Experimental device for frictional loss between high-strength high-speed rail contact wire and pantograph

A contact wire and friction loss technology, which is applied in the field of experimental devices for friction loss between high-strength high-speed rail contact wires and pantographs, can solve problems such as pantograph constraints, and achieve a high degree of improvement, strong practicability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

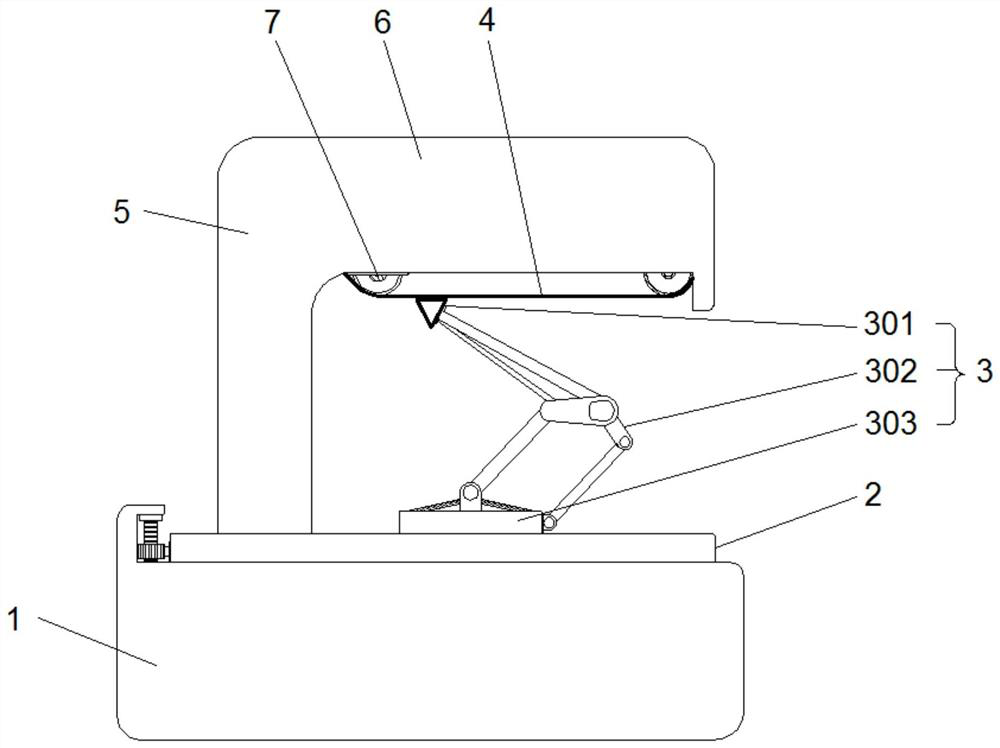

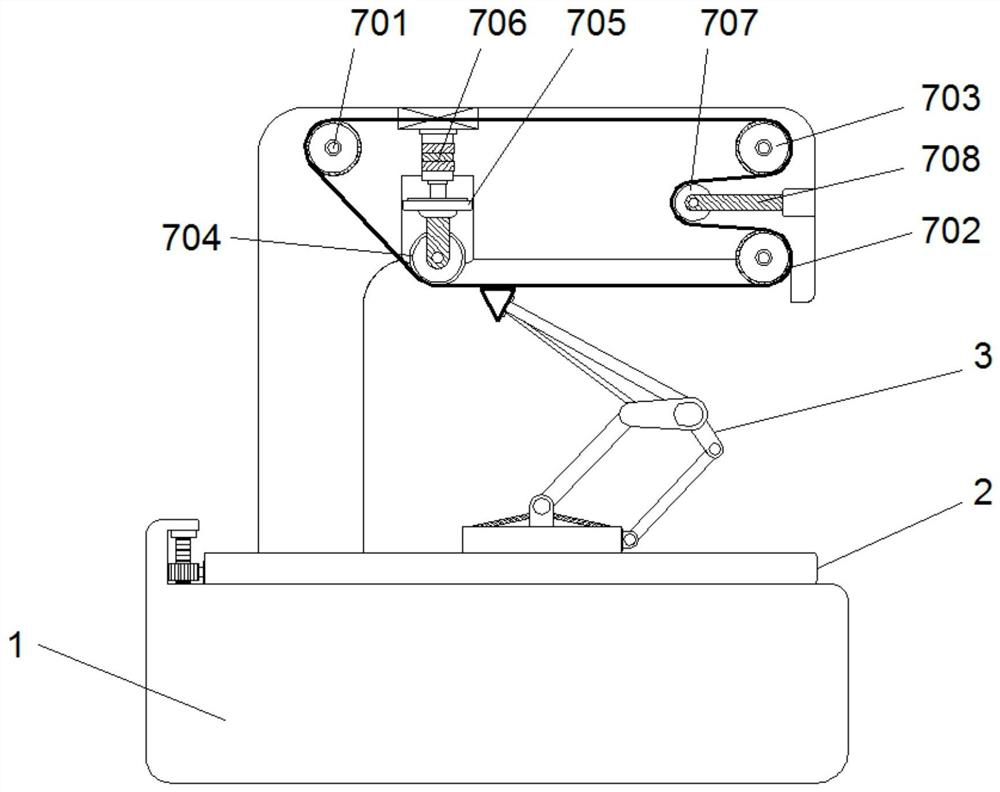

[0030] See Figure 1 ~ 4, Embodiments of the present invention, high strength and high iron contact wires and frictional losses between the experimental apparatus by a pantograph, comprising a base 1, an upper end of the base 1 is provided with a platen for placing test pantograph assembly 3 2, receiving the base 3 of the pantograph assembly 303 fixed to the platen 2 in the experimental holding the upper end surface of the slider 3 pantograph assembly 301 fixed to the base 303 of the upper end, the upper end of the slider 301 by contacting the support with a test lead boom 4 302, the experiments lead top plate 6 is mounted in the rotational direction of the transmission conductors 3 opposite to the conducting component pantograph assembly 7, the conducting wire assembly 7 mounted on a machine base 4, the top plate 6 is fixed by the stand 5 provided on the base 1, experiments lead wire 4 is driven transporting unit 7 and the high speed rotation and continuous frictional contact with...

Embodiment 2

[0039] See Figure 5 ~ 7 Travel, embodiments of the present invention, in Example 1, to further enhance the high strength and high iron contact wires and the degree experimental frictional losses between the pantograph analog high-speed travel during work, so that the pantograph assembly 3 is subjected to simulated Britain woman on the line, vibration, in particular:

[0040] The base 1 is also provided with conducting wire 7 synchronizing component, high-speed analog encounter bumps, the shock bumps vibrating assembly situation, the experiment can be provided with vertically movable upper platen 2 movable plate 203, by pantograph assembly 3 is provided with an elastic material fixed to the clamping plate 204 in contact with the lower end surface of the movable plate, the movable plate 203 is 203, the contact plate 204 is provided below the box 23 pushing, pushing down box 23 may be disposed below the contact plate 204, pushing the box 23 with the contact plate 204 spaced apart, pu...

Embodiment 3

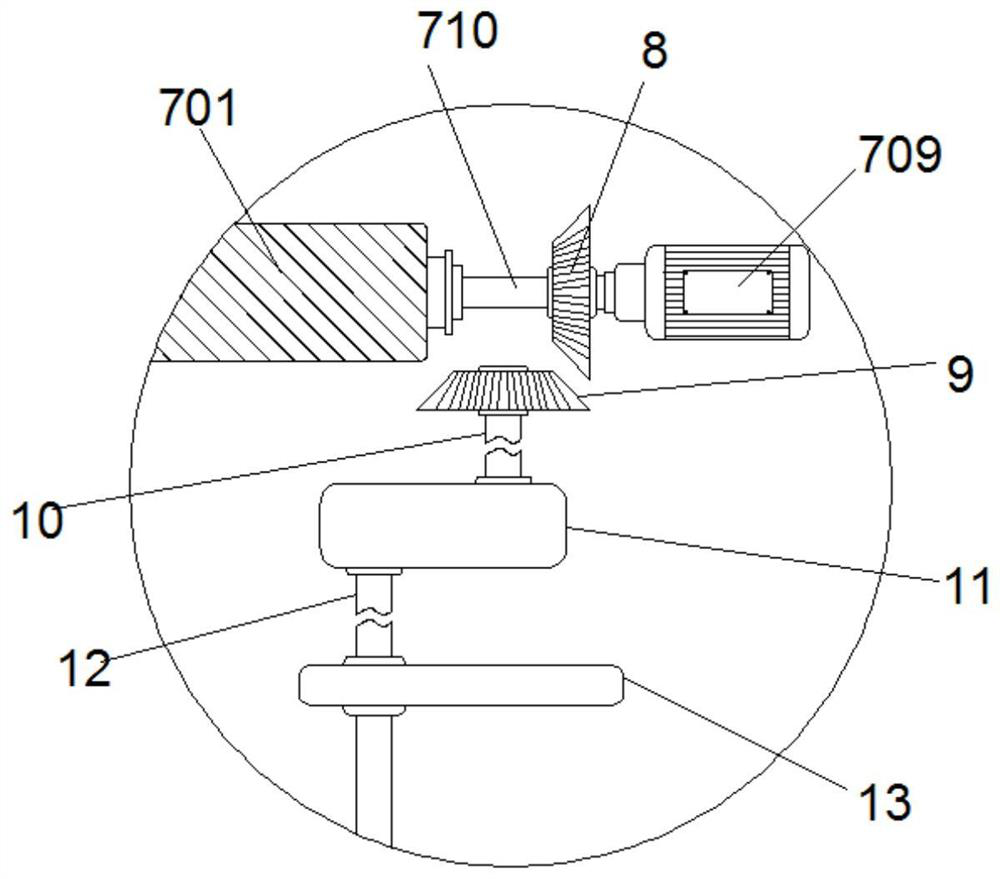

[0045] On the basis of the first embodiment, the embodiment of the present invention is upgraded to the experimental device of the high-intensity high-speed rail contact wire and the electrical shift loss, specifically:

[0046] The first rotating shaft 710 in the wire instruction assembly 7 also has a data acquisition device, which is a speed detector, a mileage detector, a timer, and the like, and integrated through an existing speed, mileage. Get the speed and total mileage of the friction of the electroded arch assembly 3 and the experimental wire 4, which is easy to provide the necessary data parameters to subsequent friction loss experiments to ensure the accuracy of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com