Inverse proportion pressure reducing valve

A pressure reducing valve and inverse proportional technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of low control accuracy, achieve the effects of improving control accuracy, improving stability, and mitigating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

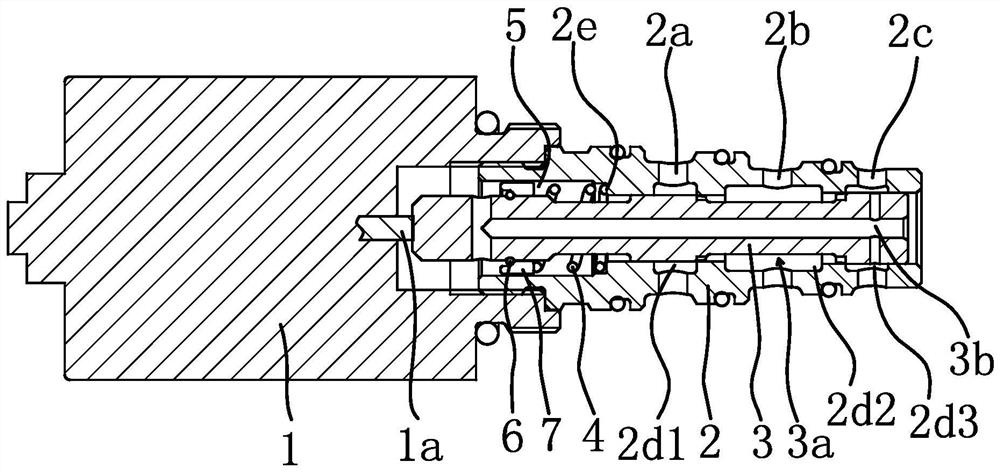

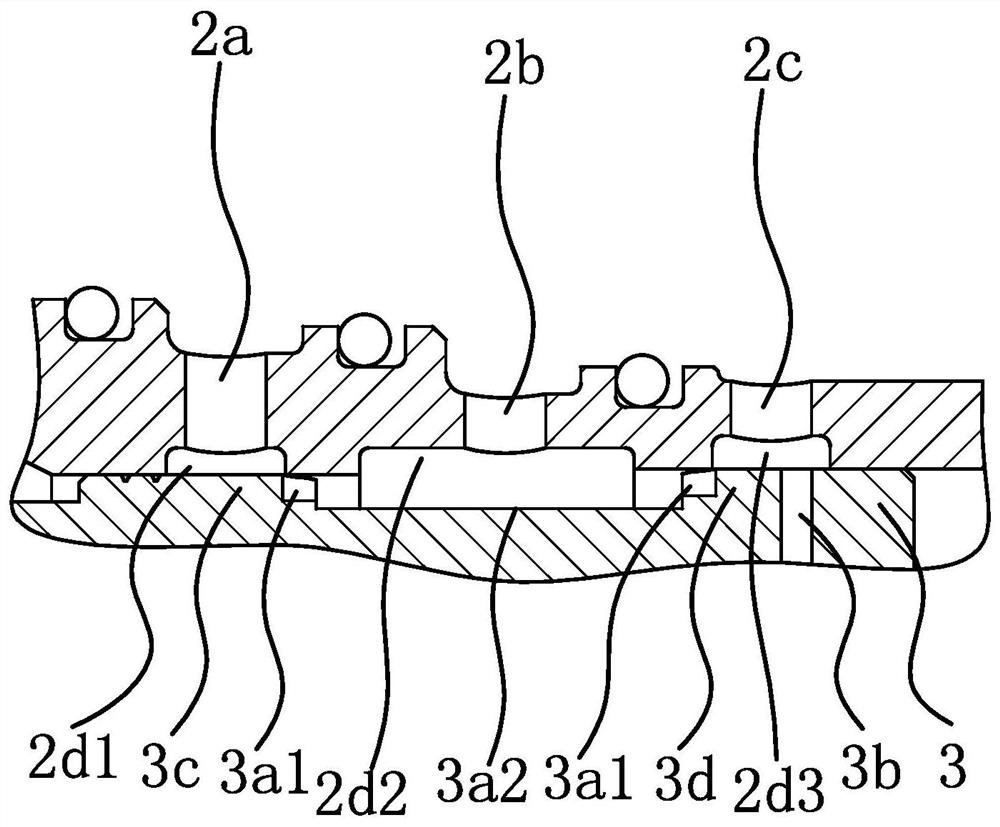

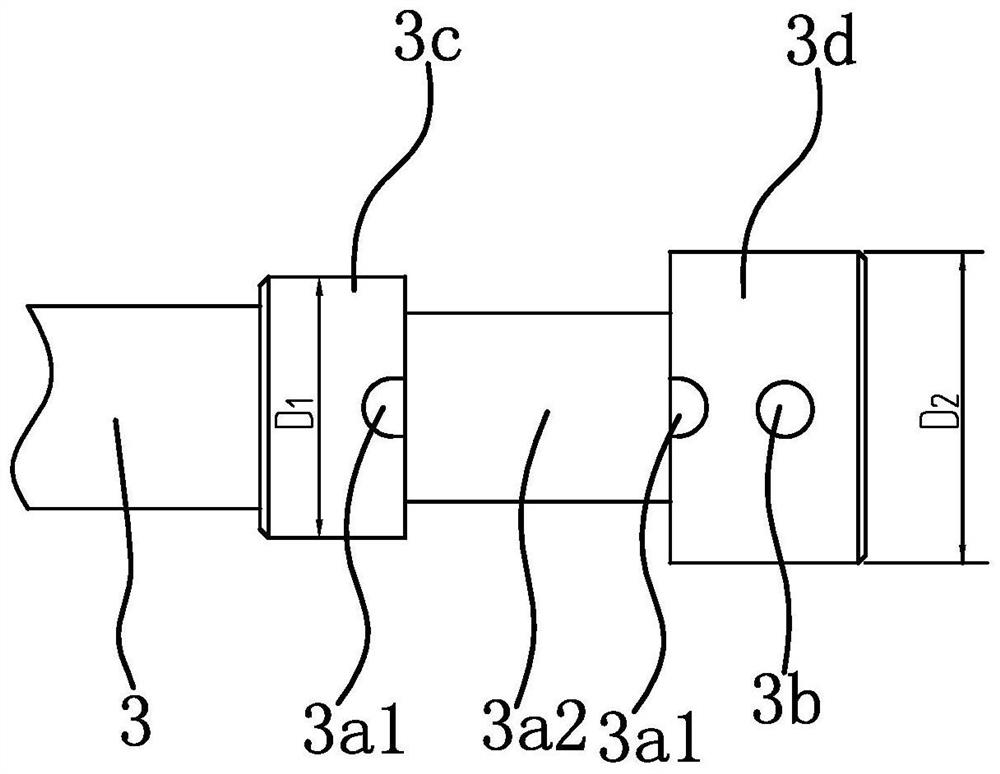

[0031] Such as figure 1 As shown, an inverse proportional pressure reducing valve includes a valve body 2, a valve core 3 located in the valve body 2 that can slide axially, and a spring 4 located between the valve body 2 and the valve core 3, and one end of the valve body 2 is connected with an electromagnetic Iron 1, specifically, one end of the spool 3 is fixed to the electromagnet 1 through threads, and the spool 3 is provided with a through hole for the installation of the spool 3. When the spool 3 is installed in the valve body 2, the valve body 2 A spring cavity 5 is formed between one end close to the electromagnet 1 and the valve body 2. The spring 4 is installed in the spring cavity 5 and the two ends respectively act on the valve body 2 and the valve core 3. More specifically, the electromagnet 1 is provided with There is a push rod 1a, and the electromagnet 1 transmits power to the valve core 3 through the push rod 1a, thereby forming a thrust force opposite to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com