Gear shifting and parking locking mechanism for electric automobile

A technology for electric vehicles and parking locks, applied in mechanical equipment, transmission, transmission control, etc., can solve problems such as misoperation, danger, and damage to the locking mechanism, and achieve accurate shifting, avoid danger, and prevent the car from slipping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

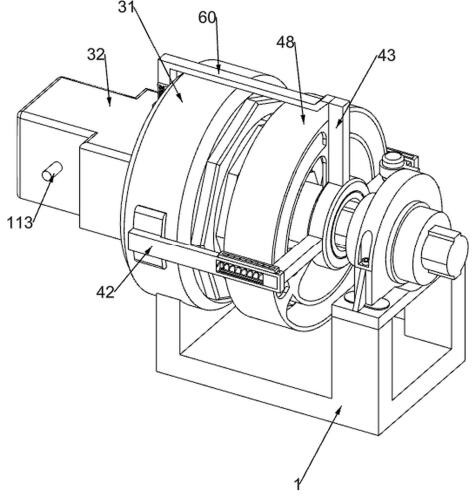

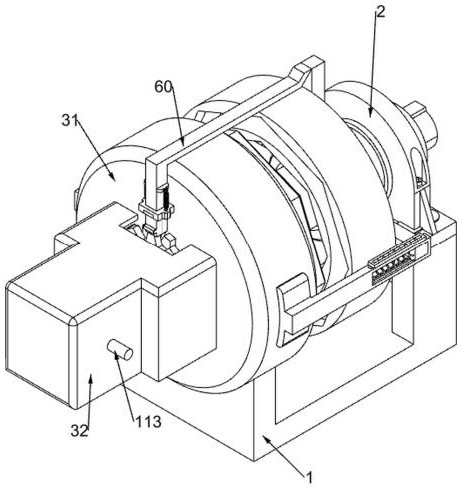

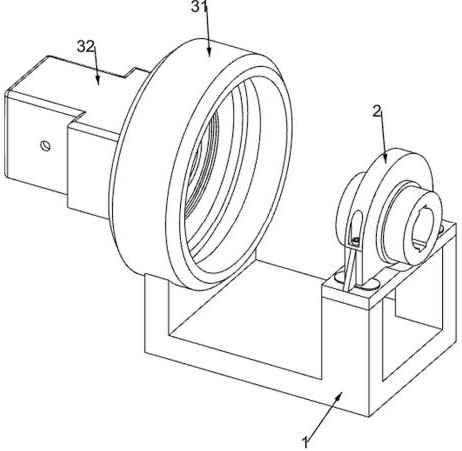

[0038] Gear shift and parking lock mechanisms for electric vehicles, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, it includes a bottom frame 1, a support seat 2, a support outer ring 31, a protective shell 32, a switching assembly 4, a speed change assembly 5 and a locking assembly 6. 1. A support outer ring 31 is fixedly installed on the upper left, and a protective shell 32 is fixedly installed on the left side of the support outer ring 31. A switching assembly 4 is arranged on the support seat 2. The switching assembly 4 is used to switch power, and the support outer ring 31 The upper rotation is connected with a transmission assembly 5, the transmission assembly 5 is used to control the driving speed of the car, and the locking assembly 6 is fixedly installed on the right side of the supporting outer ring ...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 9 As shown, it also includes a trapezoidal locking tooth 2, a sliding locking tooth 2 8 and a second return spring 9, and the trapezoidal locking tooth 2 7 is connected to the outside of the slotted ring 63 in a circumferentially distributed manner, below the wedge-shaped sliding bar 60 Sliding type connection has sliding locking tooth 2 8, sliding locking tooth 2 8 is in contact with one of the trapezoidal locking teeth 2 7, sliding locking tooth 2 8 is used to block the trapezoidal locking tooth 2 7, sliding locking tooth 2 8 and wedge-shaped sliding bar 60 is connected with the second return spring 9.

[0047] When the driver parks the car, the situation that the trapezoidal locking tooth 1 66 may block the sliding locking tooth 1 67, the sliding locking tooth 1 67 cannot block the trapezoidal locking tooth 1 66, so the trapezoidal locking tooth 1 66 will slide the locking tooth When tooth 1 67 is blocked, the second homing...

Embodiment 3

[0049] On the basis of Example 2, such as Figure 11 , Figure 12 and Figure 13 As shown, it also includes an anti-tooth assembly 10, the slotted gear shaft 58 is provided with an anti-tooth assembly 10, the anti-tooth assembly 10 is used to protect the slotted ring 63 and its upper device, the anti-tooth assembly 10 includes a spline threaded shaft 101, a wedge-shaped fixing bar 102, a special-shaped slip ring 103 and a first return spring 104, and the slotted gear shaft 58 is connected with a spline threaded shaft 101 through a threaded connection, and the left side of the clamping rod 64 is fixed A wedge-shaped fixing bar 102 is connected, and a special-shaped slip ring 103 is slidably connected to the slotted gear shaft 58. The wedge-shaped fixing bar 102 is in contact with the special-shaped slip ring 103, and the special-shaped slip ring 103 is used to push the wedge-shaped fixing bar 102 and the clamp rod 64 to move relative to each other. , The special-shaped slip r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com