Molding machine with closed hydraulic drive system

A drive system and molding machine technology, applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., to achieve high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

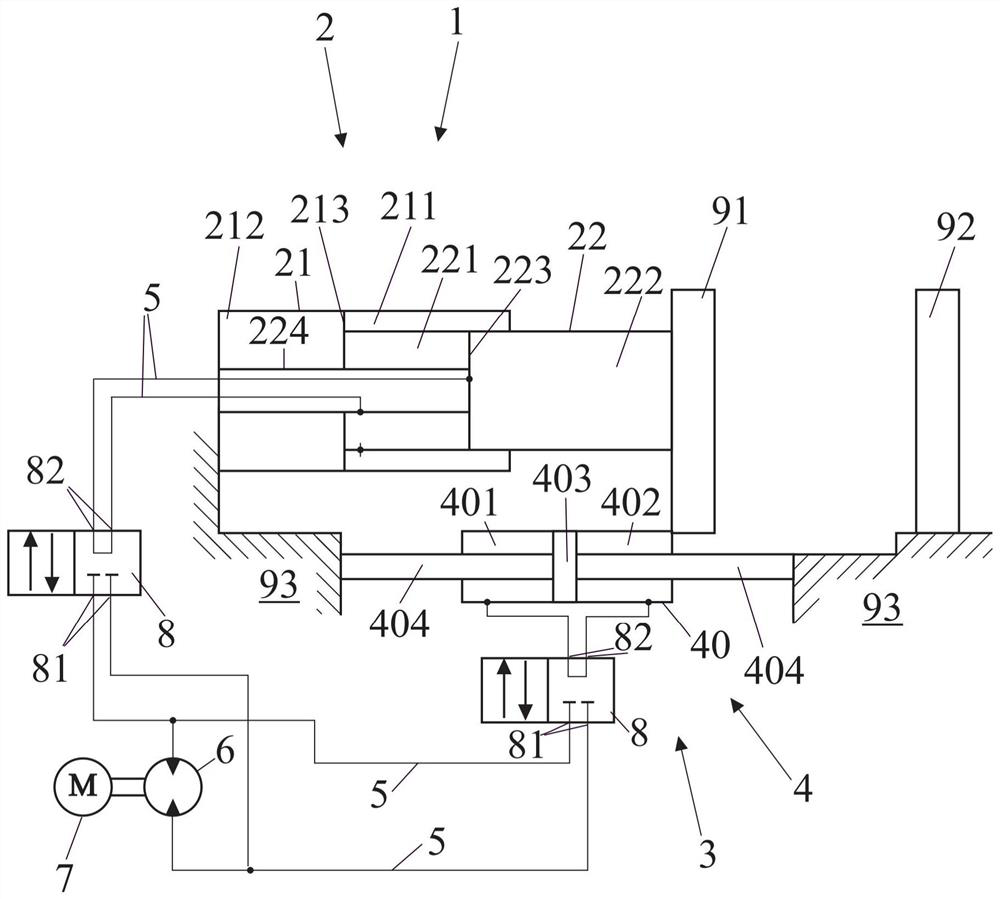

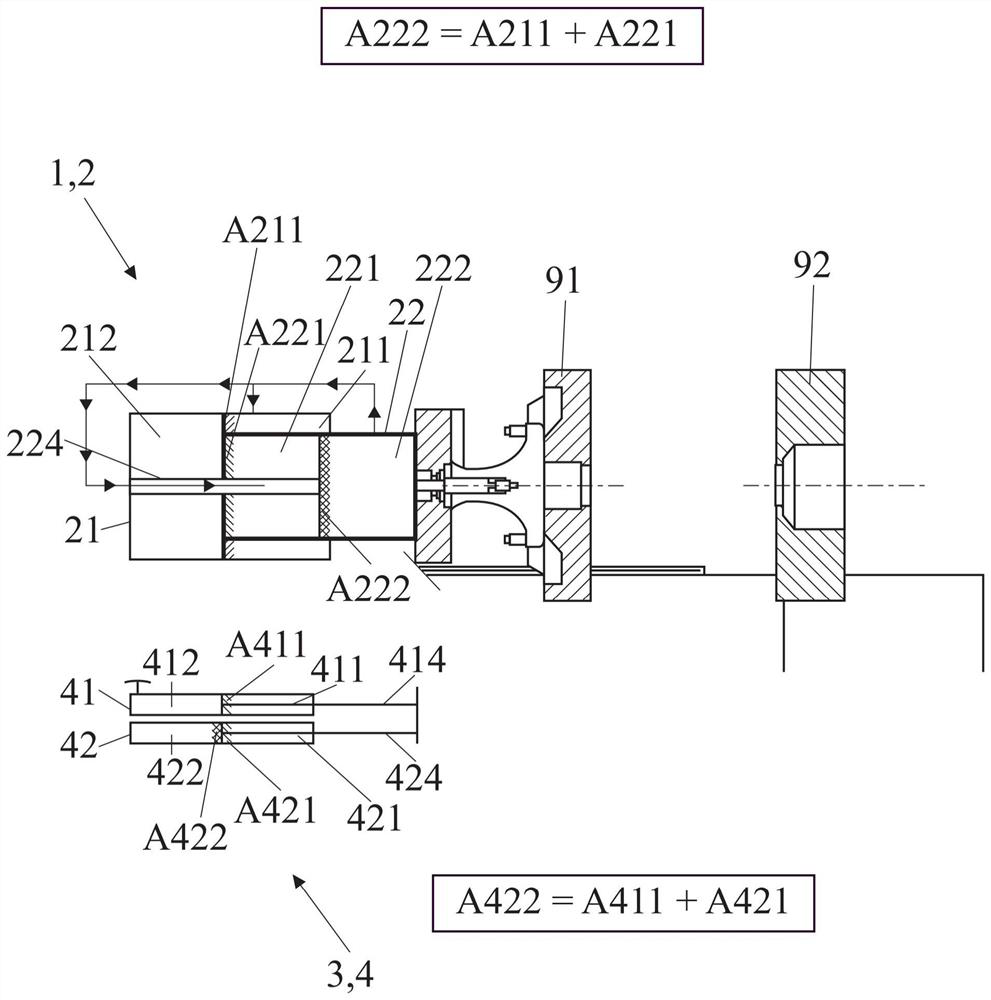

[0135] figure 1 A schematic diagram of a closed hydraulic system is shown, which includes the actuator 2 of the mold clamping force device 1 and the actuator 4 of the quick stroke device 3 for applying force to the movable mold clamping plate 91 . Also shown are the fixed mold clamping plates 92 and the machine frame 93 of the forming machine 9 . The two actuators 2 , 4 are driven with hydraulic fluid via a hydraulic line 5 by a pump 6 driven by an electric motor 7 . The hydraulic drive can also have several pumps 6 and / or several electric motors 7 .

[0136] In this case, a switching element 8 is arranged between the pump 6 and the actuator 2 of the clamping force device 1 and the pump 6 and the actuator 4 of the rapid stroke device 3 . The switching element 8 can be formed as a 2-port / 2-way valve (2-Port / 2-Wege-Ventil), thus having two connections 81 on the side of the pump 6 and two connections on the side of the actuators 2, 4 82. Furthermore, the two switching element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com