A Conformal Diffuser Combining Radial and Axial Diffusers

A diffuser, axial technology, applied in the direction of machines/engines, pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problem that the diffuser cannot have too long radial blades and the application range is limited Limitation and other problems, to achieve the effect of suppressing flow separation, ensuring continuity and increasing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail and concretely below through specific embodiments, so as to make the present invention better understood, but the following embodiments do not limit the scope of the present invention.

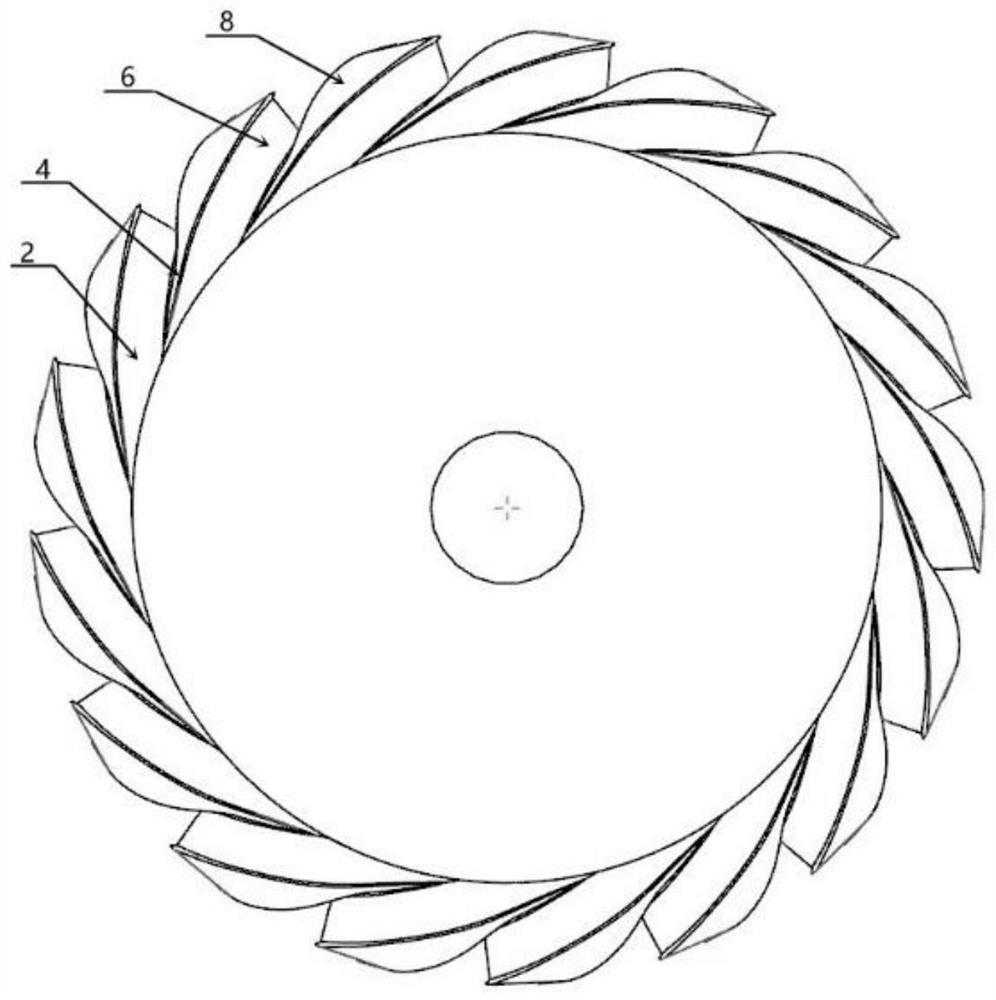

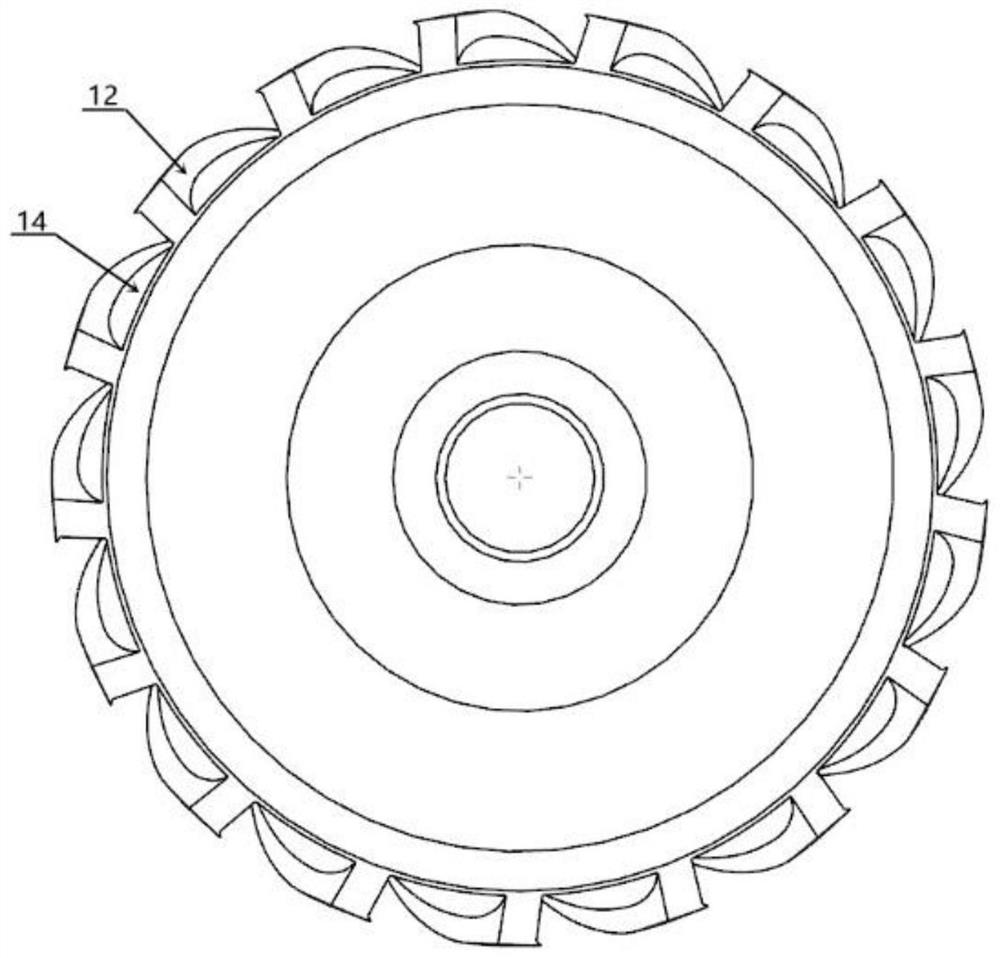

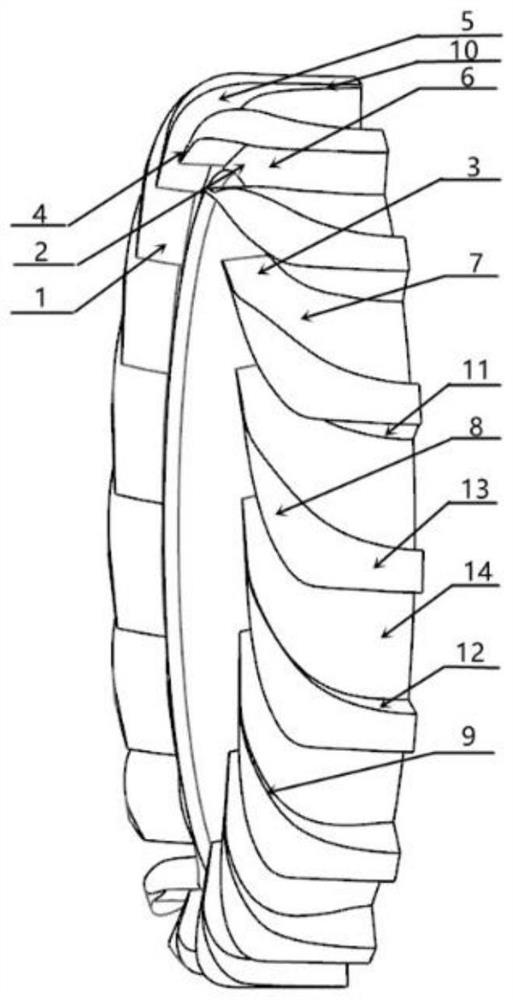

[0027] like Figure 1 to Figure 8 As shown, a radial and axial diffuser of the present invention is a centrifugal compressor conformal diffuser structure, the conformal diffuser includes an inner casing and blades; The structure is complex and the size is small, so 3D printing is recommended. The diffuser vanes are evenly distributed along the circumferential direction of the diffuser according to the required number, and the airflow passage in the diffuser is formed between the two adjacent vanes. Each diffuser vane includes a radial segment, a turning segment and an axial segment integrally constructed. The front end of the radial section of the diffuser vane is wedge-shaped, the thickness of the vane is small, and the leading edge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com