Microbial kitchen waste treatment machine and working method

A processing machine and microbial technology, which is applied in the field of microbial kitchen waste processing machines, can solve problems such as odor emission, residents' reluctance to use it close to it, garbage bins that cannot be used for advanced treatment of kitchen waste, and achieve the goal of improving the willingness to use and resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

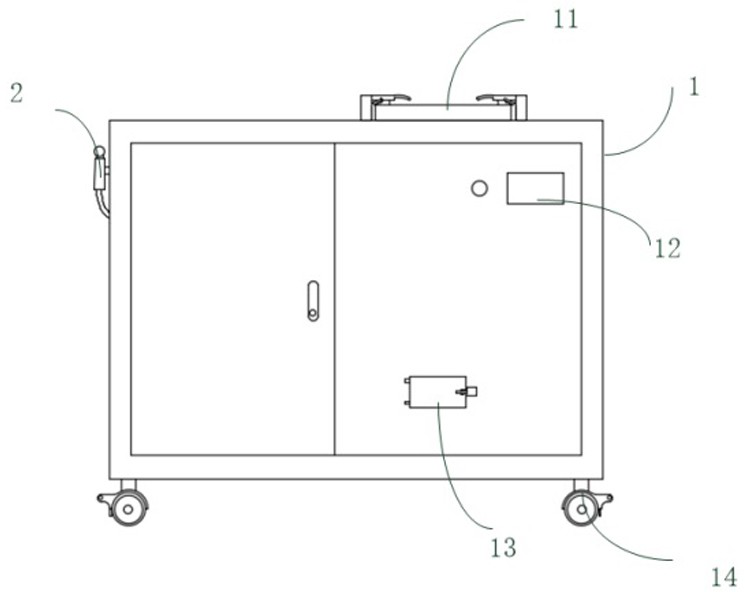

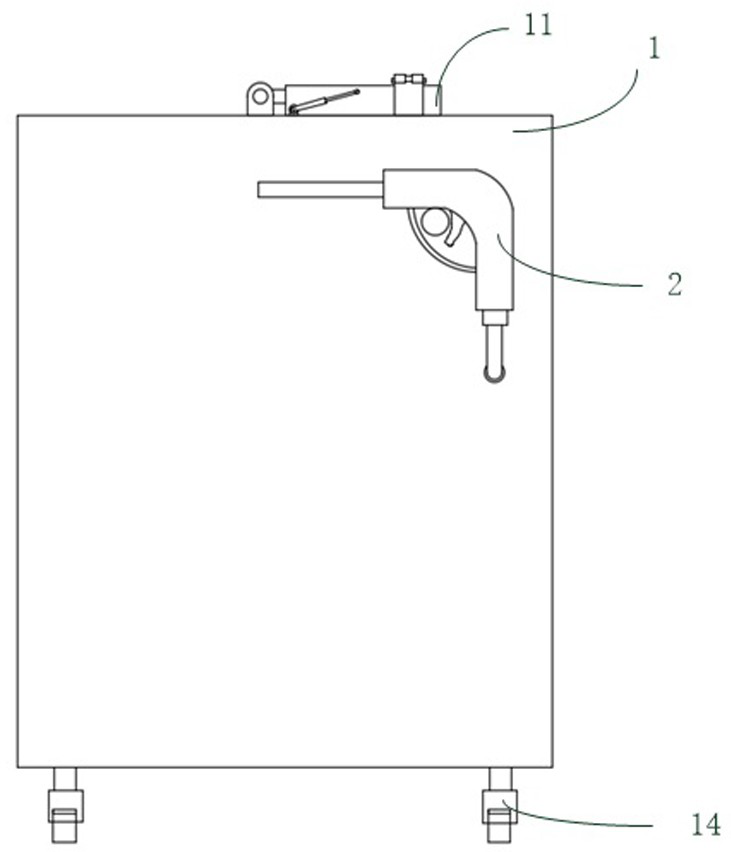

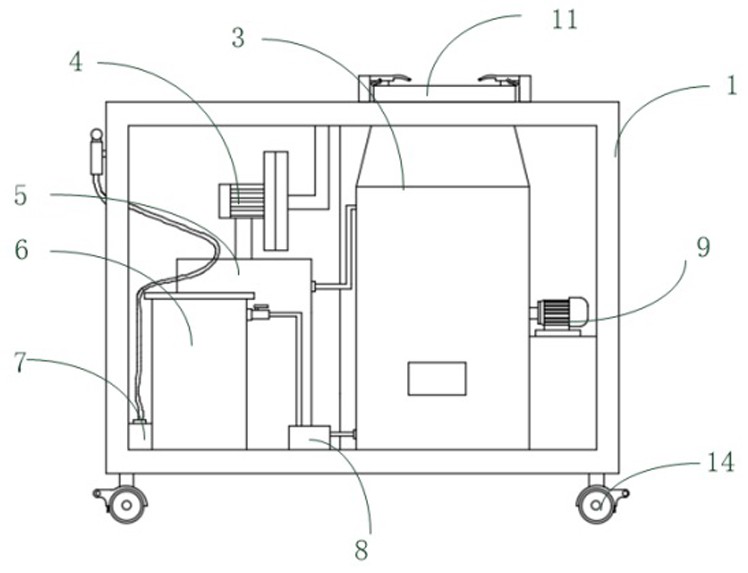

[0029] Such as Figure 1-4 As shown, a microbial food waste treatment machine includes a cabinet body 1, a control panel is arranged on the upper part of the cabinet body 1, and a crushing mechanism, a biological deodorization mechanism and a solid-liquid separation mechanism are arranged in the cabinet body 1. The cabinet body 1 is respectively provided with a feed port and a discharge port connected with the crushing mechanism, a cover plate 11 is rotatably arranged above the feed port, and a sealing plate 13 is rotatably provided on the discharge port, The bottom of the cabinet body 1 is provided with sliding wheels 14 . The crushing mechanism is respectively connected with the biological deodorization mechanism and the solid-liquid separation mechanism, the solid-liquid separation mechanism is provided with a cleaning mechanism and the cleaning mechanism is connected with the solid-liquid separation mechanism, the The crushing mechanism, the biological deodorization mecha...

Embodiment 2

[0037] A working method of a microbial food waste processor, comprising the following steps:

[0038] S1. First pour the kitchen waste into the crushing box, then add fermented bacteria powder into the crushing box, add probiotic powder into the biodegradation box, clean the feed port with a cleaning spray gun, and then close the cover. Press the button on the control panel to control and start the crushing auger in the crushing box to crush the meal waste;

[0039] S2. During the crushing process of meal waste, the suction pump starts at the same time, and the suction pump sucks the air containing odor molecules in the crushing box into the biodegradation box, and uses the enzyme secreted by the probiotics in the biodegradation box to decompose the air ammonia and hydrogen sulfide to deodorize the drawn air, and the deodorized air is discharged through the exhaust pipe;

[0040] S3. During the crushing process of food waste, the water pump starts at the same time, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com