Construction method for energy-gathered water pressure blasting

A hydraulic blasting and construction method technology, applied in blasting, blasting barrels, earthwork drilling and mining, etc., can solve the problems of surrounding rock damage, difficulty in controlling the peak stress of surrounding rock, low utilization rate of explosive energy and blasthole utilization, etc., to achieve enhanced The fracture surface is formed, the blasting effect is controllable, and the effect of improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

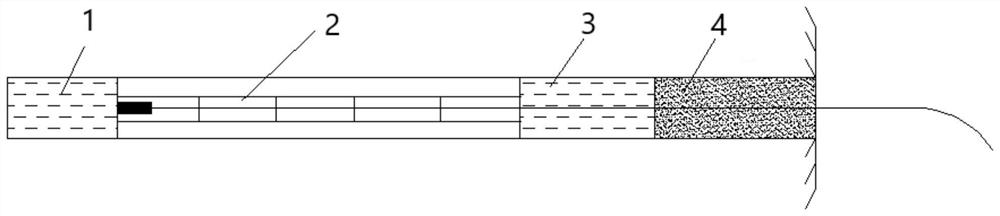

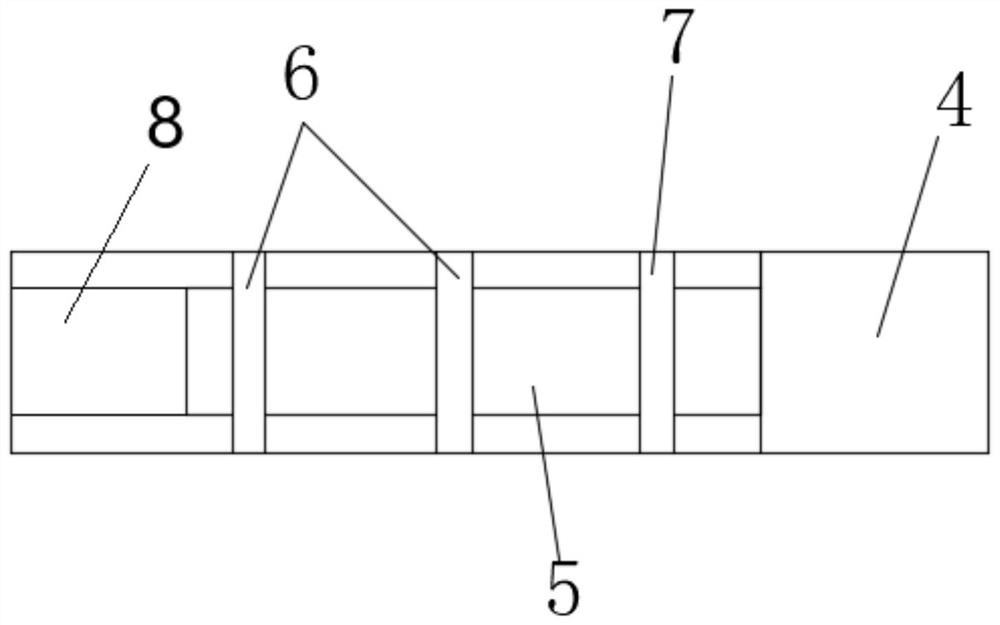

[0054] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments, wherein the same reference numerals in the accompanying drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

[0055] The description of the embodiments should be detailed, so that those skilled in the art can realize the technical solution without creativity. Embodiments may be one or more, depending on the specific circumstances to support the claimed scope.

[0056] For the invention of a pair of products, the specific implementation method shall describe in detail the mechanical structure of the product in conjunction with the accompanying drawings, explain the mutual relationship between each component, such as the connection relationship and cooperation relationship between them, and when necessary, also explain its ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com