Real-time clearing device for carbon black in tire oil refining

A cleaning device, medium carbon black technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of affecting pipeline flow, adhesion, and the inner wall of the pipeline cannot be cleaned in real time, so as to ensure the flow Ingenious effect of area and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

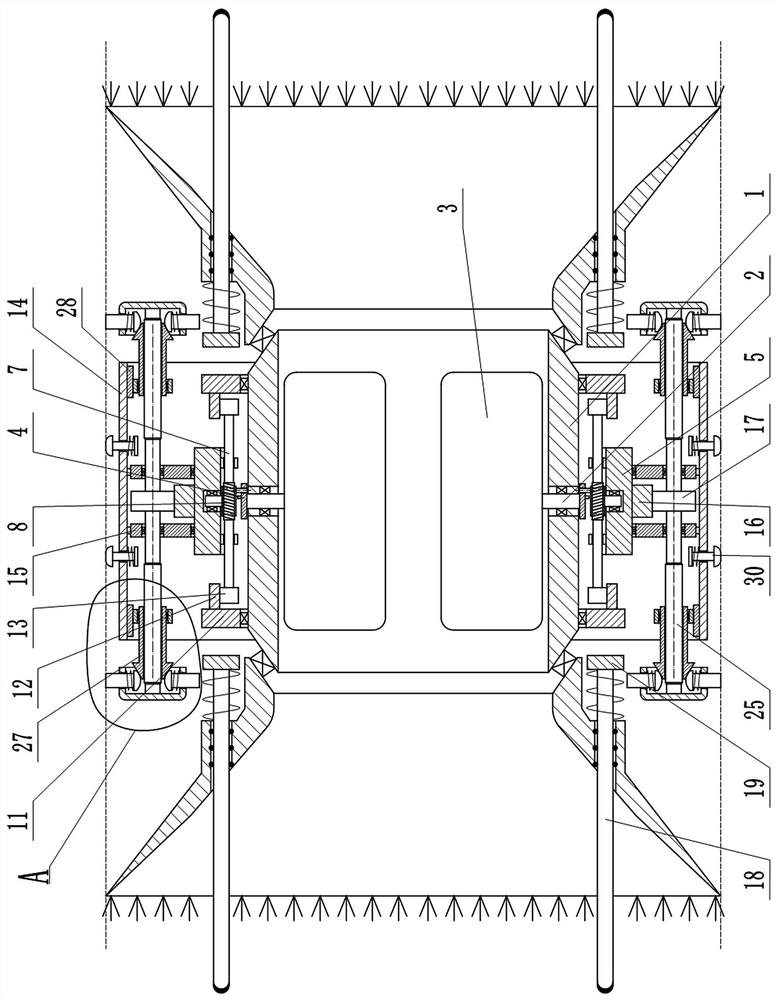

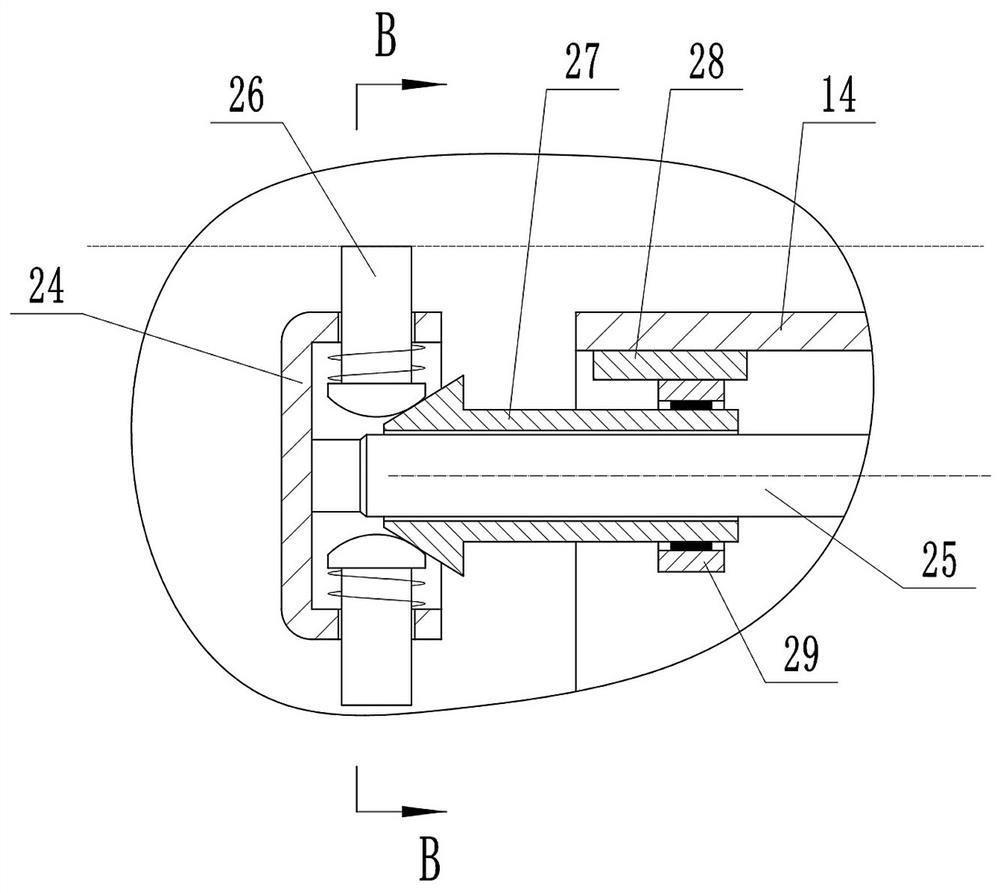

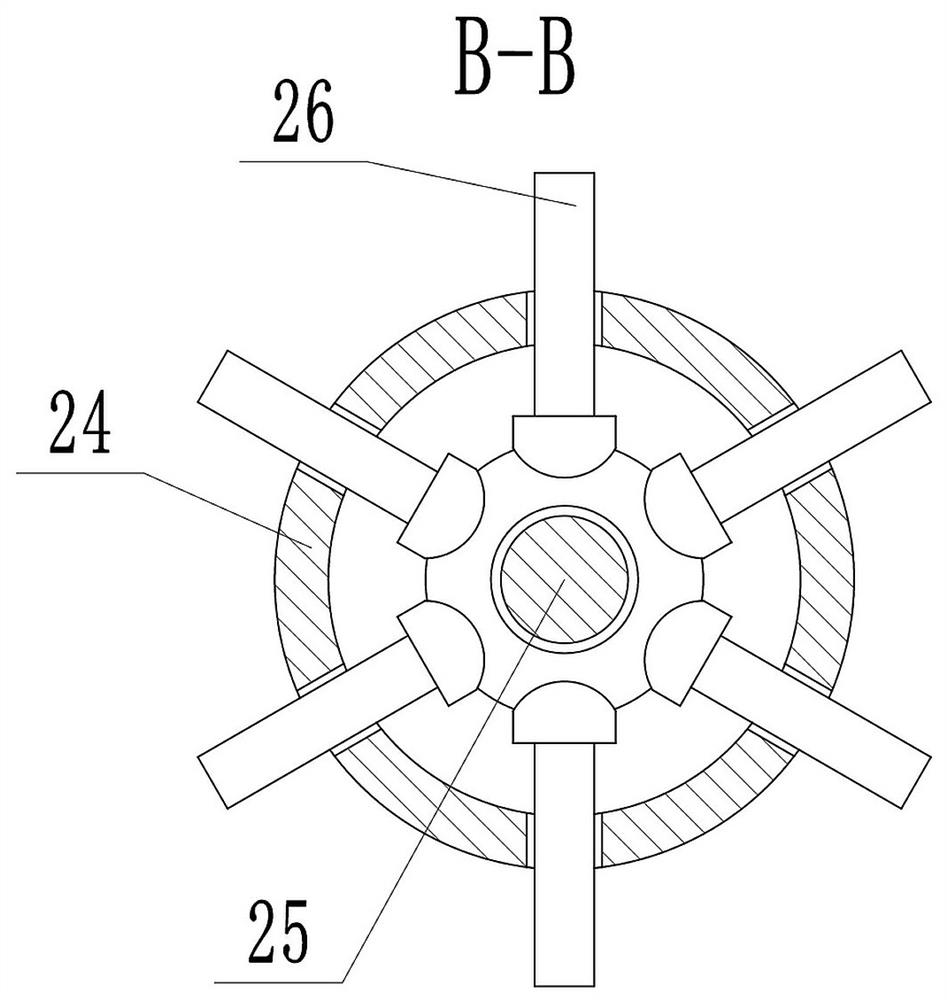

[0020] Conjunction with the drawings make further detailed description of specific embodiments of the present invention.

[0021] Depend on Figure 1 to 8 Are given, the present invention comprises a horizontal hollow cylinder 1, through the side wall with a plurality of rotatable hollow cylindrical shaft 2, a plurality of circumferentially uniform rotary shaft 2, a plurality of flat inner hollow cylinder 3, plate 3 and 2-one correspondence with the fixed shaft, a hollow cylindrical outer side rotation shaft of the turntable 2-one correspondence 4, the turntable 4 is fixed coaxially with the shaft 2, an outer hollow cylinder having an annular cylinder set 5, the annular tube with a hollow cylinder 5 1 between the block 6 is fixed by a plurality of fixing, the turntable 4 is mounted a plurality of one-worm wheel 8 inner annular cylindrical worm gear mechanism 7 5, wherein the worm wheel 8 is hinged at the inside annular cylinder 5, the worm 7 along the axial direction of a hollow cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com