Valve inner leakage rate evaluation device and grade evaluation method

An evaluation device and a technology for evaluating grades, applied to measuring devices, by detecting the appearance of fluid at the leakage point, and by measuring the increase and deceleration rate of the fluid, etc., it can solve the problems of dependence on measurement and detection, failure to classify and diagnose valve leaks, etc., to achieve Ease of implementation, avoidance of economic losses, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

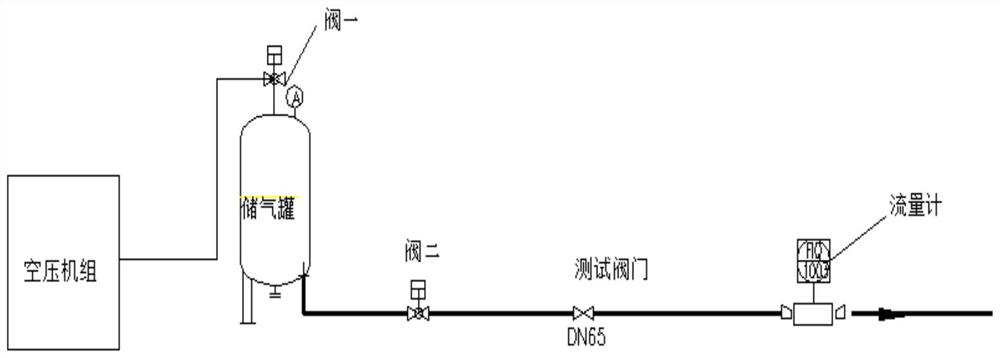

[0073] A valve internal leakage leakage rate evaluation grade method, which uses a valve internal leakage leakage rate evaluation device, including an air storage tank, an air compressor, valve two, a flow meter and a test valve, and the air compressor is used for air storage tanks. Stamping, the pipeline connected between the gas storage tank and the flow meter is provided with the valve 2 and the test valve in sequence, the test valve is equipped with an acoustic sensor, and the acoustic sensor is connected to an acoustic sensor through a data line. Acquisition equipment; a pressure gauge is installed on the gas storage tank, and when the air compressor punches the gas storage tank, the pressure value is monitored through the pressure gauge.

[0074] The evaluation grade method of valve internal leakage leakage rate specifically includes the following steps:

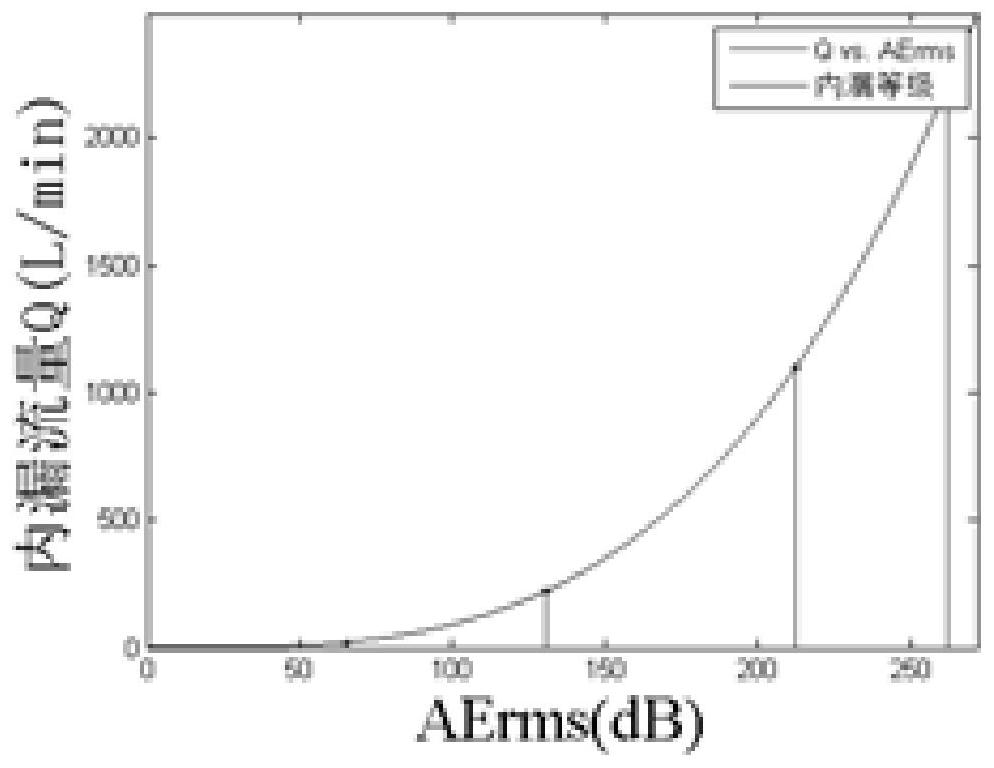

[0075] The first step is to measure the acoustic parameter AErms through the acoustic sensor, and measure the intern...

Embodiment 2

[0079] Valve internal leakage leakage rate evaluation device, including air storage tank, air compressor, valve two, flow meter and test valve, the air compressor is used to press the air storage tank, and the connection between the air storage tank and the flow meter The second valve and the test valve are arranged in sequence on the pipeline, and an acoustic sensor is installed on the test valve, and the acoustic sensor is connected to an acoustic acquisition device through a data line; a pressure gauge is installed on the gas storage tank. When the air compressor described above punches the air storage tank, the pressure value is monitored by the pressure gauge described above.

[0080] According to "GBT 4213-2008 Pneumatic Control Valve" and "GBT17214.2-2005 Industrial Process Control Valve Part 5-1", the formula for calculating the rated capacity of the valve is shown in the table below.

[0081] Table 1 Calculation formula of valve rated capacity

[0082]

[0083] Am...

Embodiment 3

[0111] Valve internal leakage leakage rate evaluation device, including air storage tank, air compressor, valve two, flow meter and test valve, the air compressor is used to press the air storage tank, and the connection between the air storage tank and the flow meter The second valve and the test valve are arranged in sequence on the pipeline, and an acoustic sensor is installed on the test valve, and the acoustic sensor is connected to an acoustic acquisition device through a data line; a pressure gauge is installed on the gas storage tank. When the air compressor described above punches the air storage tank, the pressure value is monitored by the pressure gauge described above.

[0112] On the basis of Example 2, the test valve is a gate valve at 0.1 MPa as an example.

[0113] Pressurize using a compressor. The test pressure is tested at 0.1MPa. The test uses a DN65 gate valve. The leakage flow rate is adjusted by adjusting the opening of the gate valve. It is measured by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com