Automatic kitchen knife blank welding machine

An automatic welding machine, kitchen knife technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of unstable quality, large physical injury to welders, low efficiency, etc., to achieve high welding quality, improve market competitiveness, High welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

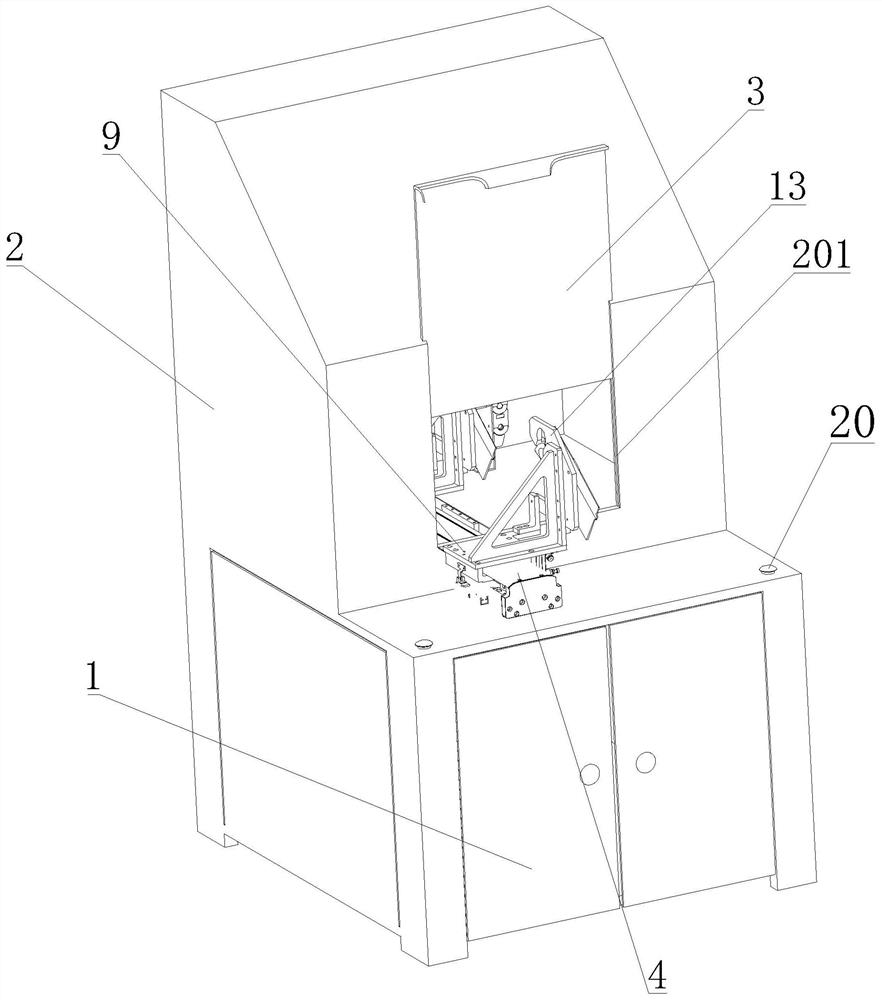

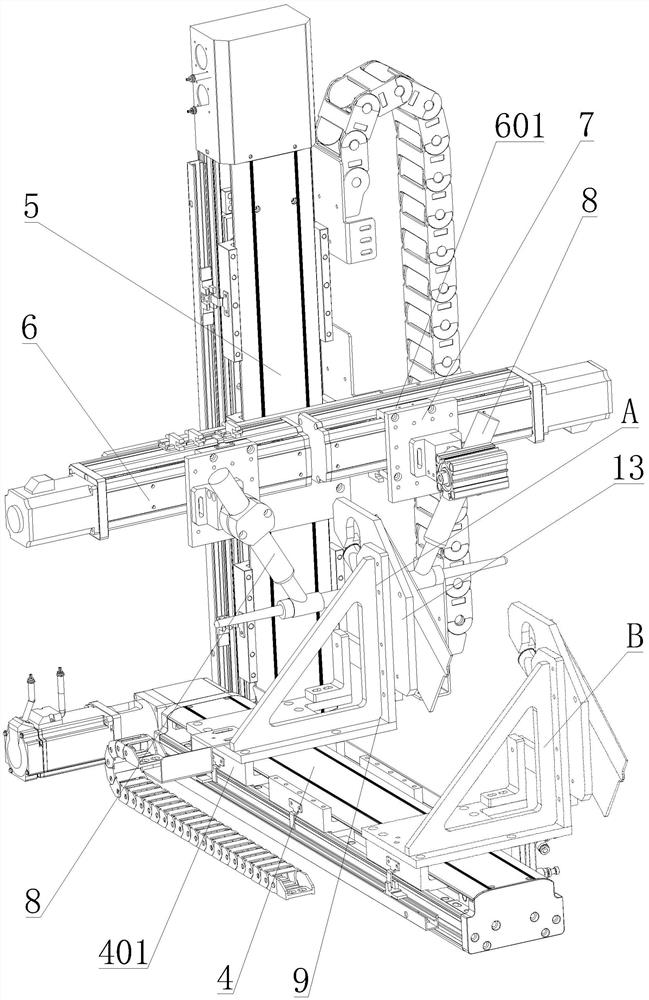

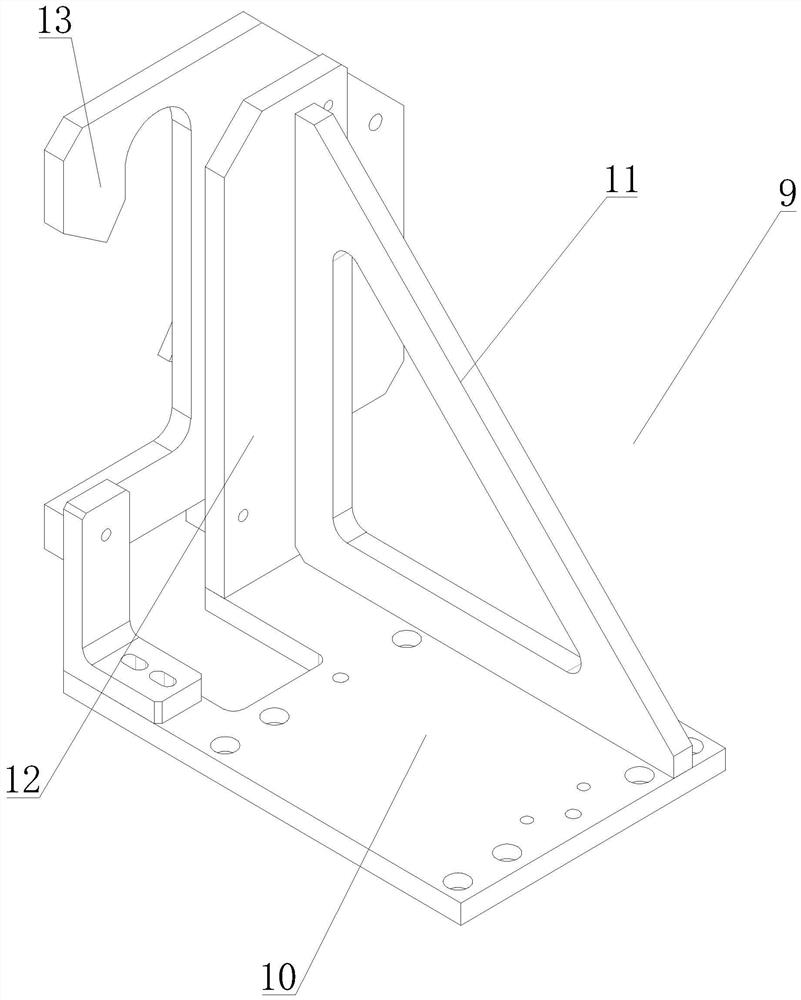

[0022] like Figure 1-5 Shown, the present invention provides a proposed chopper blade embryos automatic welding machines, comprising a host placed cabinet 1, the housing 2, the protective door 3, X-axis linear module 4, Z-axis linear module 5, Y-axis linear module 6 , the mounting bracket 9 and a switch 20; host cabinet is placed within a control system is provided with a PLC and welding the host; the casing 2 is provided in the host computer 1 is placed on the cabinet, the housing 2 is provided with a longitudinal side of the opening 201; protective door 3 slidably disposed the cabinet 2, 3 located in the opening protective door 201, 3, when the protection door can be closed for welding tool embryos by providing protection door 3, staff play a very good protection; X-axis linear module 4 is provided host placed on the cabinet 1, X-axis linear module 4 is located within the housing 2, X-axis linear module 4 through the longitudinal opening 201, X-axis linear module 4 comprises a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com