Liner for cardboard and manufacturing method of liner for cardboard

A technology of corrugated paper and cardboard, applied in the direction of paper, papermaking, special paper, etc., can solve the problems of overall hardening of cardboard, broken creasing lines, high cost of chemicals, etc., and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0081] The present invention is not limited to the above-described embodiments, and can be implemented in various modified and improved forms other than the above-described forms.

[0082] For example, the containerboard for corrugated cardboard may include a single or a plurality of intermediate layers between the undersurface layer and the backside layer.

Embodiment 1

[0097] The raw materials listed in the table were added to the liquid slurry.

[0098] (additive)

[0099] (1) Rosin-based sizing agent

[0100] Harima Chemical Co., Ltd. "NS-77P" special rosin sizing agent (solid content 50%)

[0101] (2) Acrylamide paper strength enhancer

[0102] Harima Chemicals Co., Ltd. "Harmaid RB-520": two-ionic polyacrylamide (solid content 20%)

Embodiment 2~ Embodiment 7 and comparative example 1~5

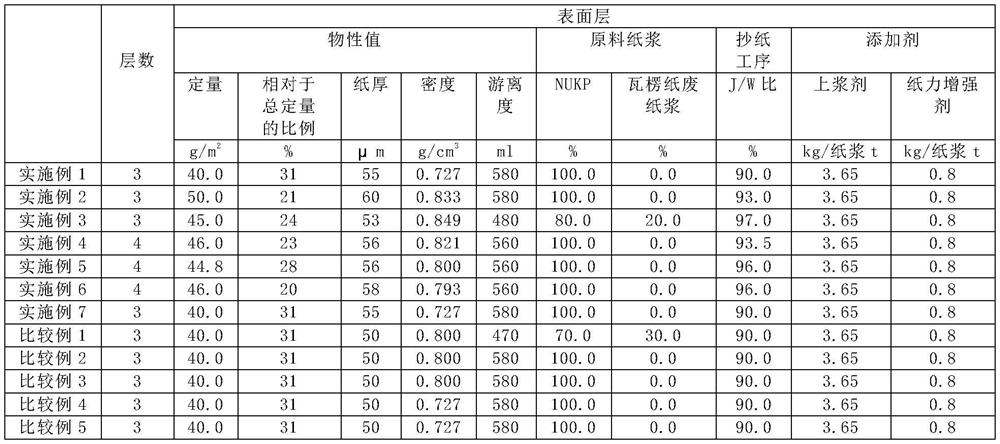

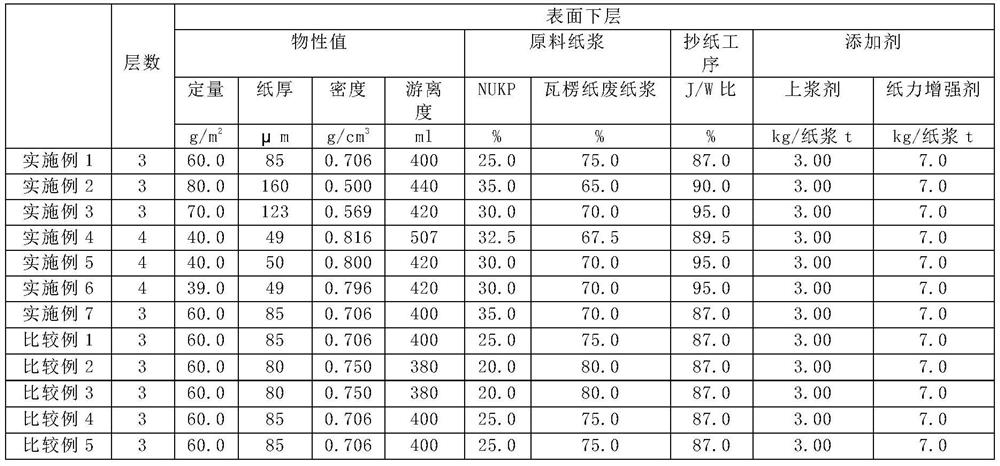

[0104] Examples 2-6, Comparative Examples 1-5, and reference corrugated cardboard were obtained in the same manner as in Example 1 except that the types, addition amounts, and physical properties of the raw materials were shown in Tables 1 to 4. In addition, "one" in the following Table 1 and Table 2 shows that this component was not used. In addition, Examples 2 to 6 include a second back layer.

[0105] 【Table 1】

[0106]

[0107] 【Table 2】

[0108]

[0109] 【table 3】

[0110]

[0111] 【Table 4】

[0112]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Freeness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com