Transfer trolley positioning calibration device and calibration method thereof

A technology for calibration devices and transfer vehicles, which is applied to electromagnetic radiation induction, record carriers used by machines, instruments, etc., can solve problems such as difficult maintenance, long transfer paths, and long distances, so as to avoid positioning errors and achieve accurate stop in place Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

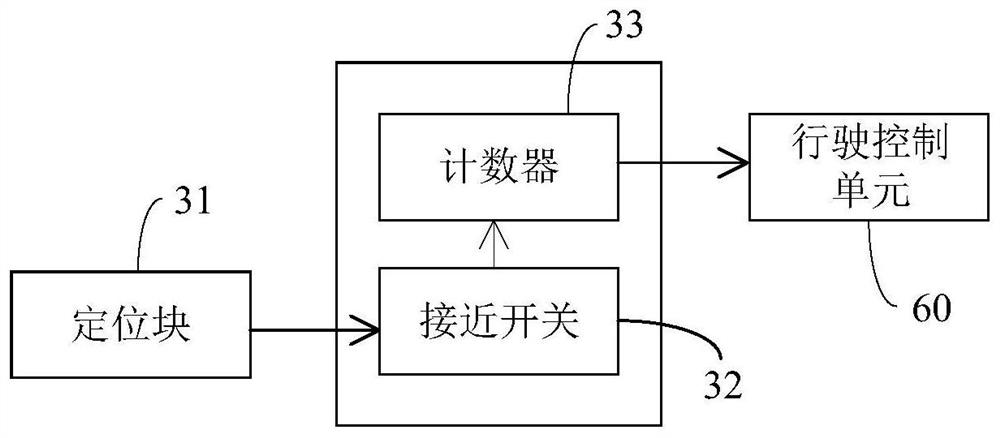

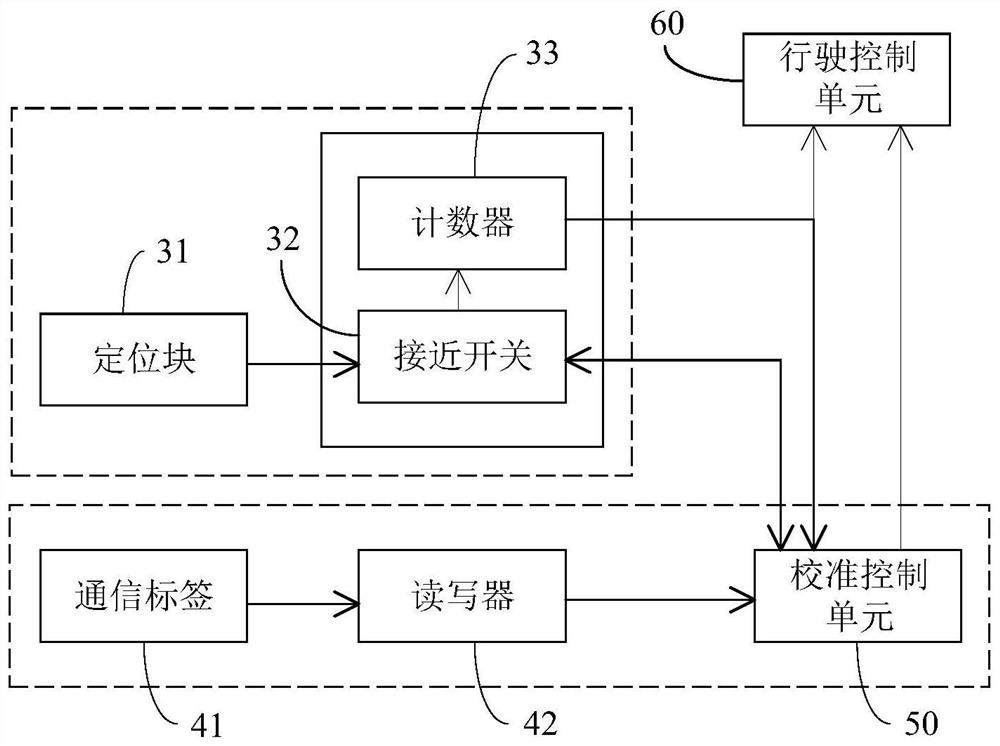

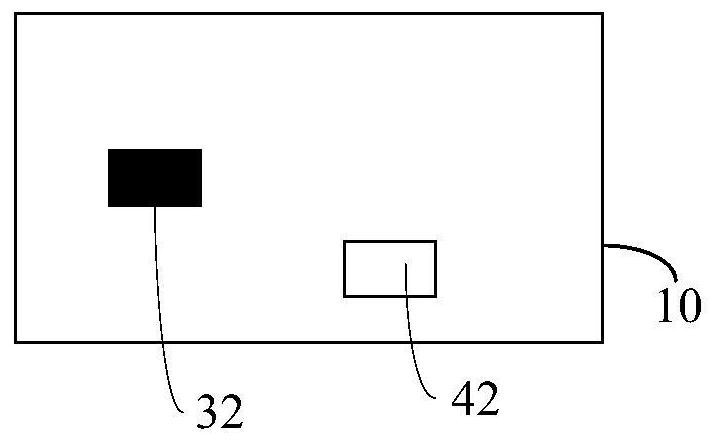

[0015] A transfer vehicle positioning and calibration device, the transfer path of the transfer vehicle 10 includes a calibration section 21 and a transition section 22, the calibration section 21 is provided with a calibration component group, the calibration component group includes adjacently arranged positioning blocks 31, communication tags 41, and the transfer vehicle 10 is correspondingly provided with a proximity switch 32 and a reader-writer 42 , and positioning blocks 31 or communication tags 41 are arranged at intervals in the transition section 22 . The output terminals of the proximity switch 32 and the reader-writer 42 are connected to the calibration control unit 50, and the calibration control unit 50 receives and processes the data uploaded by the proximity switch 32 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com