Extraction equipment

A technology of extraction equipment and extraction chamber, which is applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve the problems of low extraction and separation efficiency, layering does not obviously affect the extraction results, etc., so as to improve the extraction results and increase the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

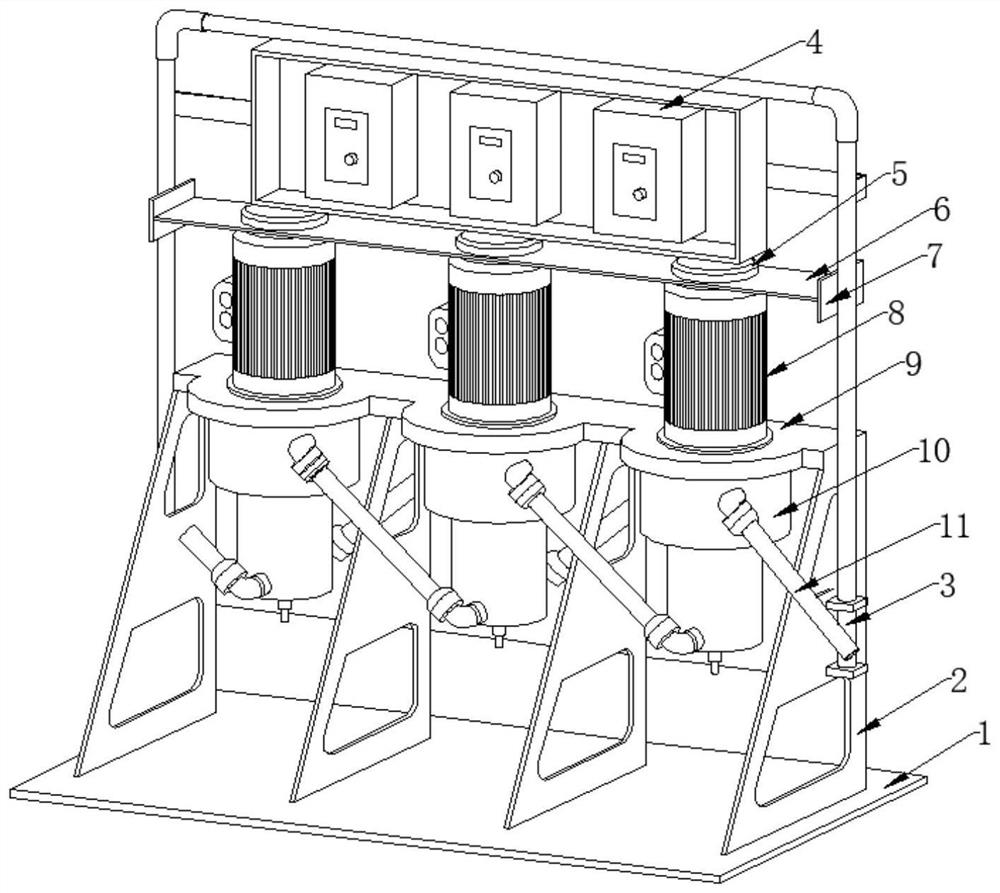

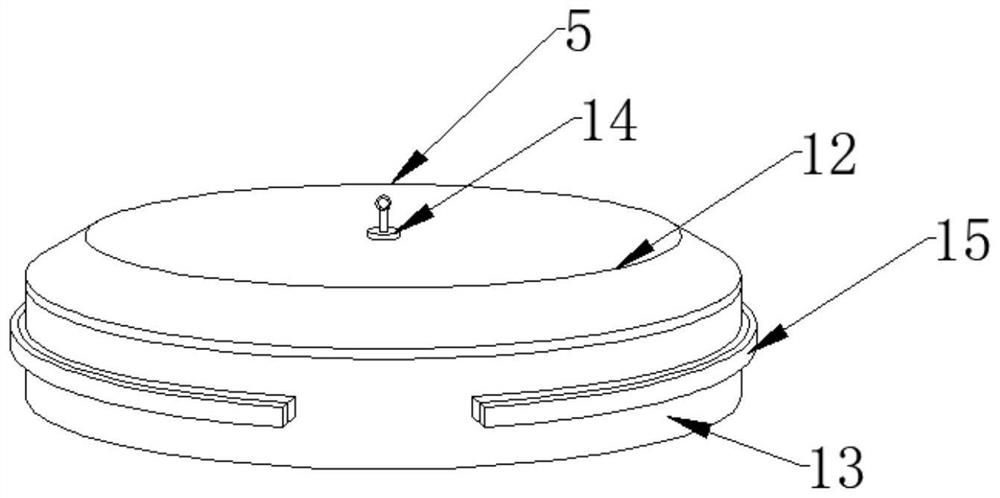

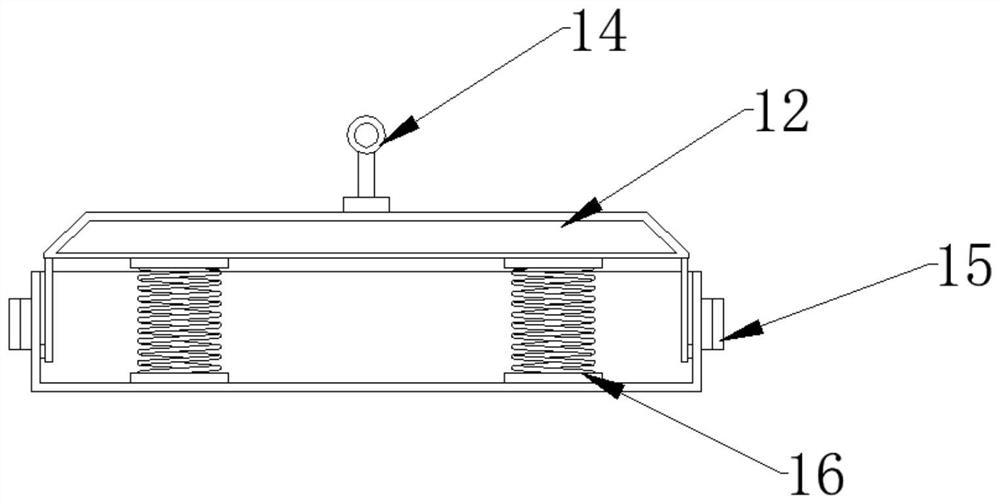

[0027] like Figure 1-6 As shown, the present invention provides an extraction equipment, comprising a base 1, a bracket 2, a support rod 3 and a control panel 4, a damping ring 5 is installed at the bottom end of the control panel 4, and a transverse Plate 6, two ends of the horizontal plate 6 are installed with connecting vertical plates 7, the bottom end of the damping ring 5 is installed with a rotating motor 8, the bottom end of the rotating motor 8 is provided with a connecting platform 9, and the bottom of the connecting platform 9 An extraction cavity 10 is installed at the end, the surface of the extraction cavity 10 is provided with a connecting pipe 11, the damping ring 5 includes an upper cover 12 and a lower base 13, a snap ring 14 is arranged in the middle of the surface of the upper cover 12, and the lower base The middle surface of 13 is provided with a side ring 15, a telescopic spring 16 is installed inside the lower base 13, the side ring 15 includes a coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com