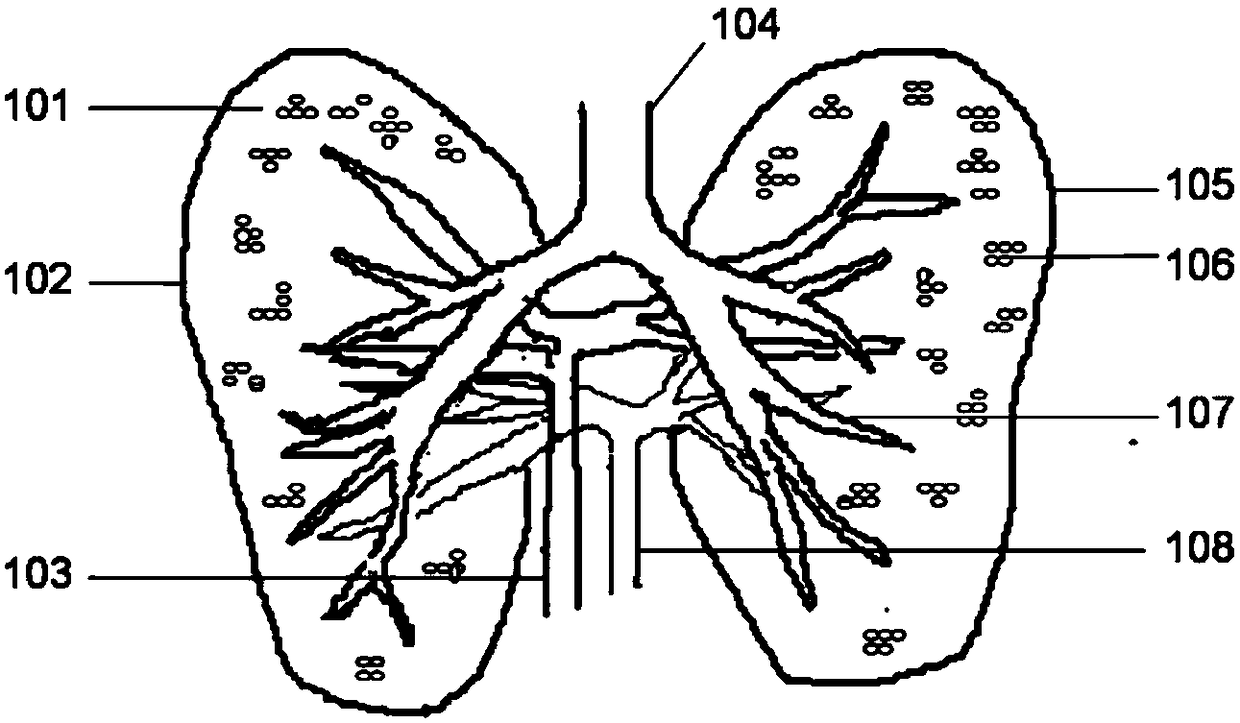

A kind of lung substitute and its three-dimensional printing and injection molding manufacturing method

A substitute, 3D printing technology, applied in the direction of biochemical equipment and methods, microorganisms, animal cells, etc., can solve the problems of long working hours, low forming efficiency, and inability to attach to the side surface of the formed body, so as to enhance viability and enhance Effects on suture resistance strength, improved composite efficiency, and physiological function of formed structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) 3D printing material preparation

[0036] Take 0.1g chitosan and 1g gelatin and place them in 100mL culture medium to dissolve them completely, and sterilize them to obtain chitosan-gelatin solution; prepare 0.05g / ml sodium superphosphate aqueous solution as chitosan cross-linking agent and cell Culture medium (DMEM medium); extract adipose-derived stem cells (ADSCs) and lung epithelial cells, culture and passage; mix adipose-derived stem cells (ADSCs) with chitosan-gelatin solution, wherein the concentration of adipose-derived stem cells is 1×10 5 each / mL; add 0.1% mass percentage of endothelial growth factor and epithelial growth factor to the fat stem cell-chitosan-gelatin solution; the mass volume concentration obtained by dissolving degradable polyurethane in tetraethylene glycol is 2% Synthetic polymer solution, sterilized for use.

[0037] 2) Preparation of lung epithelial cell microspheres

[0038] Mix the lung epithelial cells and the sodium alginate aqueo...

Embodiment 2

[0046] 1) 3D printing material preparation

[0047] Take 1g of sodium alginate and 20g of gelatin in 100mL of culture medium to dissolve them completely, and sterilize to obtain a sodium alginate-gelatin solution; prepare 1g / ml of calcium chloride aqueous solution as a sodium alginate cross-linking agent and cell culture medium (DMEM culture medium); bone marrow stem cells and lung epithelial cells were extracted, cultured and passaged; bone marrow stem cells were mixed with sodium alginate‐gelatin solution, and the concentration of bone marrow stem cells was 3×10 4 each / mL; bone marrow stem cells-sodium alginate-gelatin solution was added with 0.1% mass percentage of endothelial cell growth factor and cell transfer factor, platelet factor mixture and epithelial cell growth factor; the degradable polycaprolactone was dissolved in four A synthetic polymer solution with a mass volume concentration of 2% was obtained in ethylene glycol, and was sterilized for use.

[0048] 2) Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com