Improved anti-collision rubber fender and using method thereof

An improved technology of rubber fender, which is applied in non-rotational vibration suppression, shipping equipment, climate change adaptation, etc., can solve the problems of rubber fender collision damage, ship berthing damage, rubber fender easy damage, etc., to achieve protection Abrasion resistance, guaranteed impact resistance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

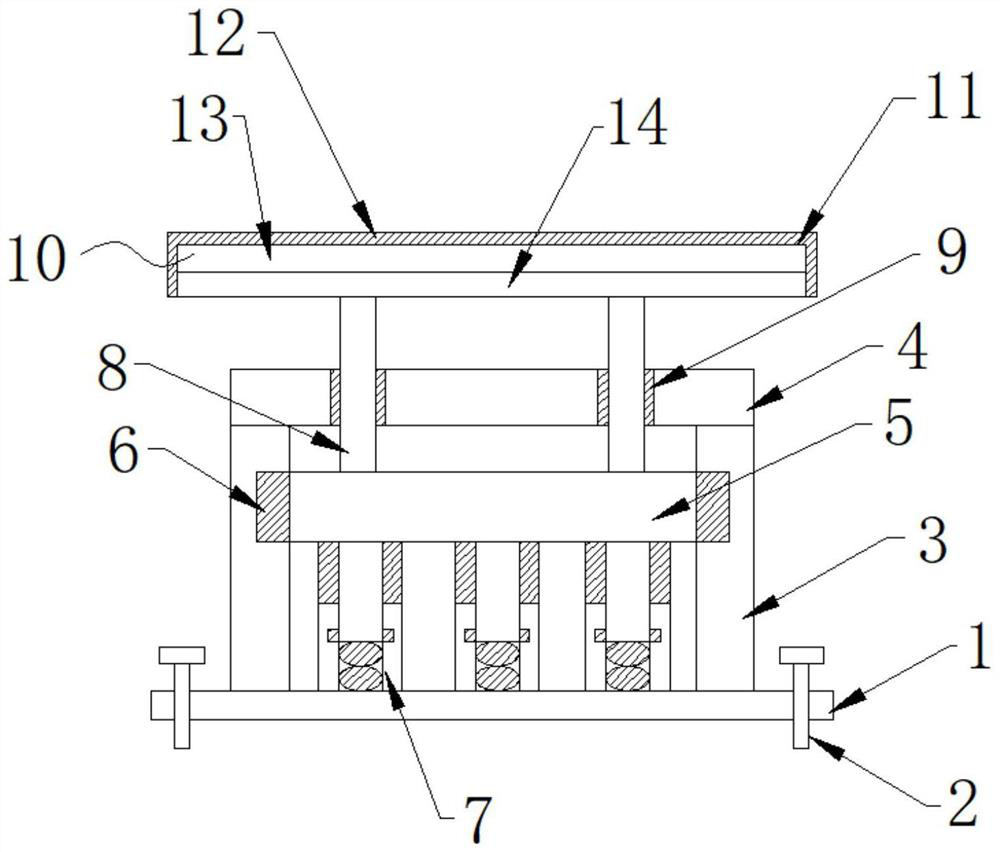

[0023] see figure 1 , the present invention provides a technical solution: an improved anti-collision rubber fender, including a base plate 1, vertical plates 3 are arranged on the left and right sides of the rear end surface of the base plate 1, and the rear end surfaces of two sets of vertical plates 3 are connected with Horizontal plate 4, movable plate 5 is arranged between two groups of vertical plates 3, multiple groups of buffer members 7 are evenly arranged on the front end of movable plate 5, support rods 8 are arranged on the left and right sides of the rear end surface of movable plate 5, and on the horizontal plate 4 The positions corresponding to the two sets of support rods 8 are provided with installation holes, and the inner cavities of the two sets of installation holes on the horizontal plate 4 are provided with guide sleeves 9 that match the support rods 8, and the rear ends of the two sets of support rods 8 pass through the And extend the inner cavity of th...

Embodiment 2

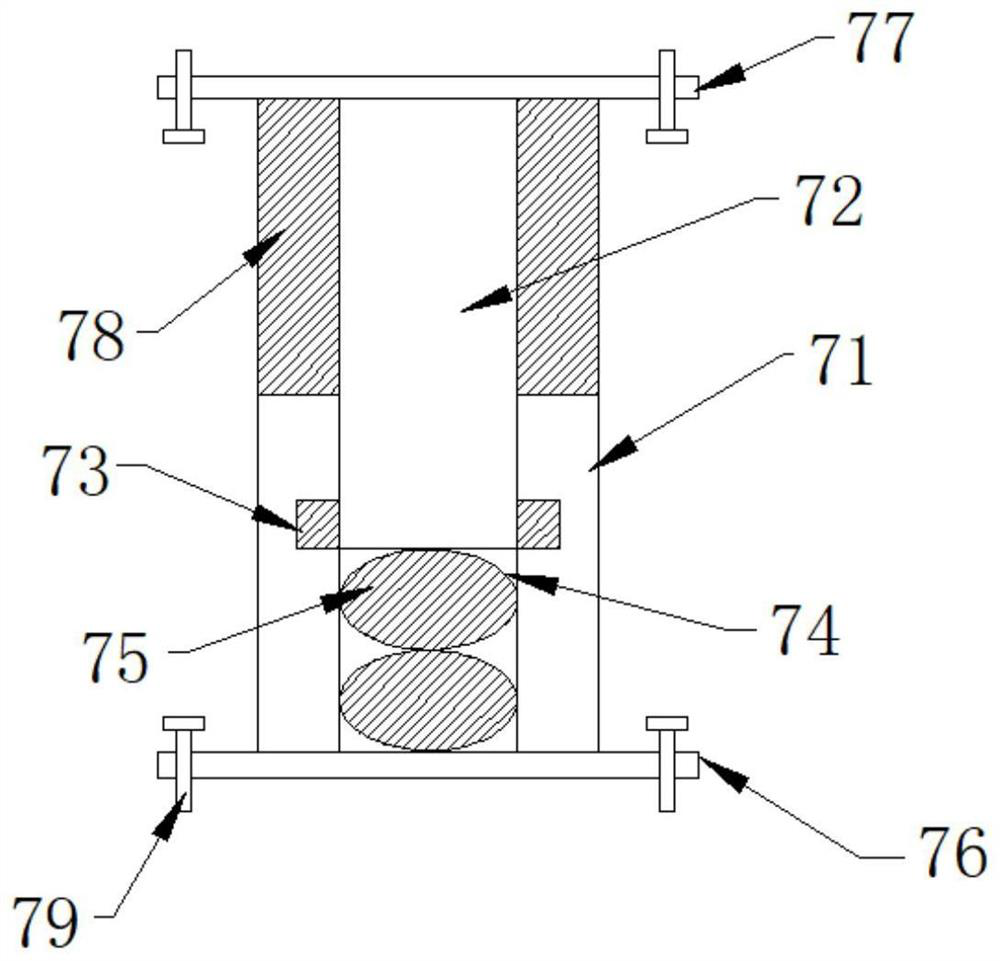

[0032] see figure 2, the inner cavity of the female rod 71 is provided with multiple groups of rubber balls 74, the inner chamber of the rubber balls 74 is provided with a polyurethane filling layer 75, and the outer circumference of the child rod 72 is provided with a soft polyurethane ring 78, and the front surface of the soft polyurethane ring 78 is in contact with the female rod. The rear end surface of the rod 71 is fitted and connected. Compared with Embodiment 1, the beneficial effect achieved by the polyurethane filling layer 75 and the soft polyurethane ring 78 in Embodiment 2 is: the polyurethane material of the soft polyurethane ring 78 and the polyurethane filling layer 75 Stability, chemical resistance, resilience and mechanical properties, as well as smaller compression deformation performance, can have good energy absorption and reaction to the impact force generated by the ship, and can achieve both docking and ships Good buffer protection, meanwhile, the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com