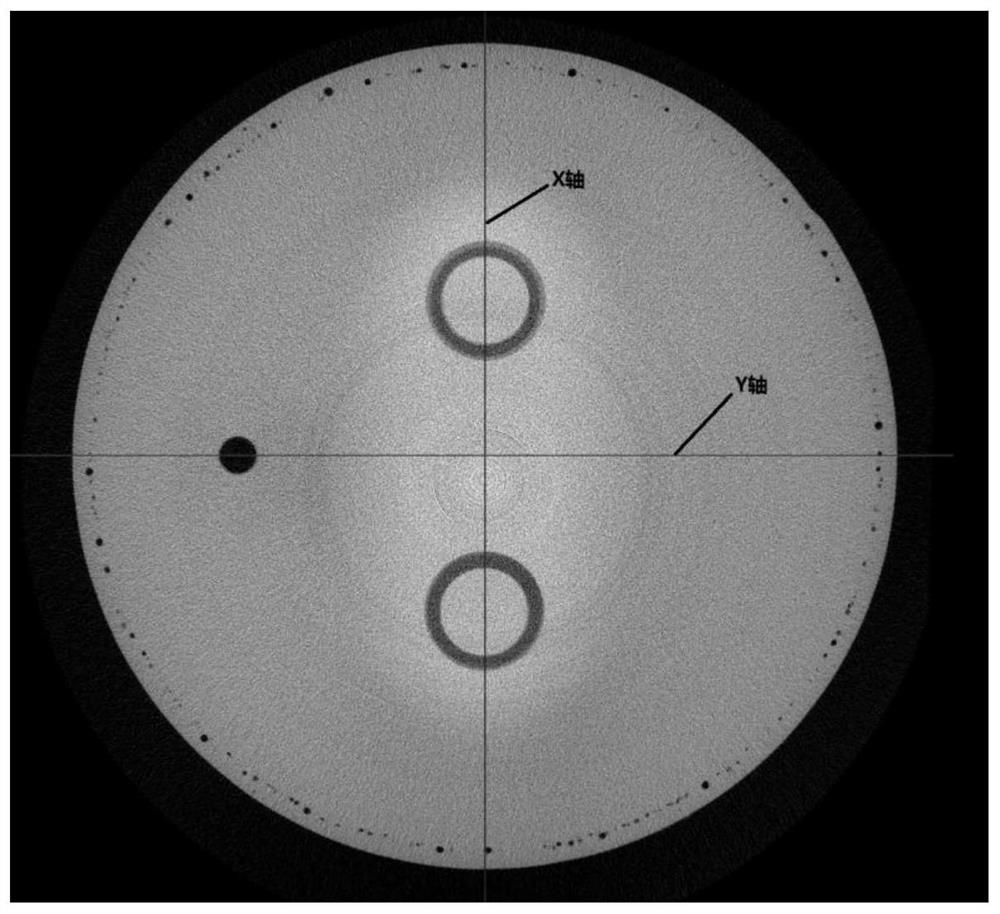

[0038] S3. Turn on the industrial CT system and perform standard sample calibration. The industrial CT system scans the compressed seal cover plate according to the set scanning process parameters to obtain the CT image of the corresponding sample, such as figure 2 shown;

[0039] Turn on the industrial CT system and calibrate the standard sample as follows: use the stylus (ruby diameter 2.5mm) to calibrate the industrial CT detection equipment, and adjust the resolution to 25 μm.

[00...

Embodiment 2

[0048] Sample: standard VDA type battery cover positive electrode

[0049] Such as figure 1 Shown, a kind of test method of the compression of lithium battery positive electrode seal, comprises the following steps:

[0050] S1. Use a screw micrometer to measure the size of the seal 10 times without sealing the cover plate, take the average value N1 of multi-point measurement, and take the average value N1=0.999mm;

[0051] S2, the sealing member is assembled into the supporting battery cover plate as a sample;

[0052]S3. Turn on the industrial CT system and perform standard sample calibration. The industrial CT system scans the compressed seal cover plate according to the set scanning process parameters to obtain the CT image of the corresponding sample, such as figure 2 shown;

[0053] Turn on the industrial CT system and calibrate the standard sample as follows: use the stylus (ruby diameter 2.5mm) to calibrate the industrial CT detection equipment, and adjust the resol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com