A frame type bone joint prosthesis and its preparation method and application

A bone joint and frame type technology, applied in the field of frame type bone joint prosthesis and its preparation, can solve the problems of complicated operation and high risk, and achieve the effects of simple operation, prolonging the action time and delaying the release time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

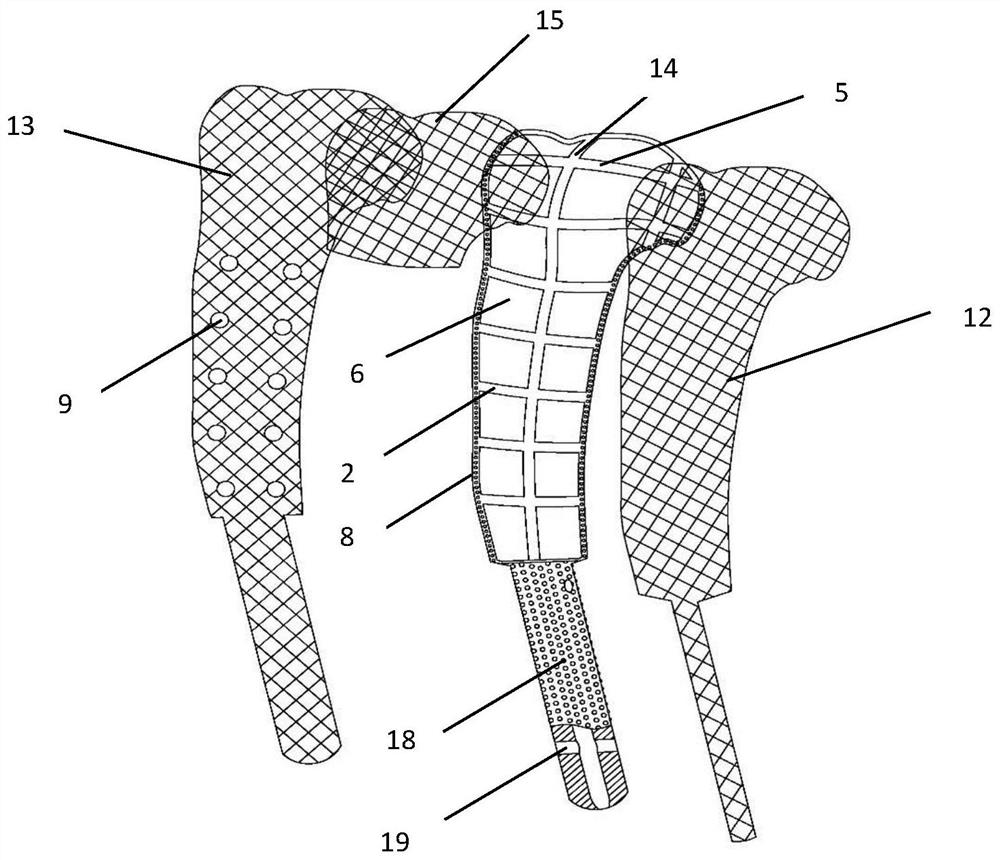

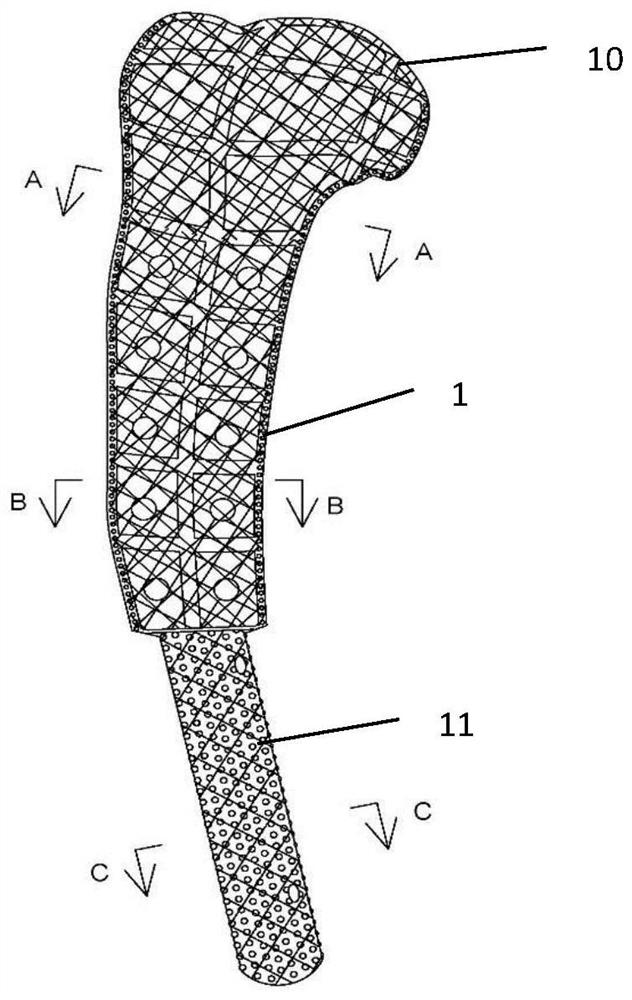

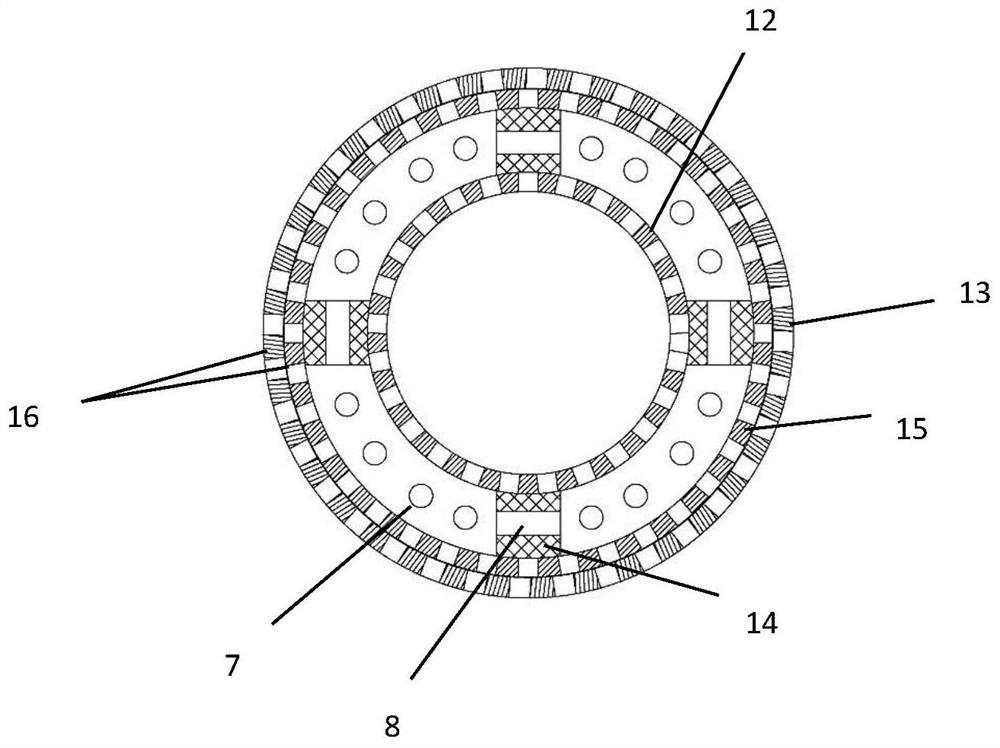

[0076] Embodiment 1 The frame type bone joint prosthesis provided by the present invention

[0077] The frame-type bone joint prosthesis provided in this embodiment is as follows: figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown, where figure 1 It is a split diagram of the structure of each layer of the frame bone joint prosthesis; figure 2 It is a schematic diagram of the shape and structure of the frame-type bone joint prosthesis; image 3 It is the A-A section view of the frame bone joint prosthesis; Figure 4 It is the B-B section view of the frame bone joint prosthesis; Figure 5 C-C sectional view of the frame-type bone joint prosthesis.

[0078]The material of the frame-type bone prosthesis in this embodiment can be prepared by using materials such as titanium alloy, tantalum metal, polylactic acid, PEEK material, etc. In this embodiment, it is preferably prepared by using titanium alloy material.

[0079] The frame-type bone joint prosthesis of...

Embodiment 2

[0097] Example 2 Formulation selection of hydrogel for promoting bone and joint regeneration

[0098] This example adopts the titanium alloy frame bone joint prosthesis provided in Example 1, and is divided into three groups according to different hydrogel formulations. The first group is the control group with pure GelMA hydrogel, and the second group is the control group using GelMA hydrogel. Hydrogel + osteogenic inducer group, the third group was the use of GelMA hydrogel + osteogenic induction + bone regeneration microenvironment additive group, in which GelMA hydrogel was 5% GelMA hydrogel, and the osteogenic inducer included 1 mg / ml of zoledronic acid, 100mmol / L of β-glycerophosphate, 10 - 3 mol / L dexamethasone, 500ug / ml vitamin C, bone regeneration supplements including 3mg / ml bone morphogenetic protein BMP-2, 30ug / ml fibroblast growth factor, 3ug / ml vascular endothelial growth factor, 30mg / ml of stem cell culture medium freeze-dried powder, and 0.5% LAP was used a...

Embodiment 3

[0099] Example 3 Selection of volume ratio of hydrogel and autologous bone fragments

[0100] This example adopts the titanium alloy frame type bone joint prosthesis provided in Example 1, and adopts the hydrogel formula provided in the third group of Example 2, wherein the volume ratio of hydrogel and autologous bone fragments is selected as 1:0, 1:1, 1:2, 1:3 and 1:4, to investigate the coverage effect of the gel preparation on the surface of the prosthesis with different volume ratios of hydrogel and autologous bone fragments. The results are shown in Table 1. The partial photos of the frame-type bone joint prosthesis covered with hydrogel when the volume ratios are 1:0 and 1:2, respectively, are shown in Fig. Figure 10 shown.

[0101] Table 1,

[0102]

[0103] When more autologous tissue is used, it can promote rapid regeneration and healing. It can be seen from Table 1 that when only hydrogel is contained, although the gel covers firmly and no voids remain, the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com