Automatic clamping strip mounting device and mounting method thereof

An automatic installation and clip technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that clips cannot meet production and processing needs, and achieve the effect of ensuring smooth installation, high position accuracy, and avoiding splits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

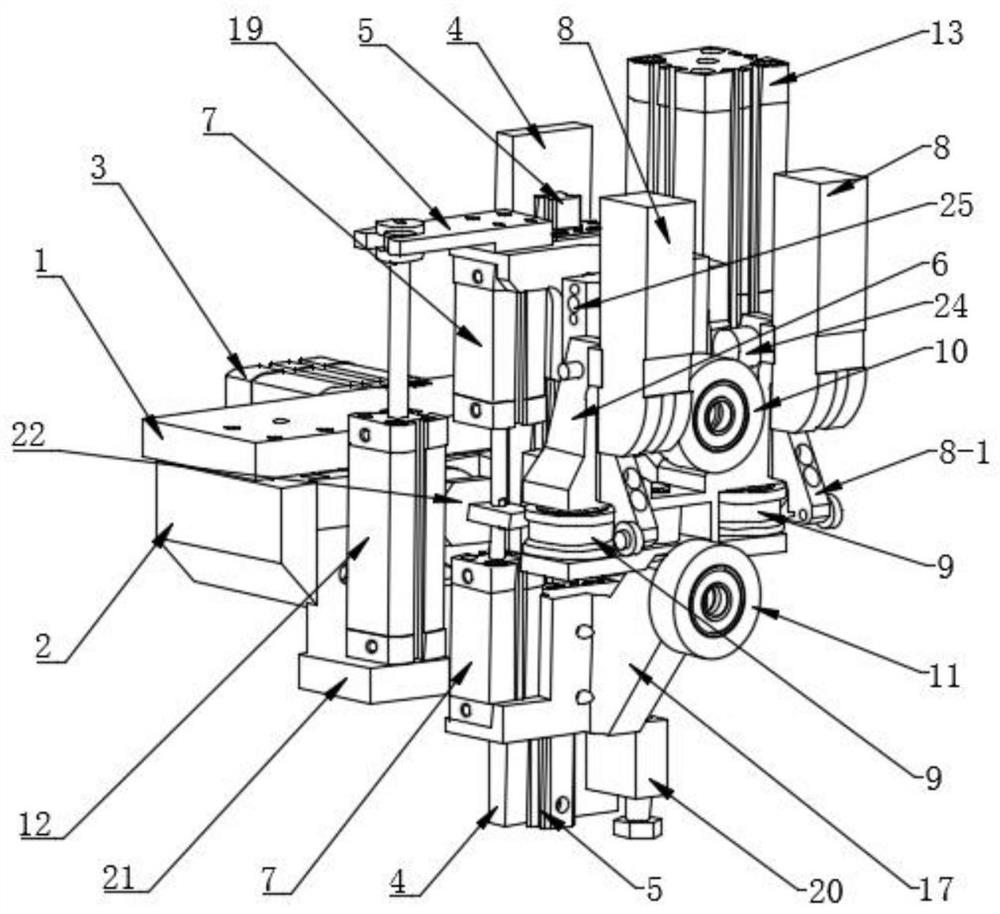

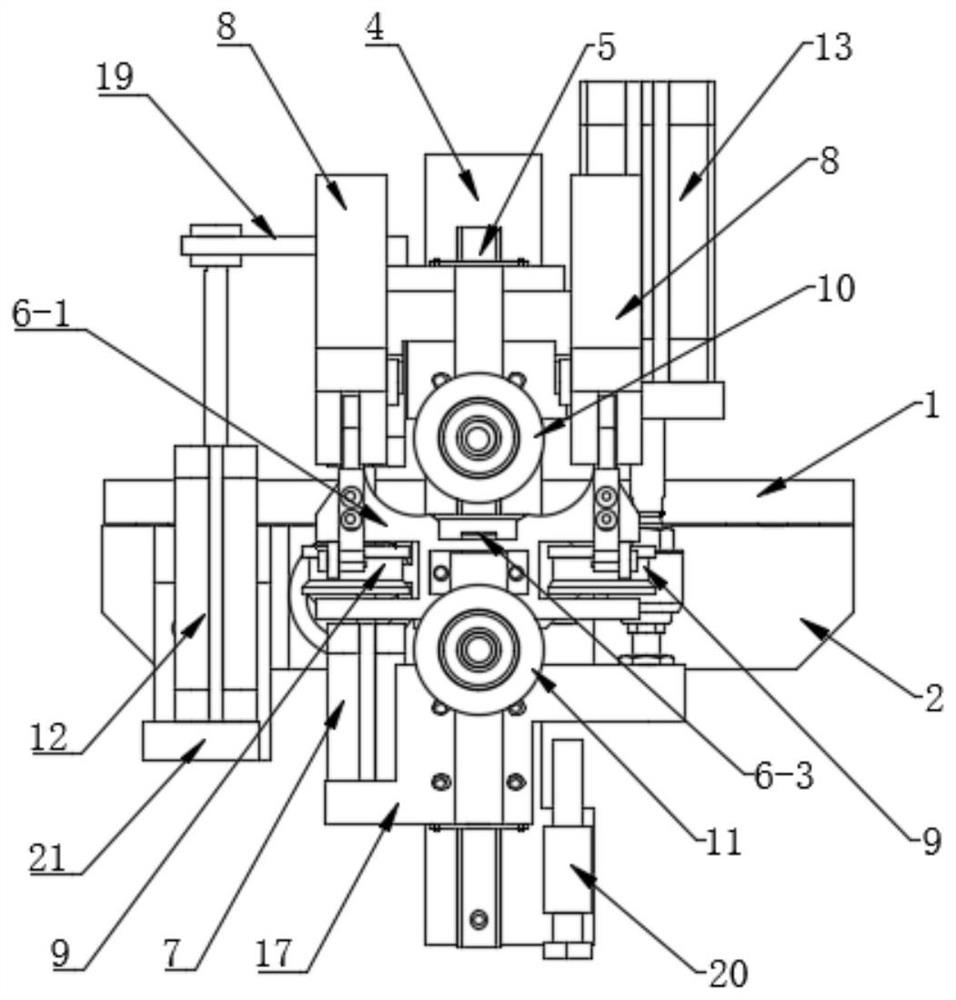

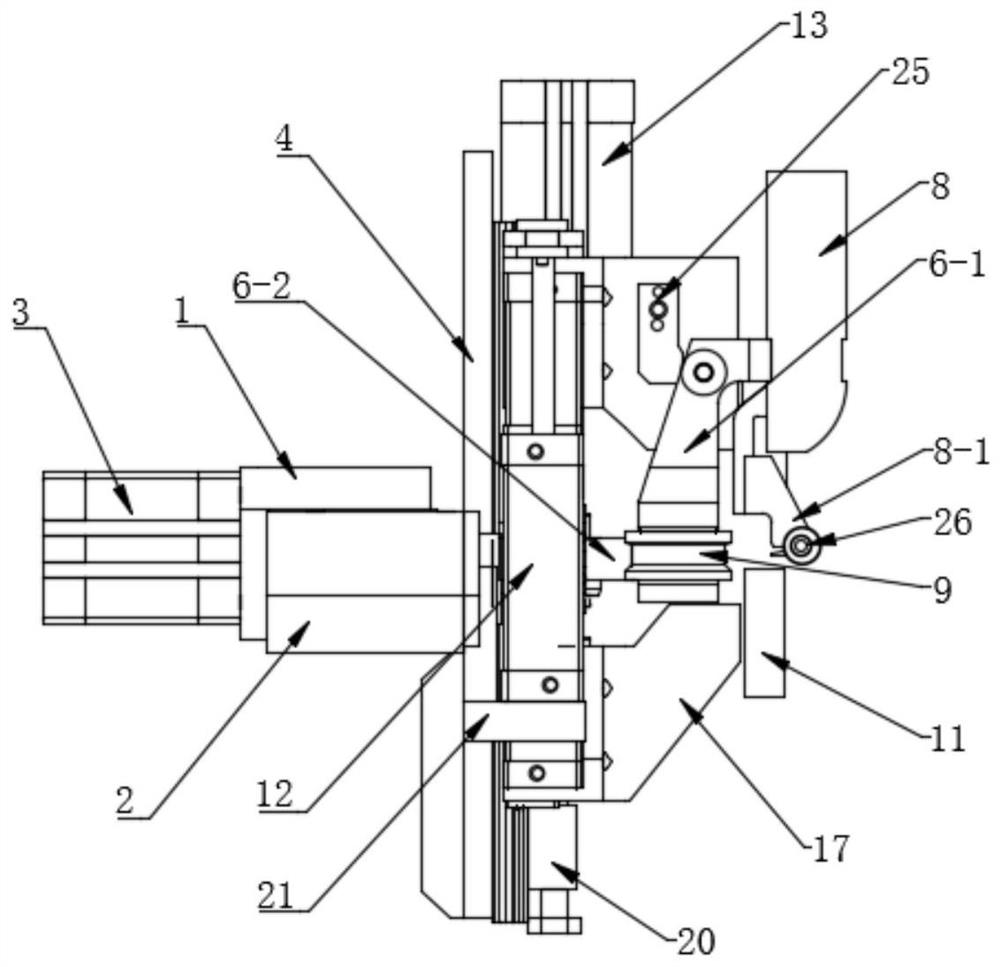

[0038] A kind of card strip automatic installation device, such as Figure 1-4 As shown, it includes an integral propulsion structure fixedly installed with the manipulator, a grasping structure for grabbing the strip to be clamped, and a rolling installation structure for installing the clamped strip on the glass;

[0039] Such as Figure 5 As shown, the overall propulsion structure includes a fixed installation plate 1 fixedly installed with the manipulator, a mobile frame 2 slidingly installed under the fixed installation plate 1, and a push cylinder 3, and the push cylinder 3 is installed on the fixed installation plate 1, its push rod pushes the mobile frame 2 to slide along the fixed installation plate 1, and the vertical connecting plate 4 is fixedly installed on the integral propulsion structure, and the connecting plate 4 is fixed with a Z direction slide rail 5;

[0040] The push cylinder and moving frame provide a flexible compensation device for the whole device,...

Embodiment 2

[0051] This embodiment introduces its installation method on the basis of Embodiment 1.

[0052] The installation method of the above-mentioned card strip automatic installation device mainly includes the following steps:

[0053] The manipulator drives the clip automatic installation device to reach the clip station, the pneumatic clamp 8 starts, and the profiling fixture 8-1 cooperates with the auxiliary roller 9 to grab the clip;

[0054] The manipulator drives the automatic strip installation device to the glass station, the upper pressing roller 10 is located above the glass, and the lower pressing roller 11 is located below the glass;

[0055] The pneumatic clamp 8 is closed, the profiling fixture 8-1 is lifted up, and the clamped strip is placed on the glass, and at the same time, the first clamping cylinder 12 and the second clamping cylinder 13 are activated, so that The upper pressing roller 10 presses the clamping strip downwards, the lower pressing roller 11 clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com