Heat preservation sleeve for heat insulation of heating pipeline

A thermal insulation cover and thermal insulation cover technology, applied in pipeline protection, thermal insulation, household heating, etc., can solve the problems of poor thermal insulation effect, limited thermal insulation effect, inability to store solar heat and heat, etc., and achieve heat transfer and thermal insulation , the effect of preventing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

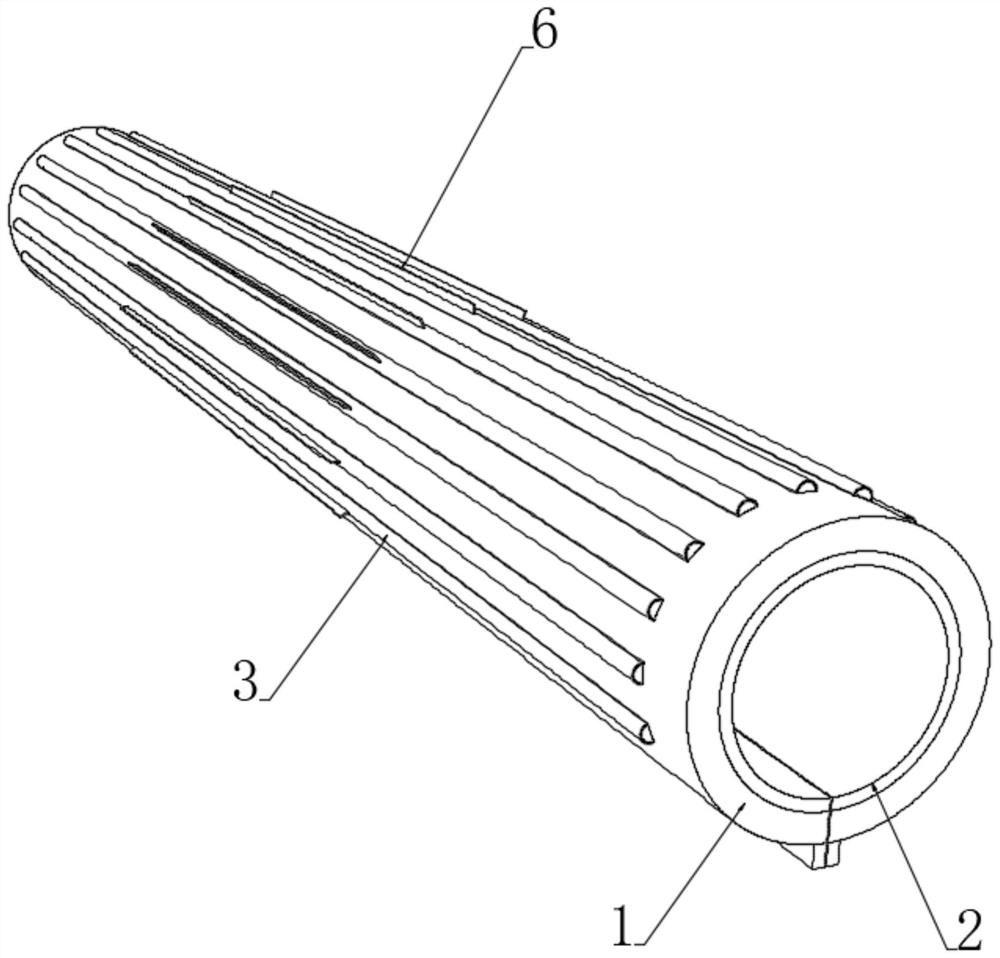

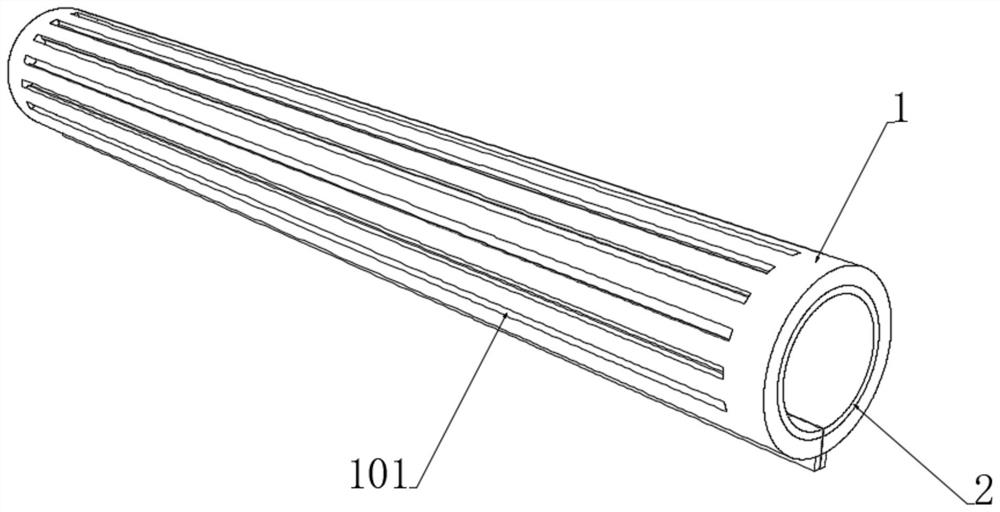

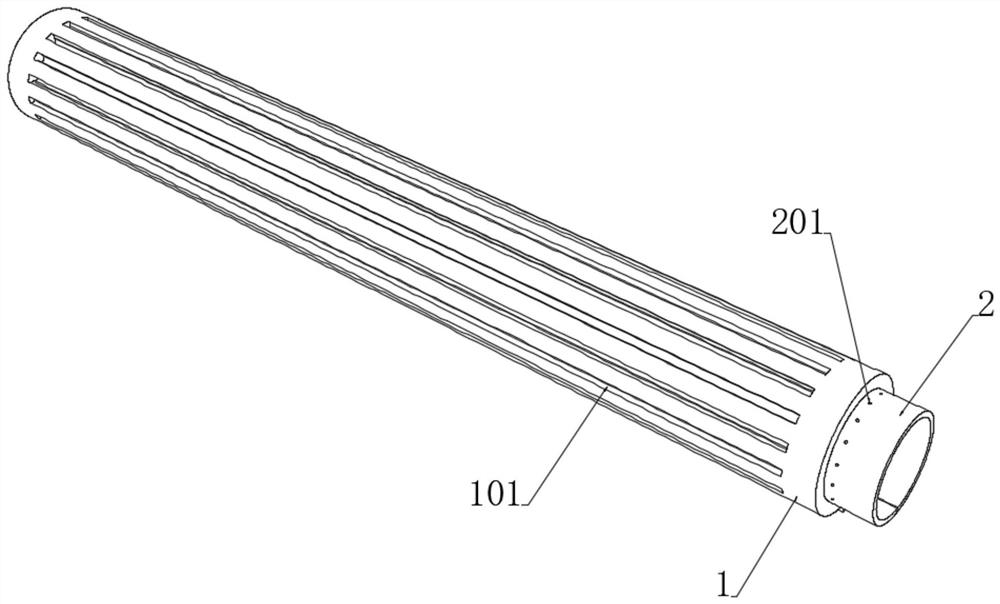

[0044] seefigure 1 , a thermal insulation cover for heating pipes, comprising an inner heat-conducting cover 2 and an outer heat-insulating cover 1, the outer heat-insulating cover 1 is made of heat-insulating rubber and plastic material, and the inner heat-conducting cover 2 is made of flexible heat-conducting material One end of the outer heat insulation sleeve 1 and the inner heat conduction sleeve 2 are provided with a docking interface, and the outer end wall of the outer heat insulation sleeve 1 is provided with a mounting strip corresponding to the interface position, and the outer heat insulation sleeve 1 and the inner heat conduction sleeve 2 are both flexible and have an interface, which makes it easy to flexibly set the outer heat insulation sleeve 1 and the inner heat conduction sleeve 2 on the heating pipe. After the installation is completed, a pair of installation strips can be locked by using the installation screws in the prior art .

[0045] see Figure 2-6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com