Regenerated cellulose filament for artificial ligament and application of regenerated cellulose filament

A technology for regenerating cellulose and artificial ligaments, which can be used in cellulose/protein conjugated man-made filaments, ligaments, tissue regeneration, etc., and can solve problems such as unfavorable growth of surrounding tissues, difficult cells, and excessively dense ligament weaving. Achieving favorable effects on cell migration and matrix formation, improving histocompatibility, and good histocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

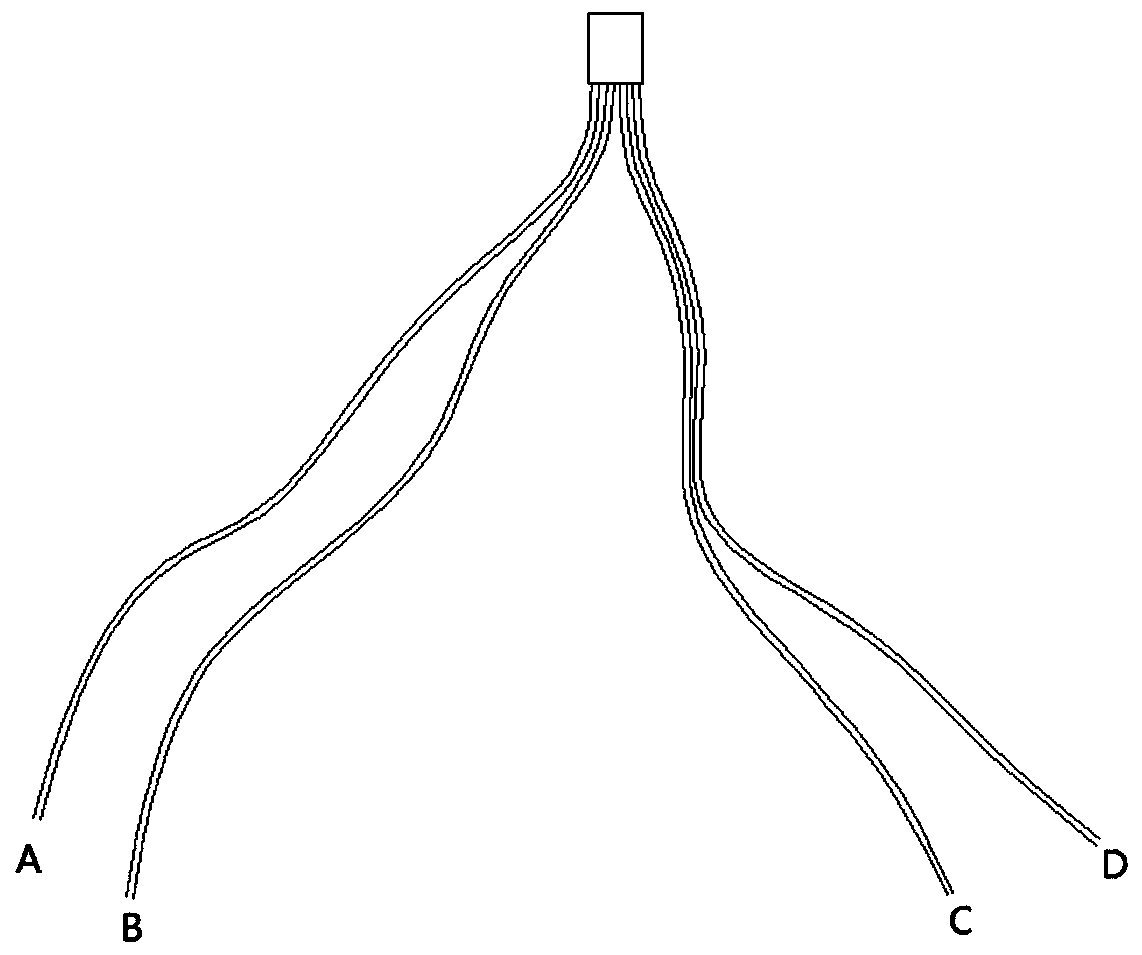

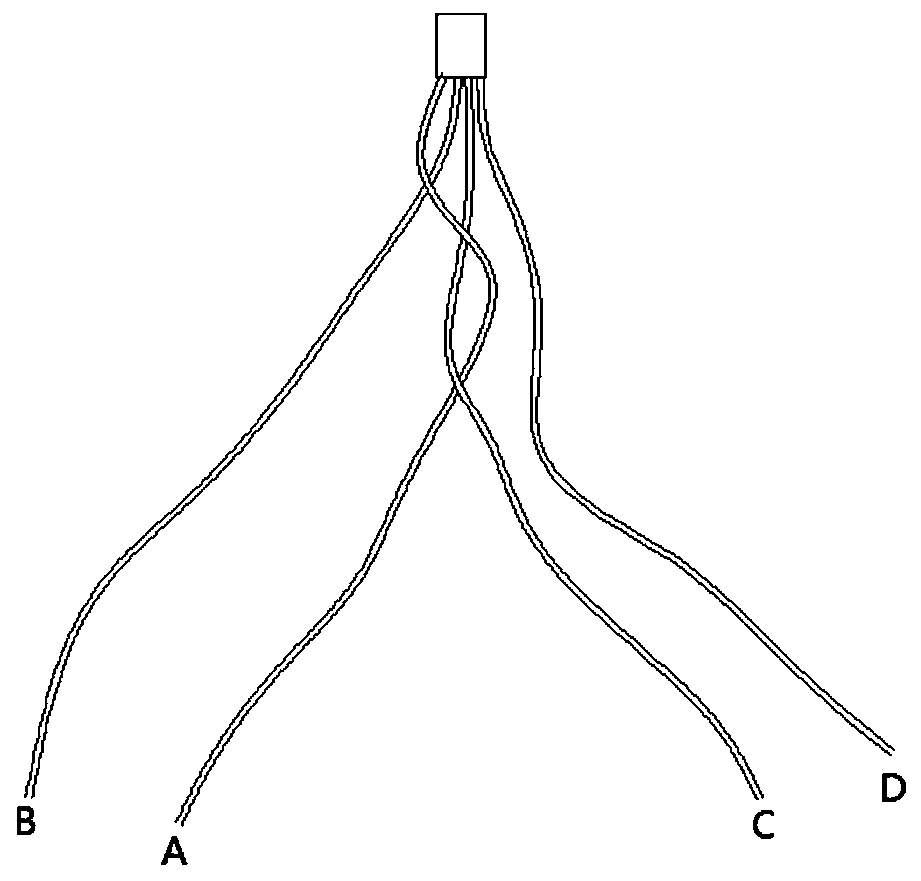

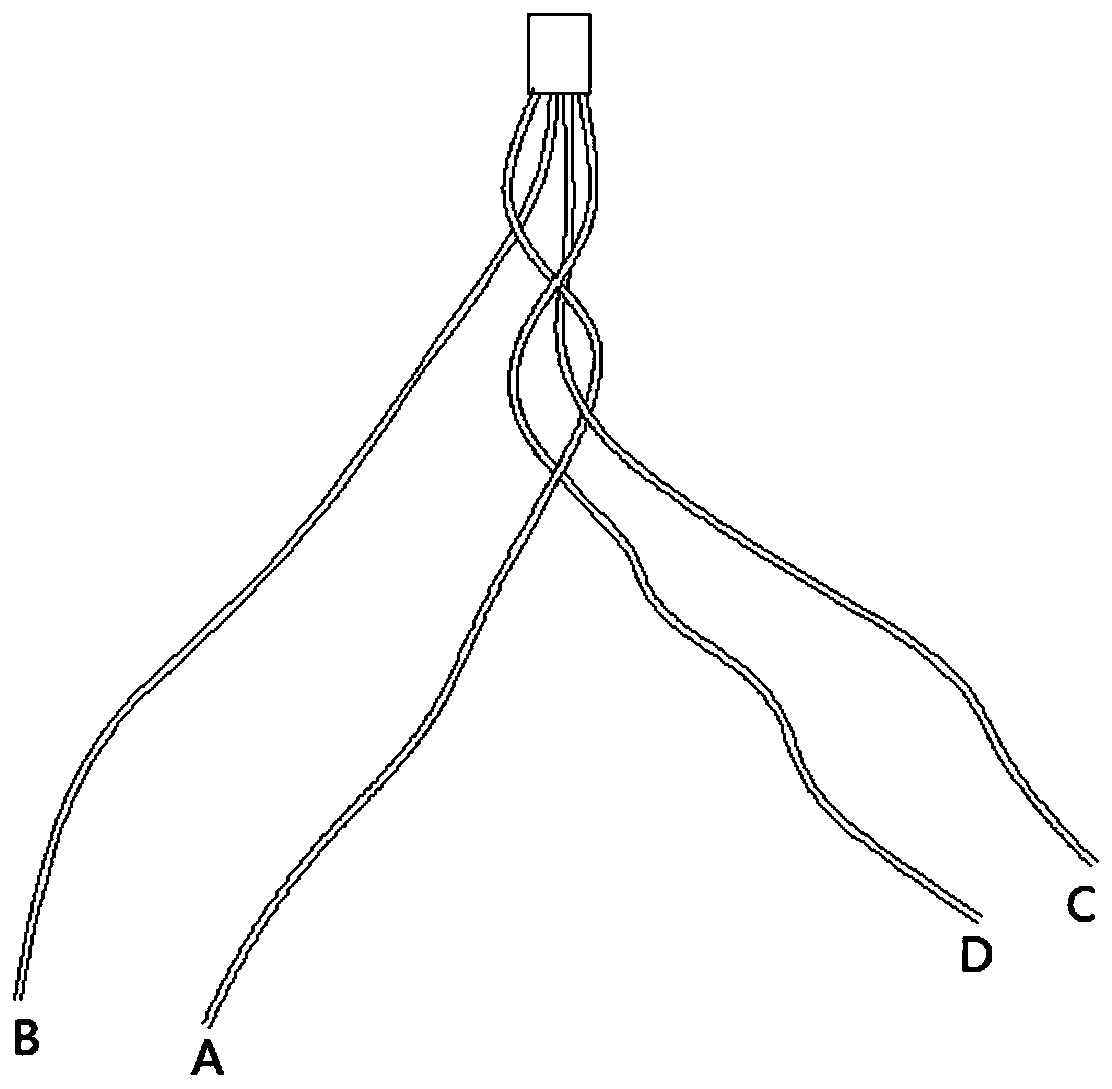

Image

Examples

Embodiment 1

[0028] Preparation of silk fibroin solution:

[0029] Put 200g silk at a temperature of 100°C and 4-6L Na with a mass concentration of 1g / L 2 CO 3 Degumming in the solution for 3 times, 30-40min each time, remove the sericin protein to obtain the degummed silk fibroin protein, then wash the obtained silk fibroin protein with deionized water, and dry it at 50-60°C to constant weight for later use .

[0030] Calcium chloride-ethanol-water (CaCl 2 -EtoH-H 2 O) solution, silk fibroin is dissolved in calcium chloride-ethanol-water (CaCl 2 -EtoH-H 2 (0) solution, dissolve the degummed silk fibroin in a constant temperature water bath at 60°C for 4-5h, after dissolving, after the silk fibroin solution is cooled to room temperature, use a centrifuge at 8 000-10000r / min, centrifuge for 5-10min, Obtain silk fibroin solution.

Embodiment 2

[0032] At room temperature, take 100ml 20% (mass volume fraction) silk fibroin protein solution, add 50g polyvinyl alcohol, 30mg chondroitin sulfate and stir until completely dissolved, then add 20g type I collagen and stir slowly until dissolved to form a spinning solution. Wet spinning technology is used to prepare regenerated fiber filaments. The spinning process is as follows: the spinning solution is squeezed into the spinneret through a pressure pump at a room temperature of 20-25°C; the spinning solution coming out of the spinneret enters the coagulation bath, the coagulation bath is 10% alcohol, and the length of the coagulation tank is 1m; Pressure 0.1MPa; spinning rate 5mL / h; winding rate 8r / min. Through the comparison of spinning process parameters, coagulation bath is the most influential factor, followed by spinning speed, and pressure is the least influential factor. Through water and alcohol coagulation bath experiments with different concentrations, when the c...

Embodiment 3

[0034] At room temperature, take 100ml 25% (mass volume fraction) silk fibroin protein solution, add 50g polyvinyl alcohol, 30mg chondroitin sulfate and stir until completely dissolved, then add 15g type I collagen and slowly stir until dissolved to form a spinning solution. Wet spinning technology is used to prepare regenerated fiber filaments. The spinning process is as follows: the spinning solution is squeezed into the spinneret through a pressure pump at a room temperature of 20-25°C; the spinning solution coming out of the spinneret enters the coagulation bath, the coagulation bath is 10% alcohol, and the length of the coagulation tank is 1m; Pressure 0.1MPa; spinning rate 5mL / h; winding rate 8r / min. The regenerated fiber filament prepared in this embodiment is named NF2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com