Integrated cooling battery box body, battery pack and vehicle

A box and battery technology, used in batteries, secondary batteries, battery pack components, etc., can solve problems such as threats to battery safety and poor cooling effect of thermal management systems, improve service life, and solve insulation resistance values. The effect of reducing or even short-circuiting and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

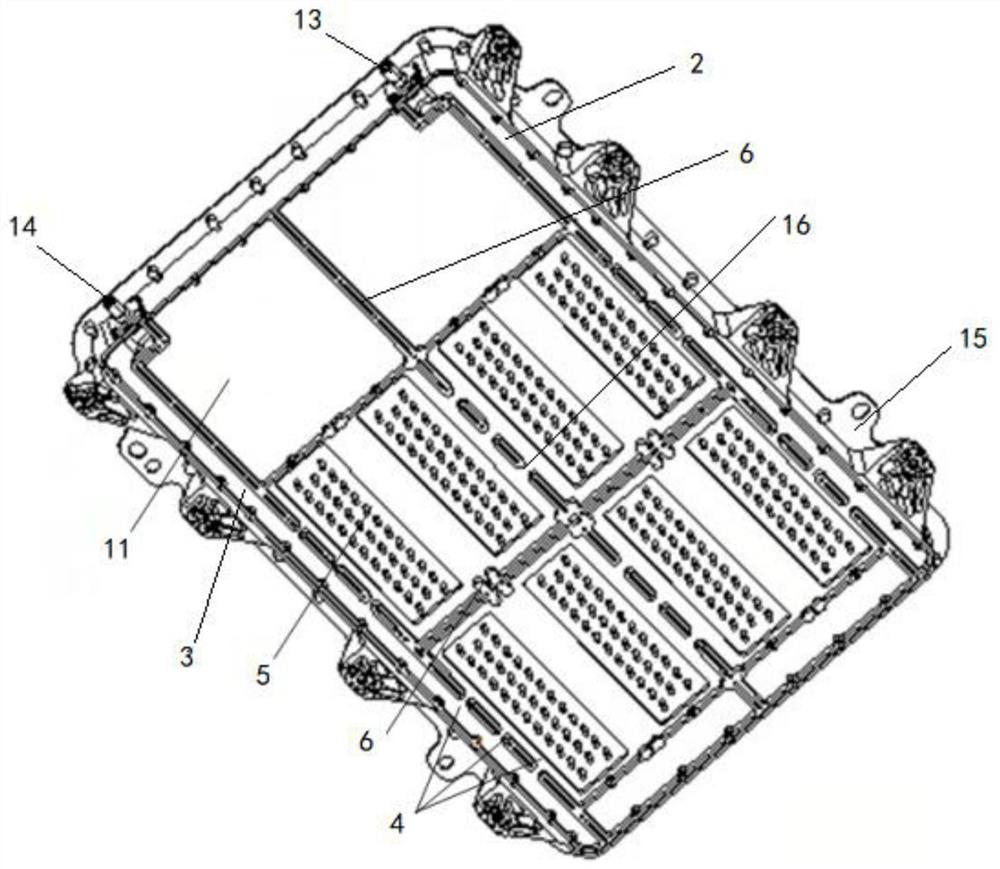

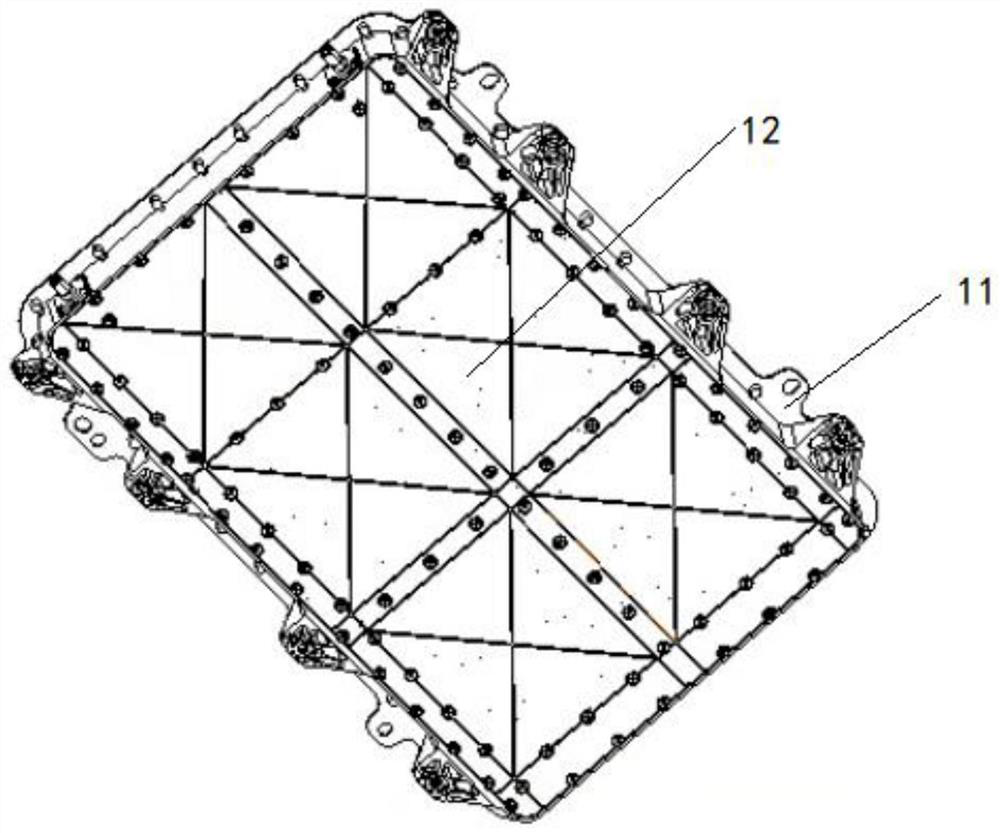

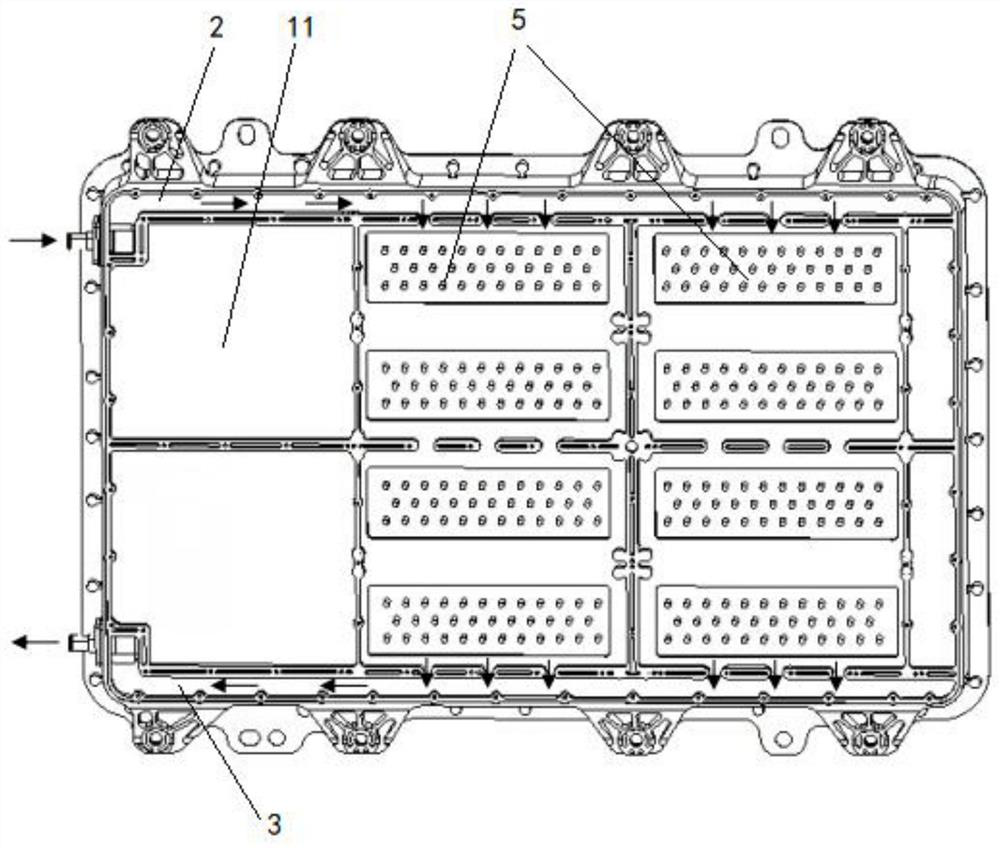

[0043] Based on the same inventive concept, this embodiment provides a battery pack, including the battery and the integrated cooling battery case 1 provided in Embodiment 1; the batteries of the battery pack are installed in the battery chamber of the integrated cooling battery case 1, and the integrated cooling battery The shape and size of the box body 1 can be designed according to the number of batteries, and there is no limitation here.

[0044] The battery is installed in the battery chamber of the integrated cooling battery box 1 through the second box body 11. In order to improve the heat dissipation and cooling effect, a layer of heat conduction pad, such as silicon rubber, can also be laid between the battery and the second box body 11. The heat conduction pad can be The heat generated by the battery is quickly transferred to the second box body 11 and the heat is conducted away through the cooling liquid in the cooling cavity, so as to realize rapid cooling of the b...

Embodiment 3

[0047] Based on the same inventive concept, the present invention also provides a vehicle, including the battery pack provided in Embodiment 2, that is, adopting the integrated cooling battery case 1 in Embodiment 1. The present invention does not specifically limit the type and type of the vehicle. It can be any vehicle in the prior art, such as a family car, passenger car, truck, etc. Other unspecified structures of the vehicle can refer to relevant disclosures in the prior art. , no expansion description will be made here.

[0048] In the vehicle provided in this embodiment, the battery case 1 is connected to the vehicle water tank through the liquid outlet 14 and the liquid inlet 13, and a radiator and a heat dissipation valve are arranged in the vehicle cooling circuit, and the radiator and the heat dissipation valve are connected in series; During the process, the embodiment of the present invention can use the radiator to control the cooling flow according to the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com