Mark printing machine

A label printing machine and frame technology, applied in the field of clothing manufacturing, can solve the problems of pressure adjustment and different uses of the down-pressing hot plate, and achieve the effects of increasing stability, improving work efficiency, and reducing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

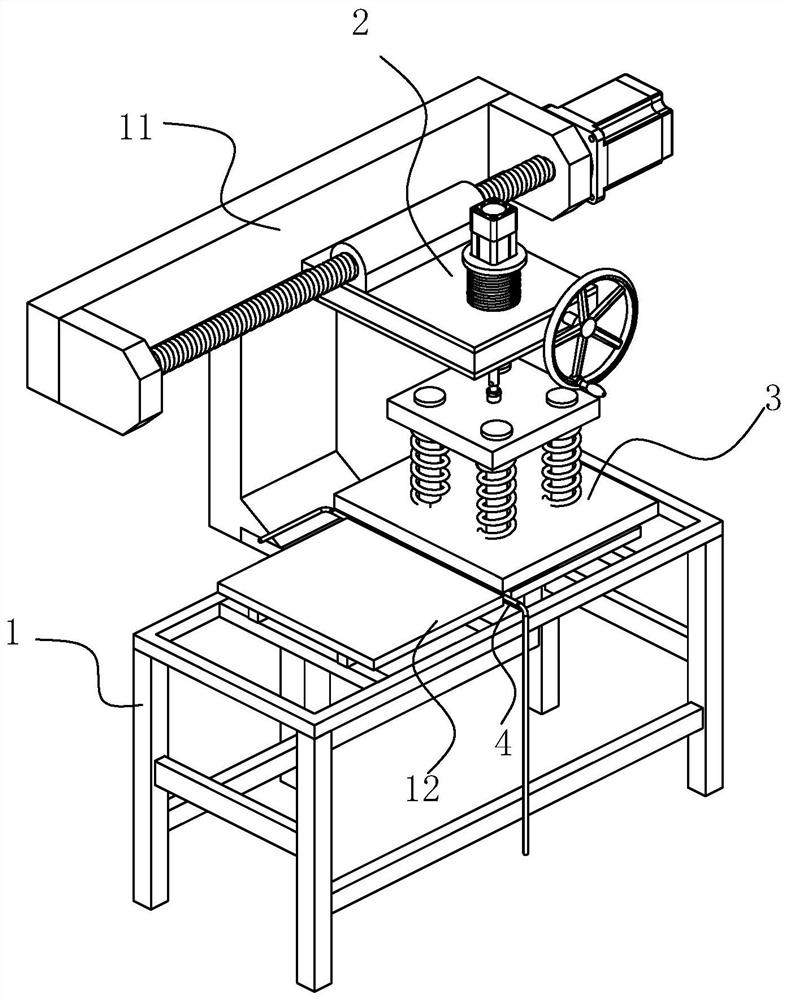

[0034] Embodiment: a kind of marking machine, see figure 1 , including a frame 1 , a moving device 2 arranged at the top of the frame 1 , a heat-pressing device 3 arranged at the bottom of the moving device 2 , and a cooling device 4 arranged on the frame 1 . One side of the frame 1 is fixed with a support frame 11 supporting the mobile device 2, and the top of the frame 1 is fixed with a fixed plate 12, and the number of the fixed plates 12 is two, arranged side by side along the moving direction of the mobile device 2 . The cooling device 4 is arranged at the bottom of the fixing plate 12 to cool the fixing plate 12 .

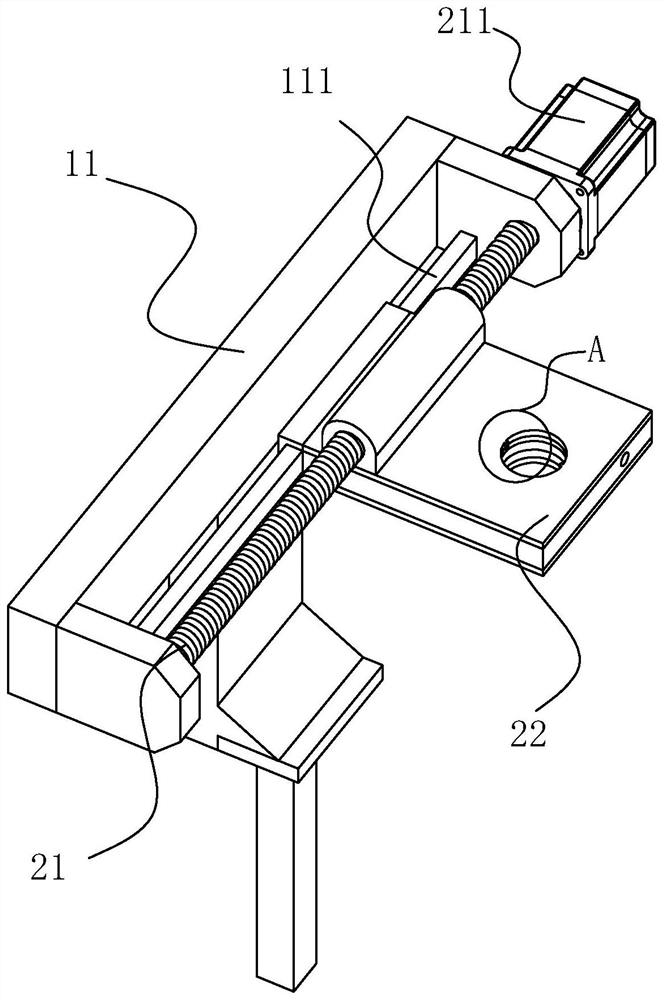

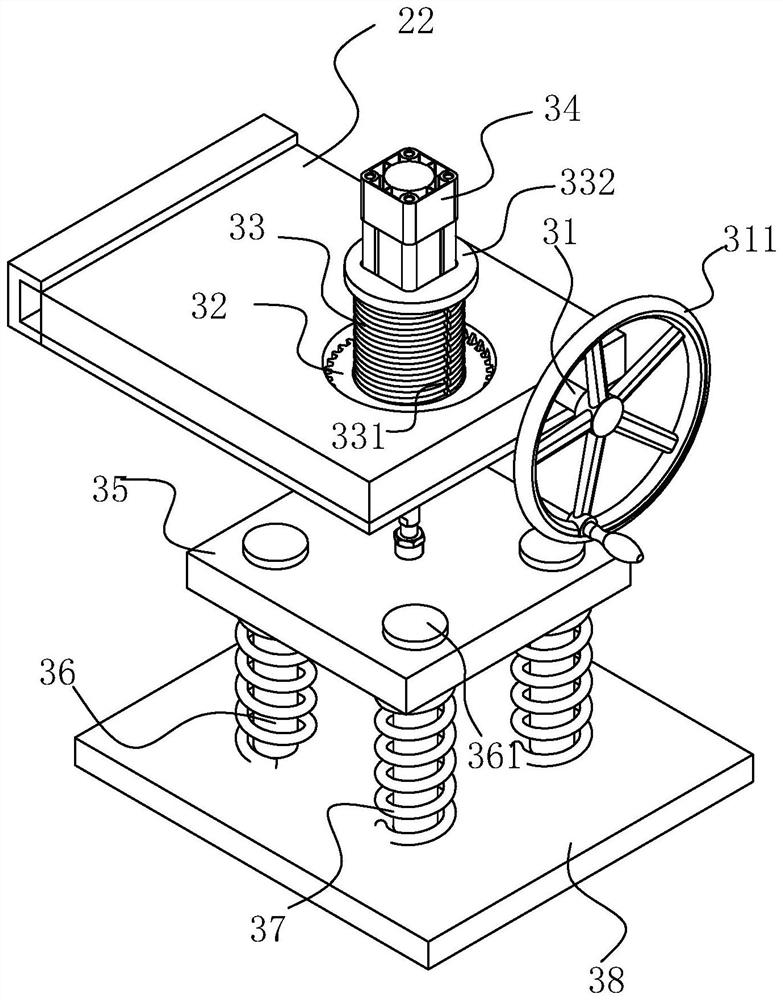

[0035] see figure 2 , the moving device 2 includes a threaded rod 21 rotatably connected to the support frame 11 and a support plate 22 threaded to the threaded rod 21 . The cross-section of the top of the support frame 11 is N-shaped, and the threaded rod 21 is screwed on the top of the support frame 11 and is located in the middle of the N-shaped suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap