Offset type starting vector sealing valve

A biased, vector technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problem of failure to achieve point break, point repair, interruption or paralysis of pipeline network trunk system, loss of resources such as material resources and media and other problems, to achieve the effect of compact structure, easy processing, and reduced assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

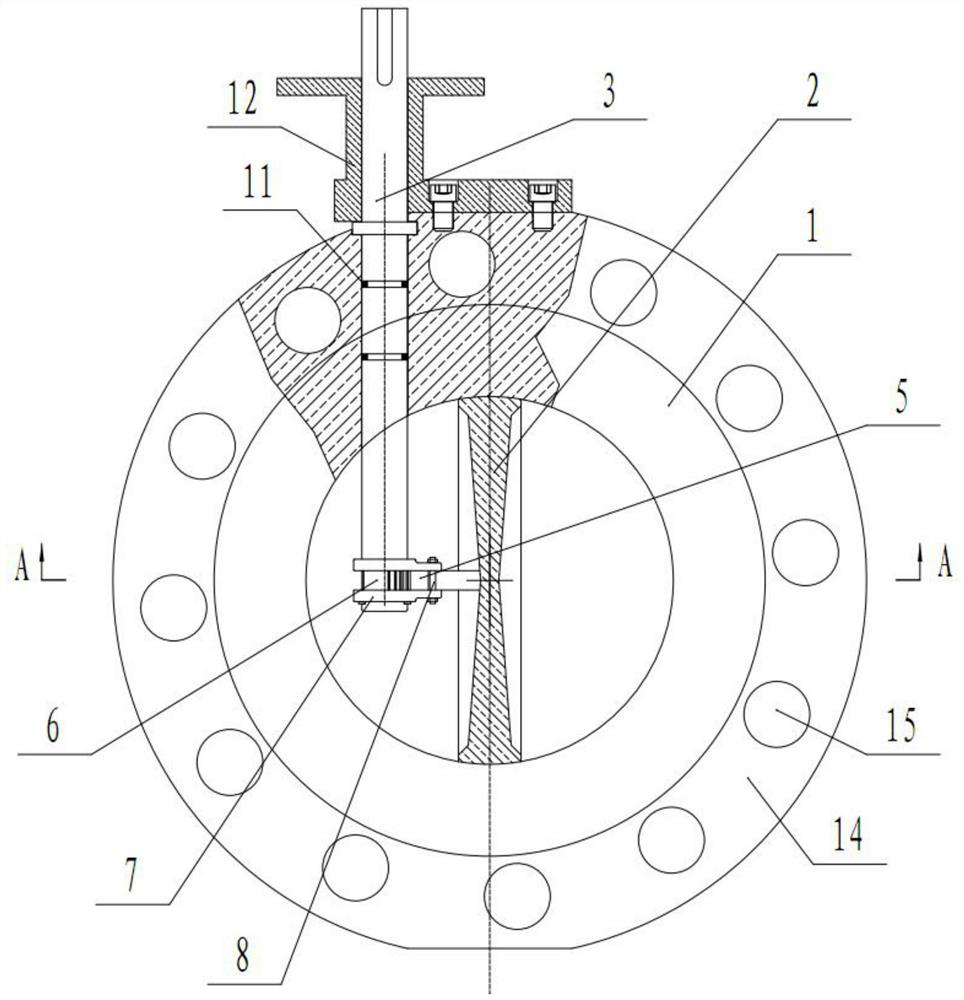

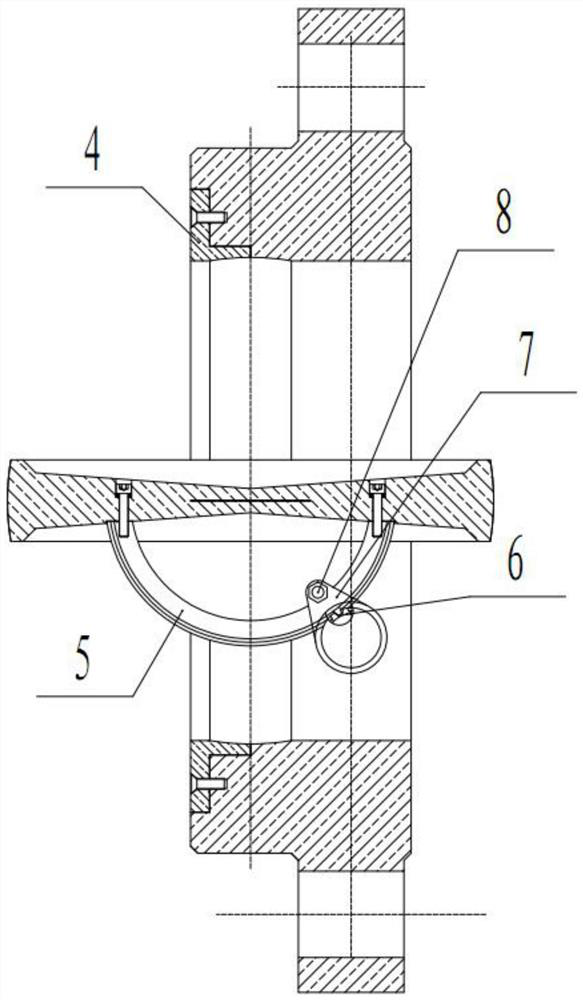

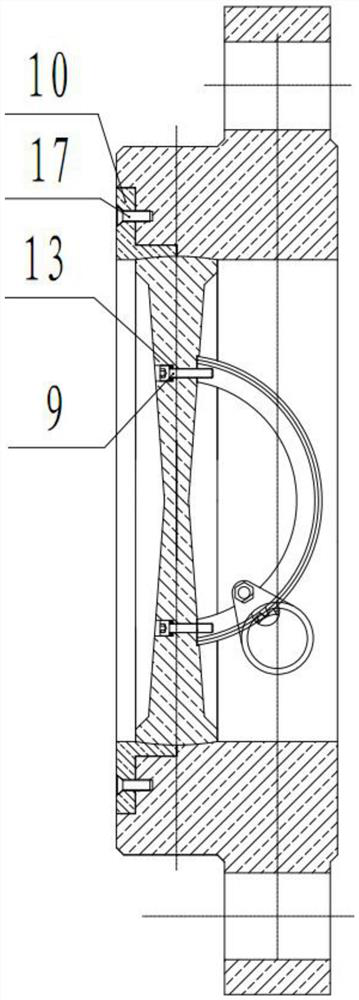

[0036] Embodiment 1: as Figure 1-8 As shown, a biased starting vector seal valve includes a valve body 1, a valve plate 2 and a valve shaft 3, the valve plate 2 is rotatably connected to the valve body 1, and the axial half of the valve body 1 is set It is a hemispherical cavity, and the other half of the inner cavity is a cylindrical cavity. The vector sealing ring 4 is embedded in the cylindrical cavity. The inner surface of the vector sealing ring 4 and the hemispherical cavity of the valve body 1 form a spherical section cavity. The cross-section cavity is the same, the center symmetry of one side of the valve plate 2 is axially fixedly connected with a sector gear 5, and the driving gear 6 meshing with the sector gear 5 is fixedly connected to the valve shaft 3, and the valve shaft 3 is rotatably connected to the valve body 1 and is biased. Set a distance from the center of the valve plate 2 (the axis of the valve shaft intersects with the axis of the valve plate or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com