Super-long collision avoidance control method for double-altitude three-row roller way

A control method and high-line technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as waste of billet raw materials, production rhythm and abnormal production, red steel material collision deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

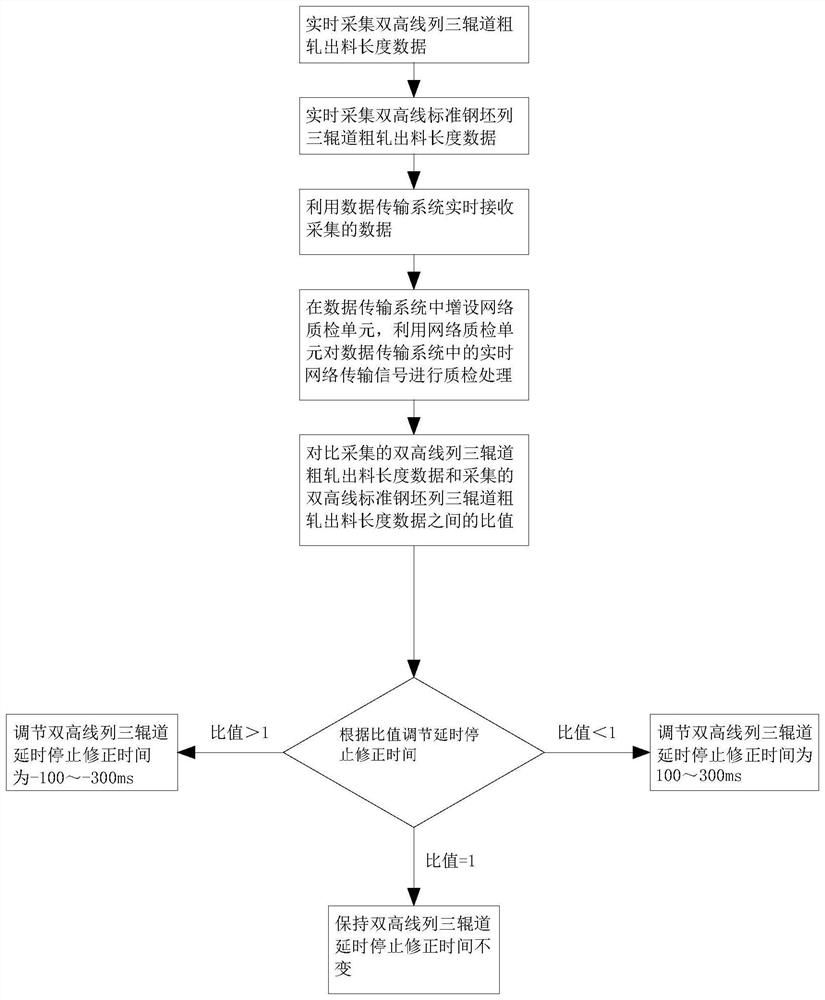

[0063] according to figure 1 , 3 As shown, this implementation provides a super-long collision avoidance control method with double-high lines and three-roller tables, including the following steps:

[0064] Step 1: Real-time collection of data on the discharge length of rough rolling on double-high lines and three-roller tables, wherein the data on the discharge length of rough rolling on double-high lines and three-roller tables and the standard steel billet on double-high lines are collected in real time at a certain time interval t each time List the discharge length data of the three-roller rough rolling, and the time interval t is 50ms;

[0065] Step 2: Collect the discharge length data of the three-roller table rough rolling of the double-high line standard billet row in real time. The standard billet lists the discharge length data of three-roller rough rolling, and the time interval t is 50ms;

[0066] Step 3: Use the data transmission system to receive in real tim...

Embodiment 2

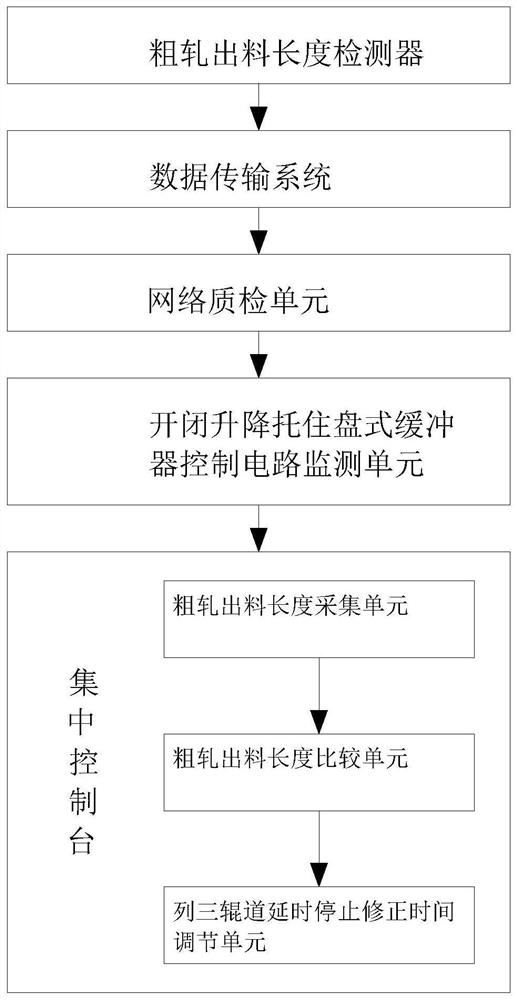

[0079] according to figure 2 As shown, this embodiment proposes a super-long collision avoidance control system with double-high lines and three-roller tables, including a rough rolling discharge length detector, a data transmission system, a network quality inspection unit, and a connection with the rough rolling discharge length detector The centralized control console includes a rough rolling discharge length acquisition unit, a rough rolling discharge length comparison unit and a row three roller table delay stop correction time adjustment unit;

[0080] The rough rolling discharge length detector is used to detect the rough rolling discharge length of double-high line row three-roller table and the double-high line standard billet row three-roller table rough rolling discharge length;

[0081] The data transmission system is used to receive in real time the data on the length of the rough rolling of the double-high line and the three-roller table and the length data of t...

Embodiment 3

[0091] A storage medium having stored thereon a plurality of instructions adapted to be loaded and executed by a processor:

[0092] Real-time collection of the rough rolling discharge length detected by the double-high line row three-roller table rough rolling discharge length and the double-high line standard billet row three-roller table rough rolling discharge length detected by the rough rolling discharge length detector;

[0093] The data transmission system receives and collects the data of the length of the rough rolling of the double-high line and the three-roller table in real time and the data of the length of the rough-rolling of the double-high line standard billet and the three-roller table;

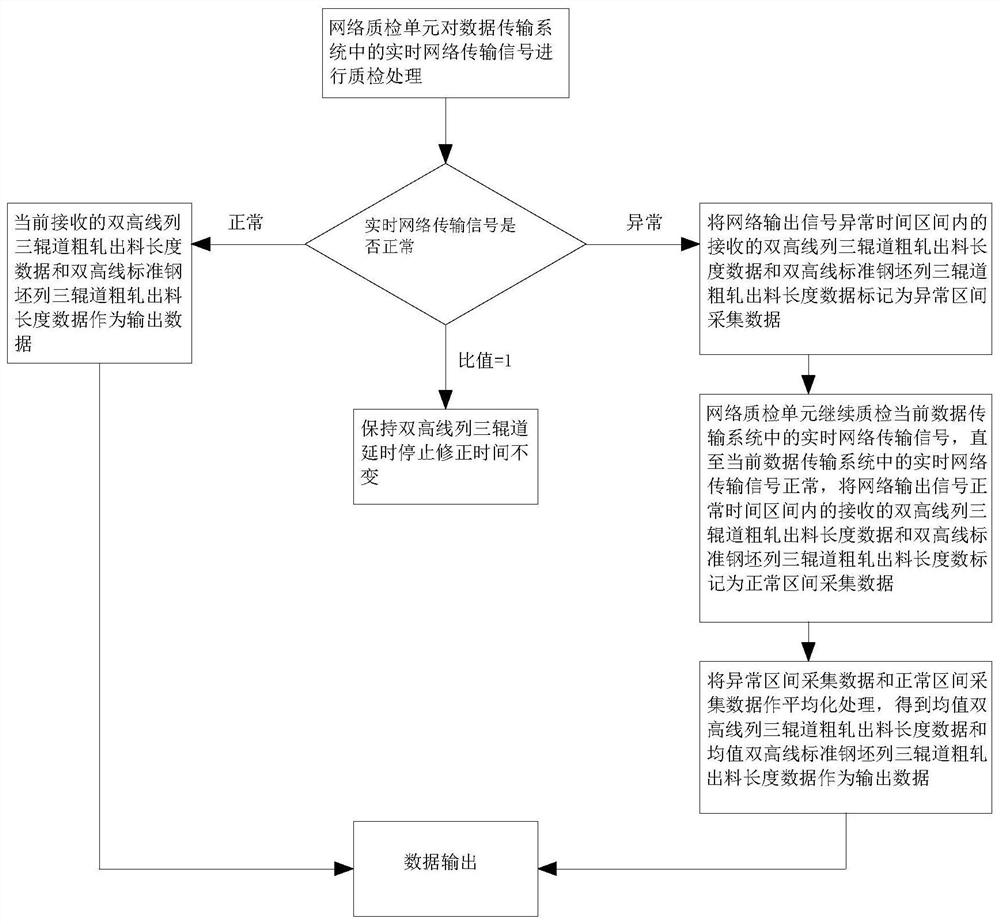

[0094] A network quality inspection unit is added to the data transmission system, and the network quality inspection unit is used to perform quality inspection processing on the real-time network transmission signals in the data transmission system;

[0095] Comparing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com