An impregnation basket and an impregnation basket automatic feeding system for dipping and deliquoring cores

An automatic feeding and core wrapping technology, which is applied in the direction of drying/impregnation machines, can solve the problems of scattered core pack arrangement, etc., and achieve the effect of increasing the feeding speed, simple structure setting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

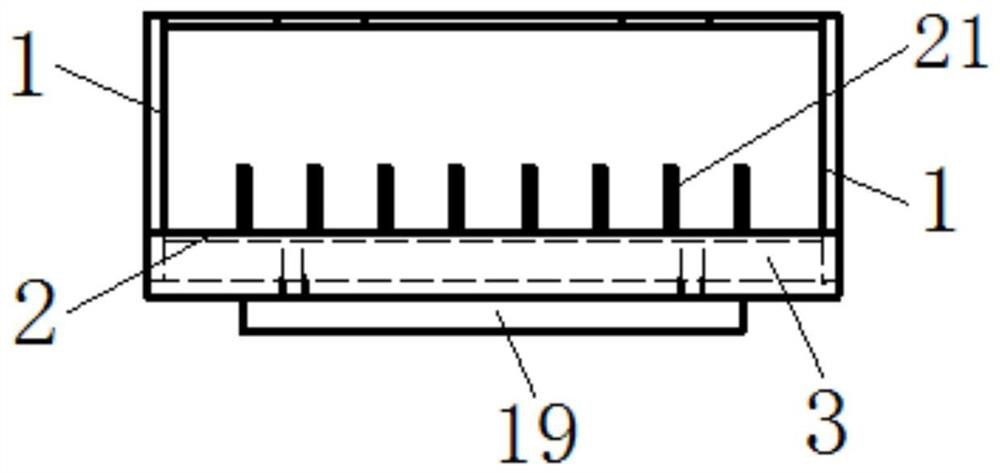

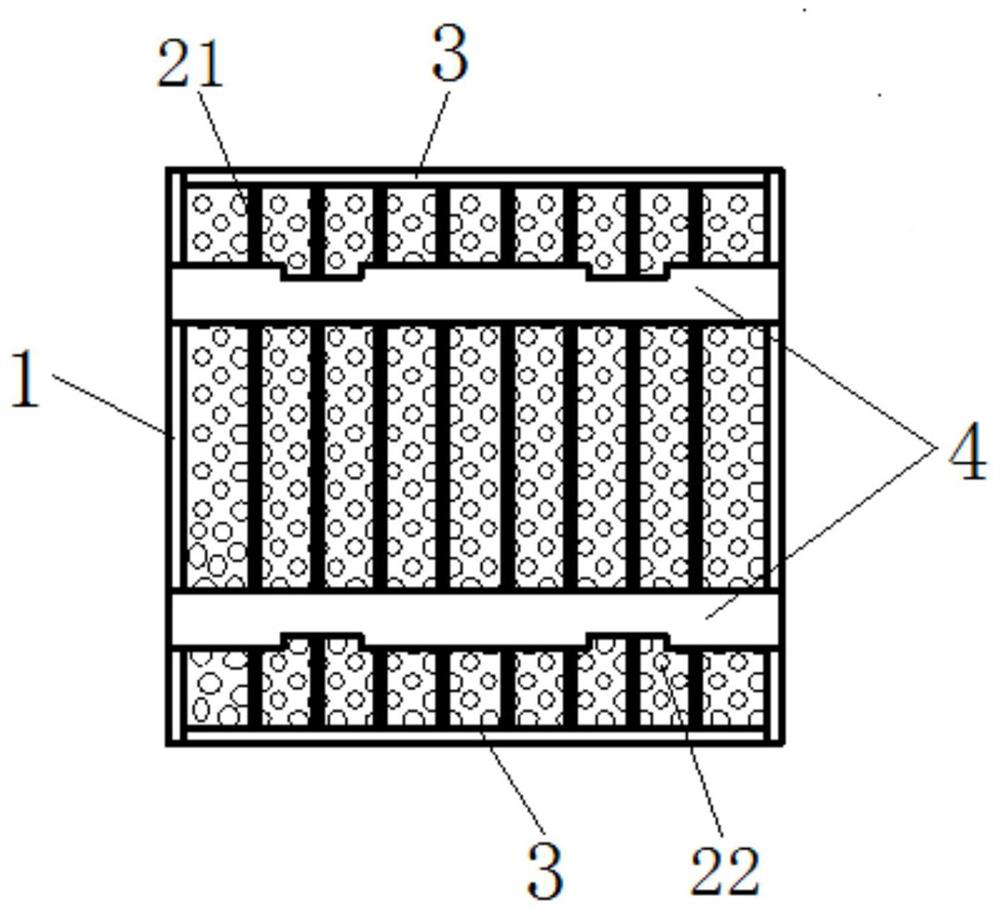

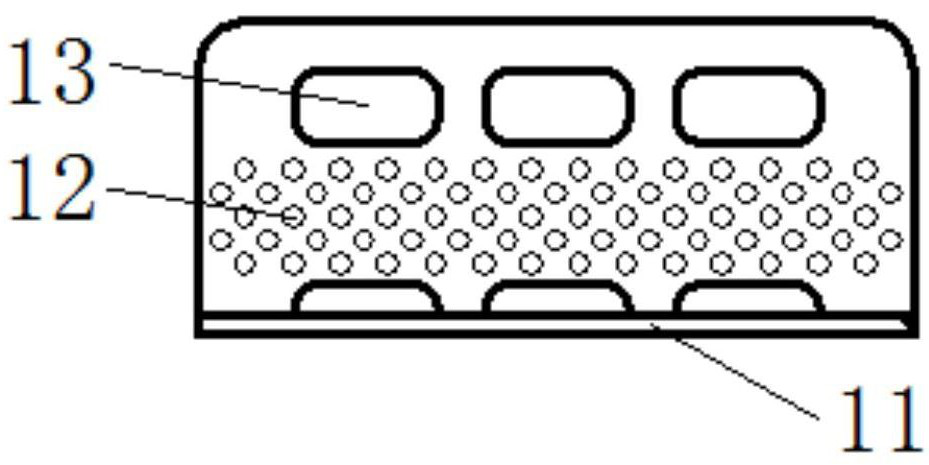

[0030] like Figure 1-3 As shown in the figure, an impregnation basket used for immersion and deliquoring of capacitor cores includes two impregnation basket side plates 1, a bottom plate 2 and two first baffle plates 3 arranged opposite to each other; the two impregnation basket side plates described 1 is provided with a second baffle 11 (the side plate 1 of the impregnation basket is provided with a second baffle 11 to form an L-shaped impregnation basket side plate); the two ends of the first baffle 3 are respectively connected to The two side plates 1 of the impregnation basket are arranged oppositely; the bottom plate 2 is movably arranged between the two side plates 1 of the impregnation basket and the two first baffles 3, and the two ends of the bottom plate 2 They are respectively overlapped on the second baffle plate 11 ; a plurality of partition plates 21 are arranged at equal intervals on the bottom plate 2 , and the distance between two adjacent partition plates 21...

Embodiment 2

[0033] like Figure 4 As shown in the figure, an automatic feeding system for impregnation baskets includes slide rails 5, a pallet 6 for carrying the impregnation baskets in the above-mentioned embodiment 1, a conveying trough 7, a pushing device 8, a sliding plate 9, and a first driving device 10. and the second driving device 14; the pallet 6 is fixedly installed on the sliding plate 9, the sliding plate 9 is slidably connected to the sliding rail 5, and is driven by the first driving device 10 where it is located. Move on the slide rail 5; the pallet 6 is fixedly provided with a top plate 61 for lifting the bottom plate 2 (the top plate 61 is provided in two pieces and is symmetrical on both sides of the pallet 6) ; The described pallet 6 is also movably provided with a splint 62 for clamping the side plate 1 of the impregnation basket (the splint 62 is also arranged in two pieces, and is symmetrically at both ends of the pallet 6); The second driving device 14 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com