Process for treating bauxite physical enrichment residues

A technology of mineral physics and bauxite, applied in the fields of aluminum compounds, chemical instruments and methods, preparation of alkali metal aluminates/alumina/aluminum hydroxide, etc., which can solve the problems of no recycling options and the inability to extract aluminum in an economical way.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

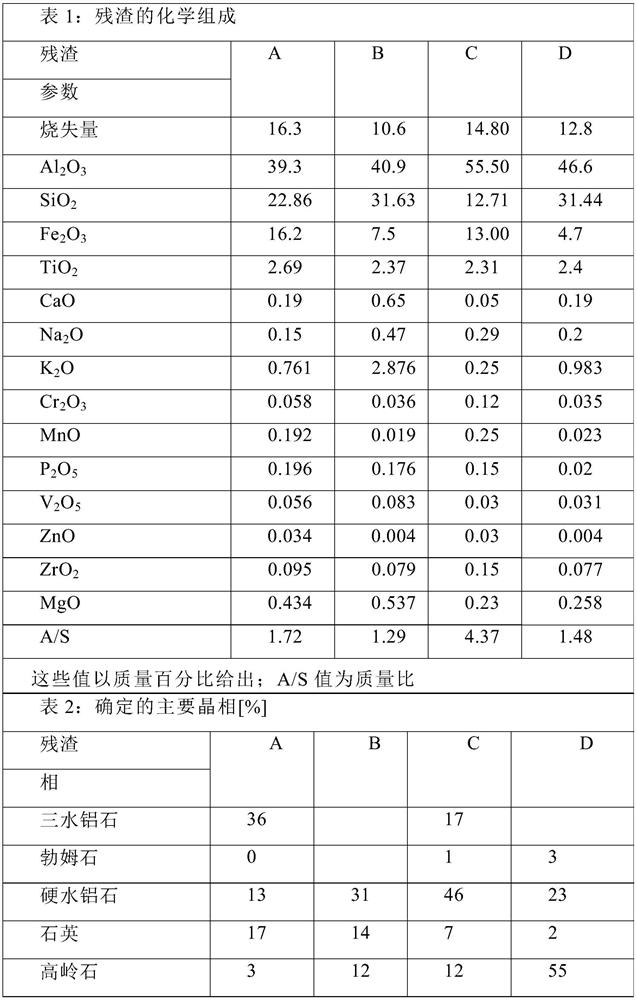

[0184] 1) Residue selection and analysis

[0185] Four batches of bauxite (labeled A, B, C and D) were subjected to one or the other of two physical enrichment methods; these physical enrichment methods applied to these batches of bauxite The set method is an industrial method known to those skilled in the art.

[0186] According to the first method of physical enrichment, the bauxite is crushed and then wet sieved on a vibrating screen. The finest particles with a very high silica concentration are carried away by the wash water and are excluded; the rest form residues (residues A, B and C) which will then be processed by the method according to the invention.

[0187] According to the second physical enrichment method, finely ground bauxite (average particle size about 200 μm) is subjected to flotation using chemical auxiliaries to adsorb the target minerals found in the floating material at that time, so as to be separated from the The mineral residue (residue D) is sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com