Multi-channel riser reaction device and application thereof

A technology of a reaction device and a riser, applied in the field of a multi-channel riser reaction device, can solve the problems of reducing the selectivity and yield of the target product, inconsistent particle retention, reducing the average conversion rate of the solid outlet, etc., so as to avoid deep oxidation to COX , good heat transfer function, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

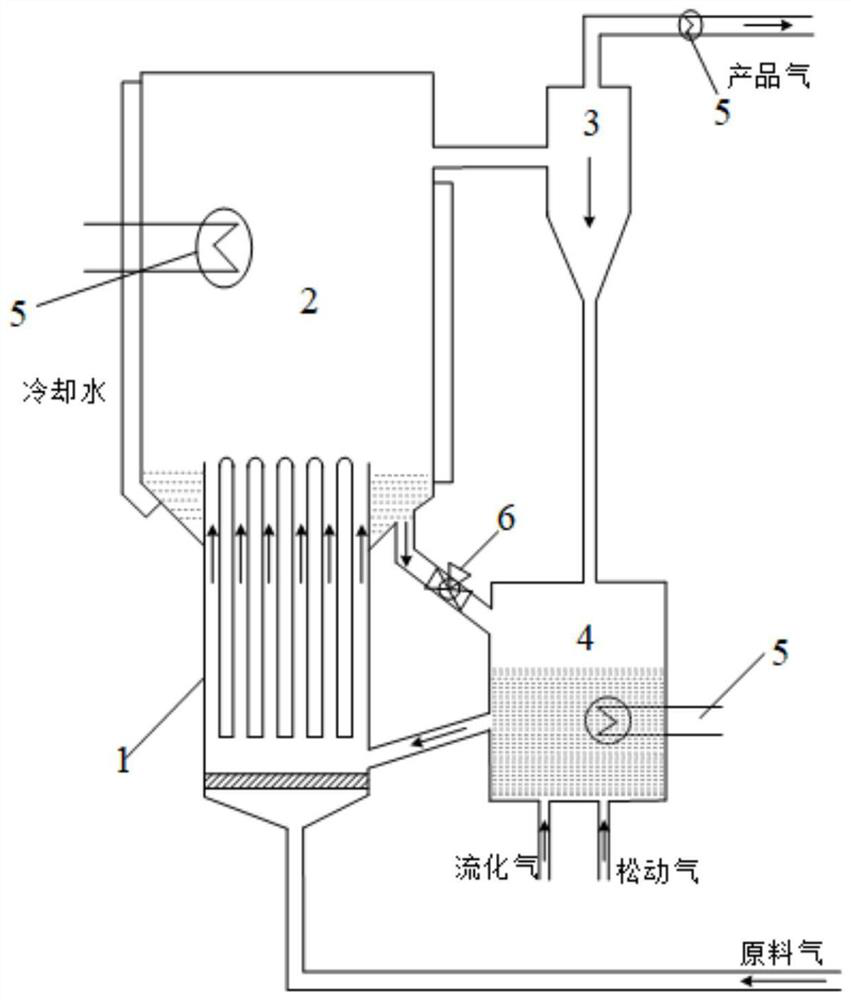

[0069] This embodiment provides a multi-channel riser reaction device, such as figure 1 As shown, the reaction device includes six riser reactors 1 , a settling device 2 , a gas-solid separation device 3 and a material returning device 4 .

[0070] The riser reactors 1 are arranged in parallel, and heat transfer is performed between adjacent riser reactors 1 .

[0071] The upper part of the riser reactor 1 is connected to the bottom of the settling device 2 , and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling device 2 .

[0072] The bottom of the riser reactor 1 is connected to the discharge port of the material returning device 4 .

[0073] The bottom of the riser reactor 1 is provided with a feed gas inlet pipeline.

[0074] The discharge port of the settling device 2 is connected to the material returning device 4 .

[0075] The settling device 2 is provided with a heat exchange device 5 .

[0076] The gas-solid separa...

Embodiment 2

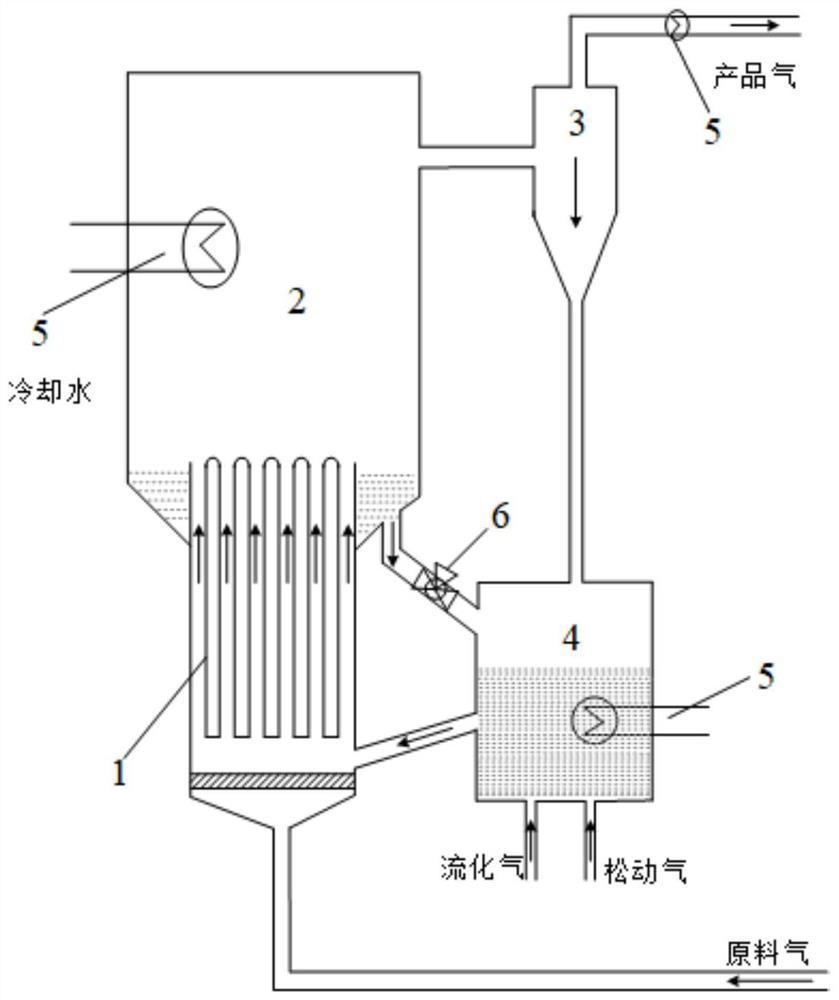

[0082] This embodiment provides a multi-channel riser reaction device, such as figure 2 As shown, the reaction device includes six riser reactors 1 , a settling device 2 , a gas-solid separation device 3 and a material returning device 4 .

[0083] The riser reactors 1 are arranged in parallel, and heat transfer is performed between adjacent riser reactors 1 .

[0084] The upper part of the riser reactor 1 is connected to the bottom of the settling device 2 , and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling device 2 .

[0085] The bottom of the riser reactor 1 is connected to the discharge port of the material returning device 4 .

[0086] The bottom of the riser reactor 1 is provided with a feed gas inlet pipeline.

[0087] The discharge port of the settling device 2 is connected to the material returning device 4 .

[0088] The settling device 2 is provided with a heat exchange device 5 .

[0089] The gas-solid separ...

Embodiment 3

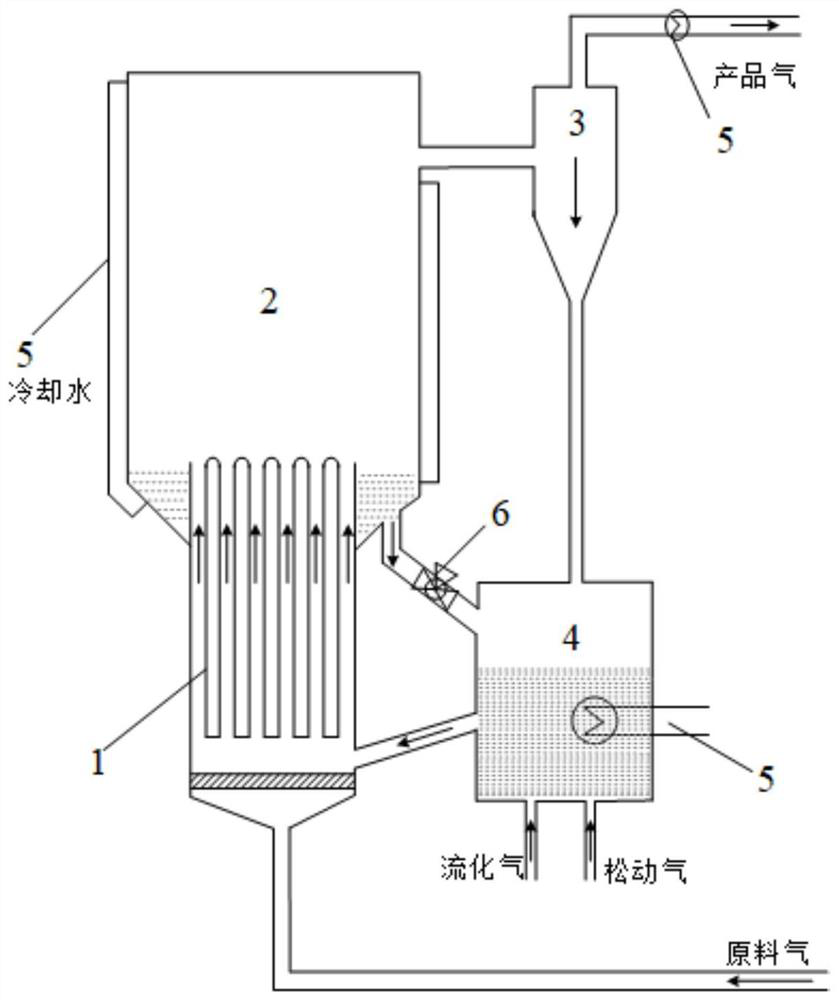

[0095] This embodiment provides a multi-channel riser reaction device, such as image 3 As shown, the reaction device includes six riser reactors 1 , a settling device 2 , a gas-solid separation device 3 and a material returning device 4 .

[0096] The riser reactors 1 are arranged in parallel, and heat transfer is performed between adjacent riser reactors 1 .

[0097] The upper part of the riser reactor 1 is connected to the bottom of the settling device 2 , and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling device 2 .

[0098] The bottom of the riser reactor 1 is connected to the discharge port of the material returning device 4 .

[0099] The bottom of the riser reactor 1 is provided with a feed gas inlet pipeline.

[0100] The discharge port of the settling device 2 is connected to the material returning device 4 .

[0101] The settling device 2 is provided with a heat exchange device 5 .

[0102] The gas-solid separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com