Pipeline cleaning device and method

A pipeline cleaning and pipeline technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as low efficiency and insignificant cleaning effect, and achieve good cleaning effect and pipeline cleaning cycle. The effect of shortening and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

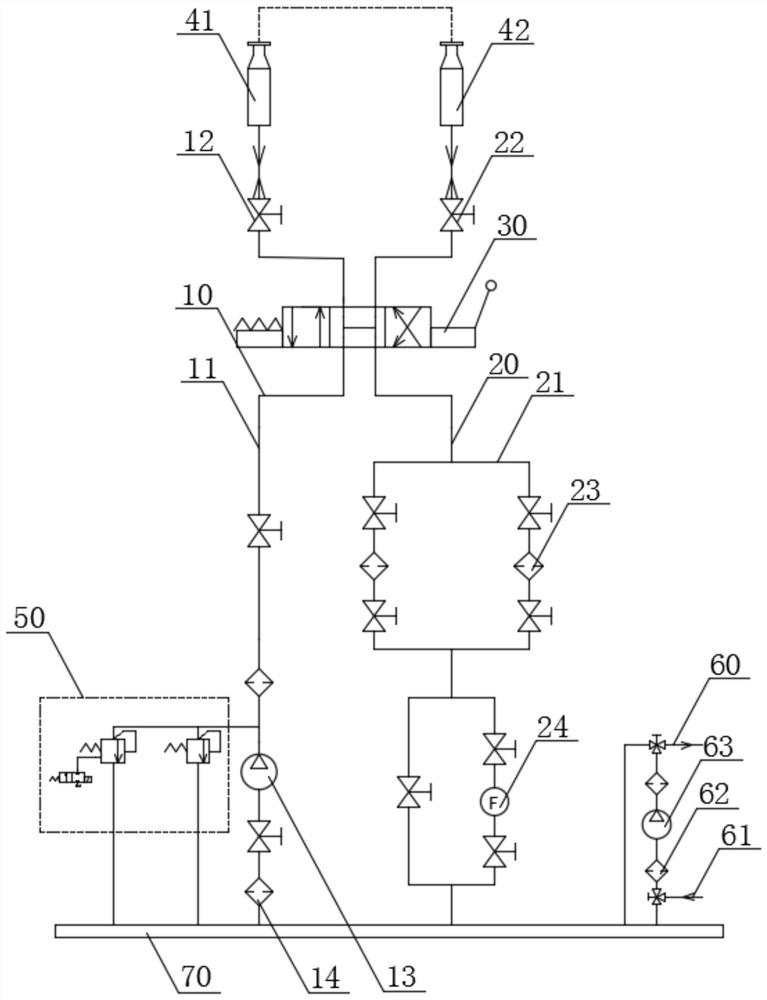

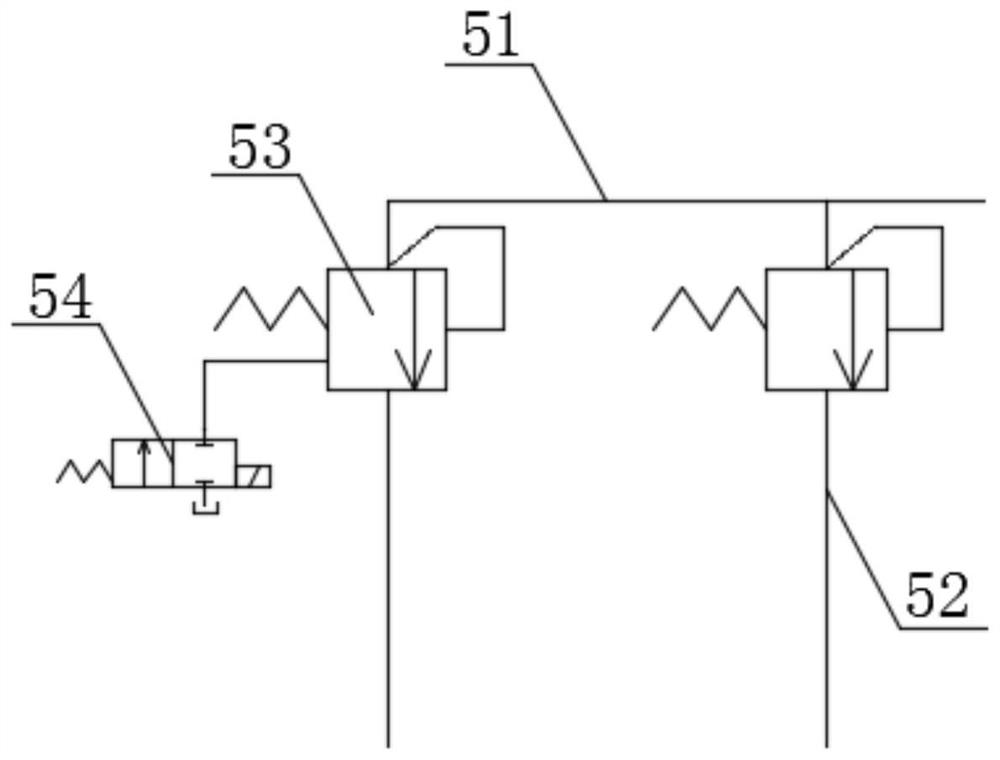

[0042] see Figure 1-3 The present invention provides a technical solution: a pipeline cleaning device, including a first pipeline cleaning component 10 , a second pipeline cleaning component 20 , a reversing device 30 , a pulse component 50 , a refueling component and a liquid flow channel 70 .

[0043] In this embodiment, specifically, the reversing device 30 specifically adopts a three-position four-way manual reversing valve.

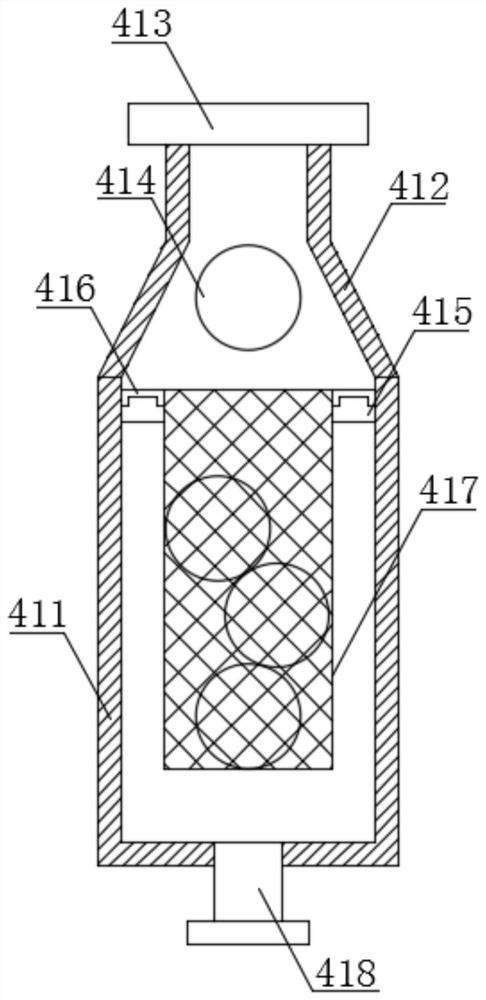

[0044] Wherein, the first pipeline cleaning assembly 10 includes a first cleaning pipeline 11 , and a first high-pressure ball valve 12 , a cleaning screw pump 13 , a switching valve and a first fine filter 14 are arranged outside the first cleaning pipeline 11 .

[0045] In this embodiment, specifically, there are two first fine filters 14 on the first cleaning pipeline 11, one of the on-off valves is set between the liquid inlet pipe 43 and the liquid outlet pipe 44, and the other on-off valve is set Between the cleaning screw pump 13 and the fir...

Embodiment 2

[0070] see Figure 4 , the present invention provides a technical solution: a pipeline cleaning method, comprising the following steps:

[0071] S1. First, connect the two ends of the ship pipeline to be cleaned to the first cleaning connection seat and the second cleaning connection seat respectively, so that the ship pipeline is connected end to end to form a pipeline;

[0072] S2. Then stop the handle of the reversing device in the middle position, and the cleaning oil forms an internal circulation in the equipment, which can complete the starting of the screw pump and the heating of the oil;

[0073] S3, and then rotate the handle of the reversing device 45° clockwise, the cleaning oil enters the outer circulation of the cleaning pipeline from the first cleaning pipeline, and then enters the second cleaning connection seat from the second cleaning pipeline, and then Enter the pipeline of the ship to be cleaned, and the cleaning ball and cleaning oil will clean the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com