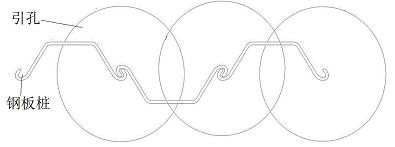

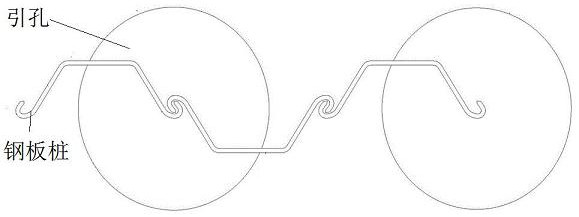

Steel pile casing positioning device and method for steel sheet pile hole guiding construction

A technology of positioning device and steel casing, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor positioning ability of steel casing, difficulty in inserting and driving steel sheet piles, and not being on the same plane, and achieve the goal of supporting equipment Less, meet the needs of special geological conditions, and easy to accept the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

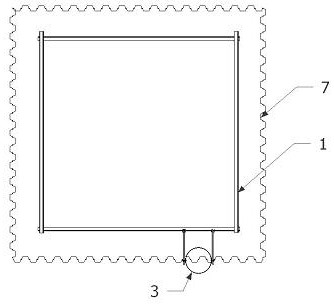

[0039] like image 3 and Figure 4 As shown, this embodiment is a steel casing positioning device for steel sheet pile lead hole construction, including positioning guide frame 1, steel pipe positioning pile 2, steel casing 3, anchor pin device 4, positioning buckle 5 and steel sheet pile insertion slot Frame 6.

[0040] like Figure 5 As shown, the positioning guide frame 1 is fixed on the positioning pile 2 by welding the fixed steel plate.

[0041] like Image 6 As shown, the steel casing 3 of this embodiment is connected to the positioning buckle 5 through the fixing rod 41 of the anchor pin device 4 . The positioning buckle 5 is installed on the positioning guide frame 1, that is, it is fixed on the I-beam 11 of the positioning guide frame, and the positioning buckle 5 is realized by the tightness of the top elastic knob handle 51 and the side elastic knob handle 55. The stepless adjustment of the horizontal position on the beam 11; the outer side of the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com