Modular functional plug suitable for plug-in type test junction box and use method

A test wiring, plug-in technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of low scalability and freedom, complex operation risks, difficult to adapt to the new situation of electric energy metering operation and maintenance, etc. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

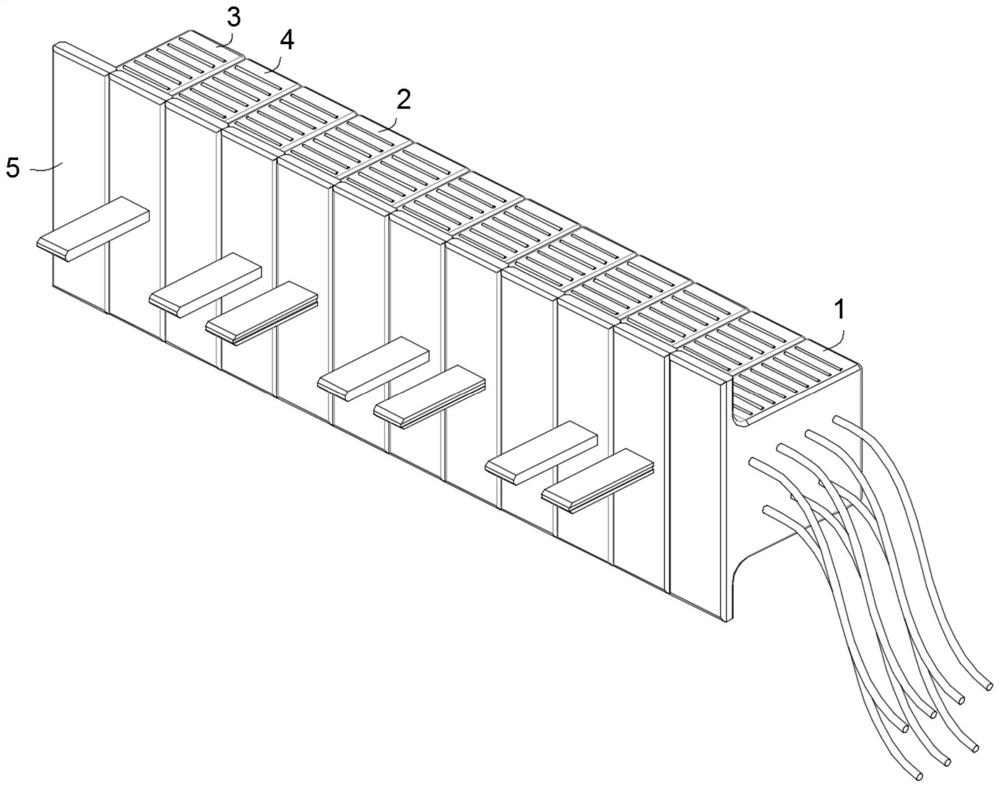

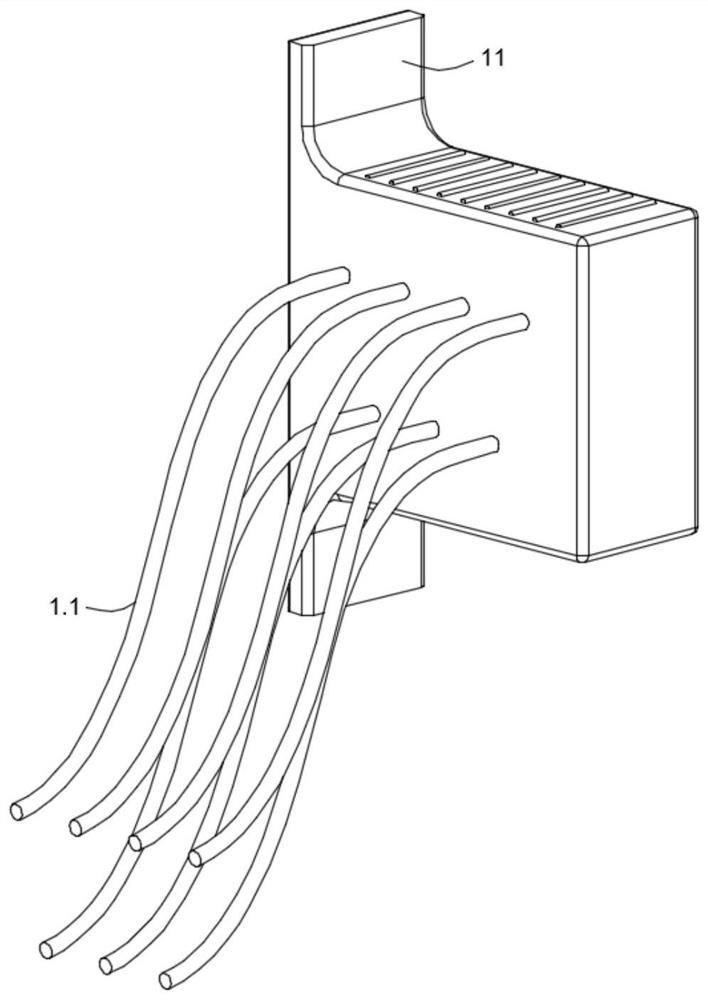

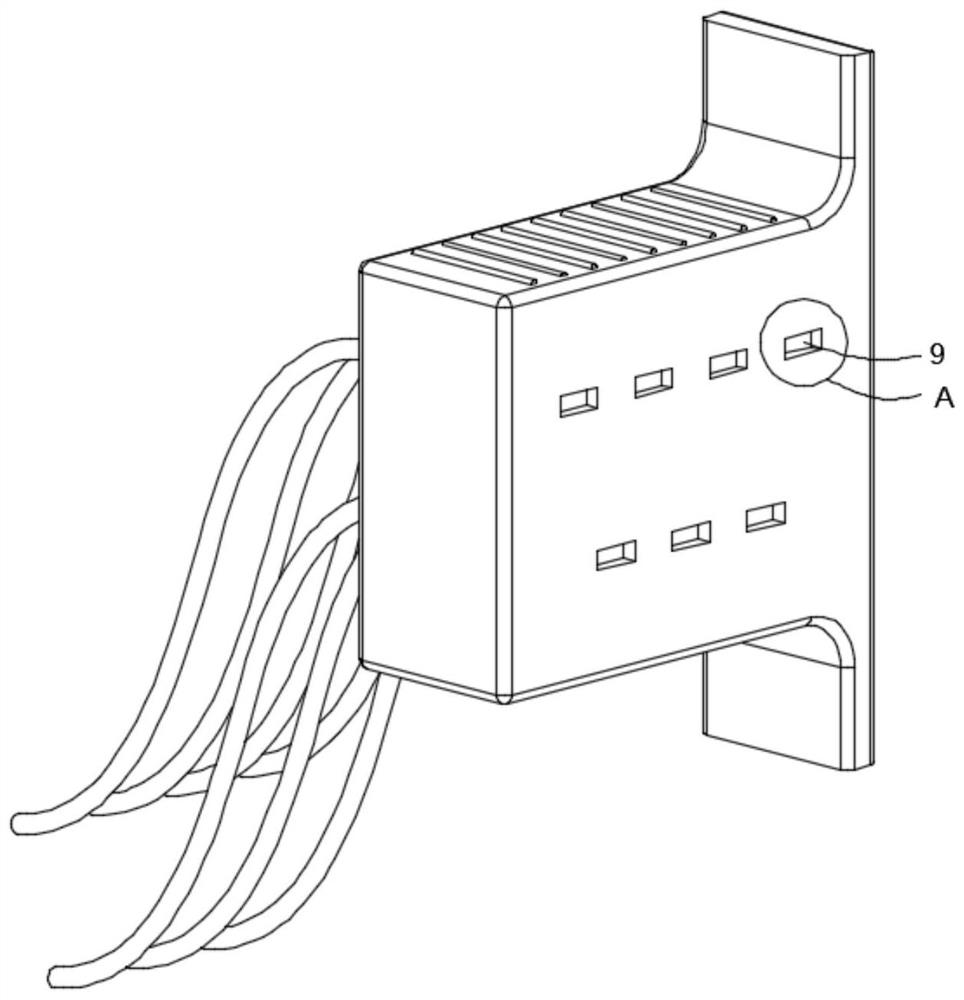

[0053] Such as Figure 1-19 As shown, the modular functional plug suitable for the plug-in test junction box includes a junction module, a closed module, a current module, a voltage module, a partition module and a relay module. The current module, voltage module and partition module are respectively set There are current module connecting plugs, voltage module connecting plugs and partition module connecting plugs matched with the plug-in test junction box. The current module, voltage module, partition module and relay module are all provided with detachable connection with other modules. plugs and sockets, the wiring module is provided with sockets for detachable connection with other modules, the closed module is provided with plugs for detachable connection with other modules, the current module, voltage module, isolation module and The relay modules may not be selected or at least one may be selected according to actual needs and arranged in order according to actual need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com