Discontinuous multilayer ore body safe stoping method

A non-continuous ore technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of difficult mining, waste of resources, and abandonment of upper and lower ore bodies, so as to improve mining efficiency, avoid waste of resources, and improve Effect of Mining Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

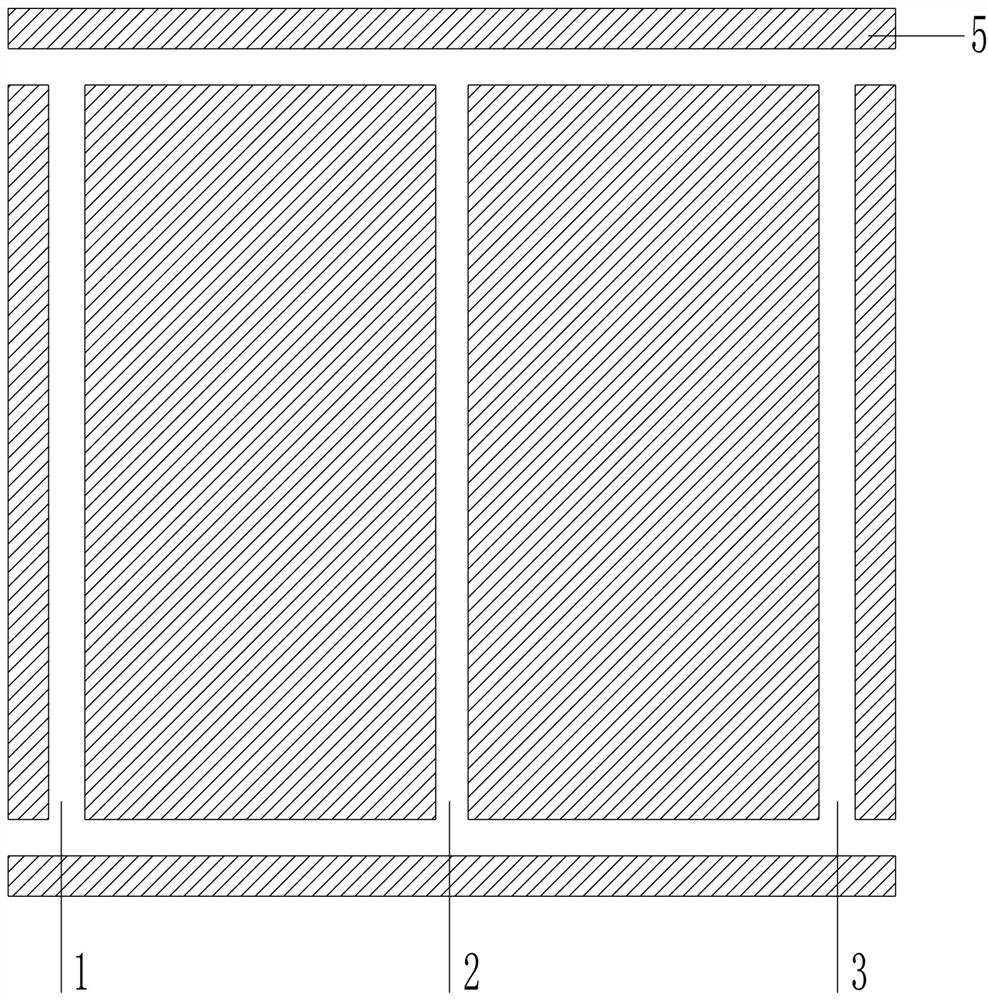

[0042] In the mine house of 60*60 meters, the middle construction cuts the uphill lane 2, the side construction cuts the horizontal lane 1, and the other side construction cuts the downhill lane 3. Construct three cutting roadways to facilitate the mining of the upper, middle and lower layers of ore respectively. The ore in the upper layer is transported through the uphill lane 2, the ore in the middle layer is transported through the level lane 1, and the ore in the lower layer is transported through the downhill lane 3.

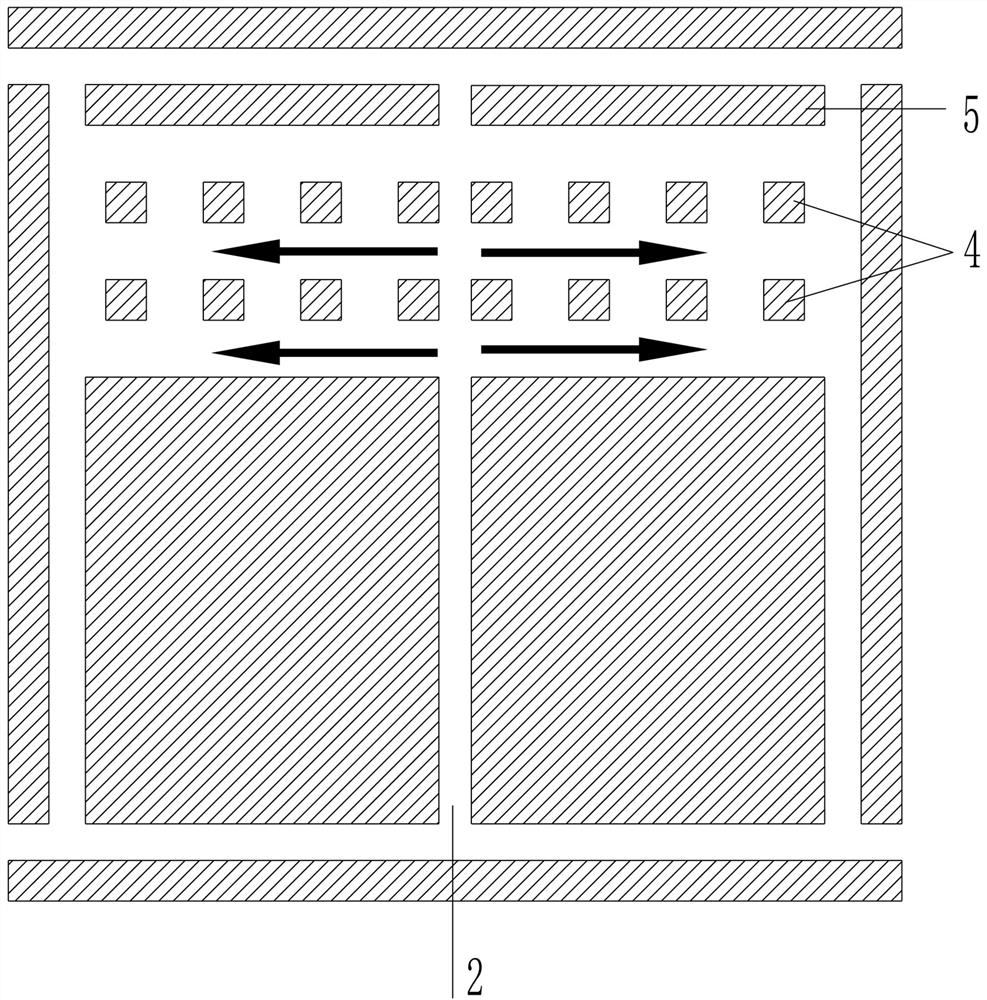

[0043] After the cutting of the roadway is completed, the upper layer of ore is mined first, and the ore pillar 4 is set according to 5*5 meters. After forming 2 rows of ore pillars, stop and then retreat.

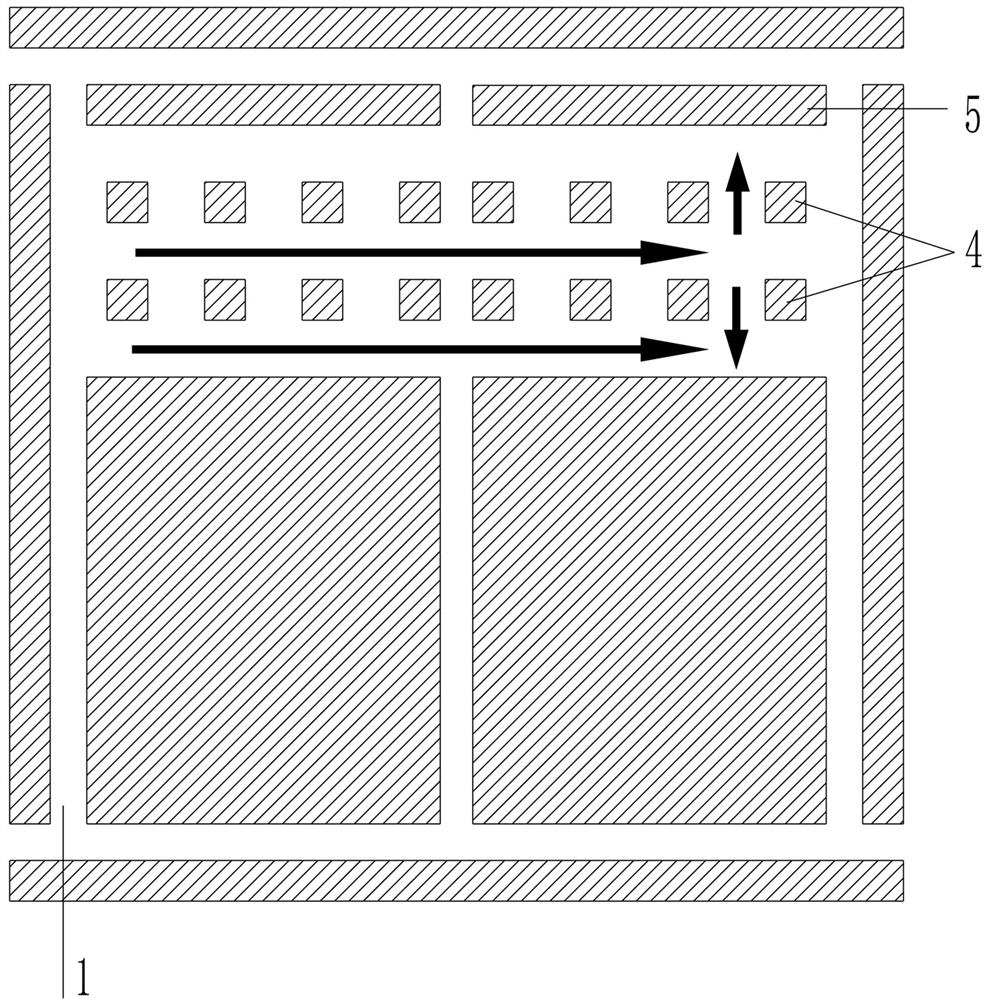

[0044] When the upper layer is mined, the upper mountain roadway 2 cut in the middle is lowered along the bottom roadway to cut the horizontal roadway 1 on one side, and then the second layer of ore is mined according to the room-and-pillar method.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com