Evaluation method for directly obtaining edge recarburization of continuous casting billet

An evaluation method and technology of continuous casting slabs, which are applied in the preparation of test samples, measuring devices, and material analysis through optical means, can solve the problems of low detection accuracy and complicated detection methods, and achieve high detection accuracy and improved Accuracy and comprehensiveness, the effect of ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The steps of the evaluation method for directly obtaining the carburization of the edge of the continuous casting slab in the embodiment of the present application will be described in detail below.

[0034] An evaluation method for directly obtaining the carburization of the edge of the continuous casting slab, comprising the following steps:

[0035] 1) Sample preparation:

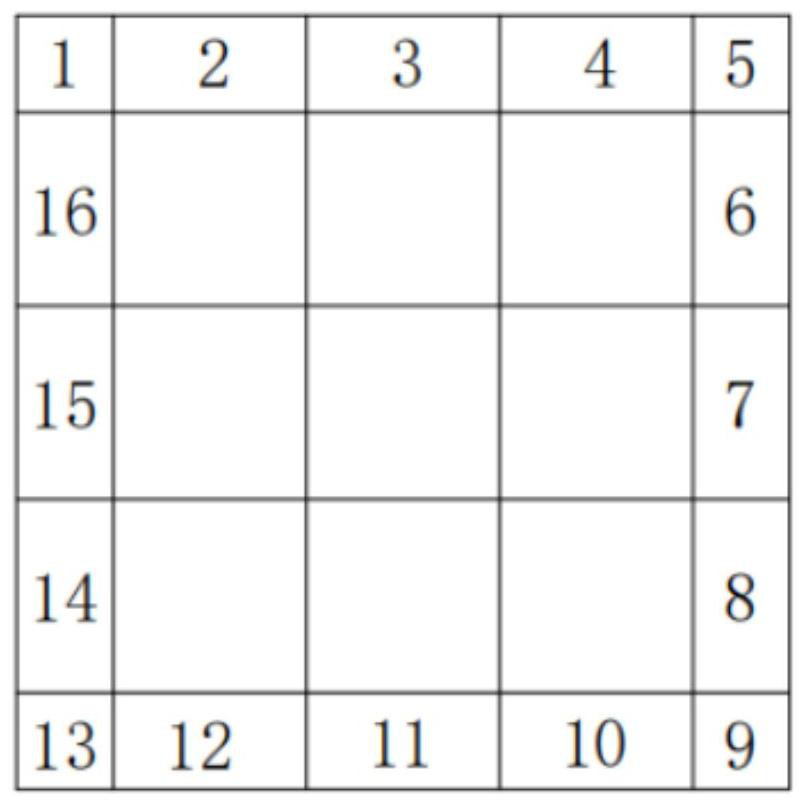

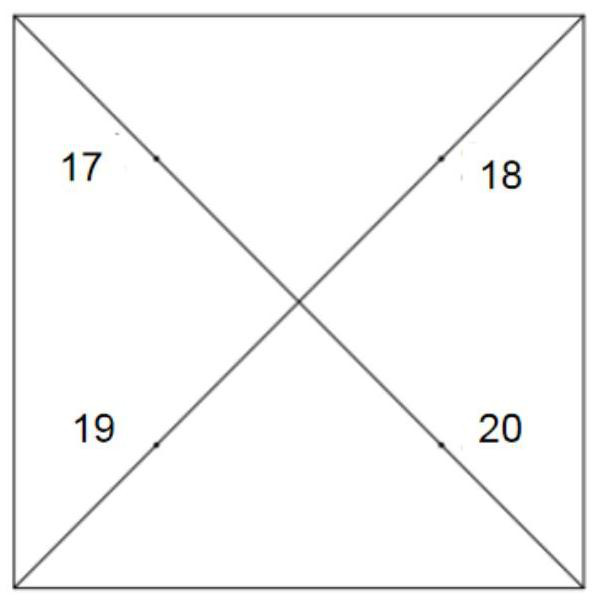

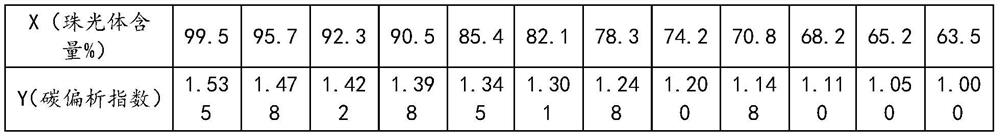

[0036] Select a 160mm continuous casting billet of 45 steel, take a 10mm thick transverse sample from the continuous casting billet, divide it into 4 pieces of 20mm*20mm, 12 pieces of 40mm*20mm small samples, and number the samples in sequence (4 pieces of 20mm *20mm numbers are 1, 5, 9, 13, and other numbers are 40mm*20mm small samples, numbers 1-5 correspond to the inner arc of the billet; numbers 9-13 correspond to the outer arc of the billet), a total of 16 block, and correspond to the position of the slab (inner and outer arcs), such as figure 1 Shown; The ratio of the sampling area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com