Automatic unpowered glue-making conveying line

A transportation line and power technology, which is applied in the field of automatic non-powered rubber production transportation line, can solve the problems of poor demoulding effect, high investment cost and maintenance cost, unfavorable energy saving and emission reduction, etc., and achieve high-quality automatic continuous operation, Effect of improving aging and transportation efficiency and reducing cost of control equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

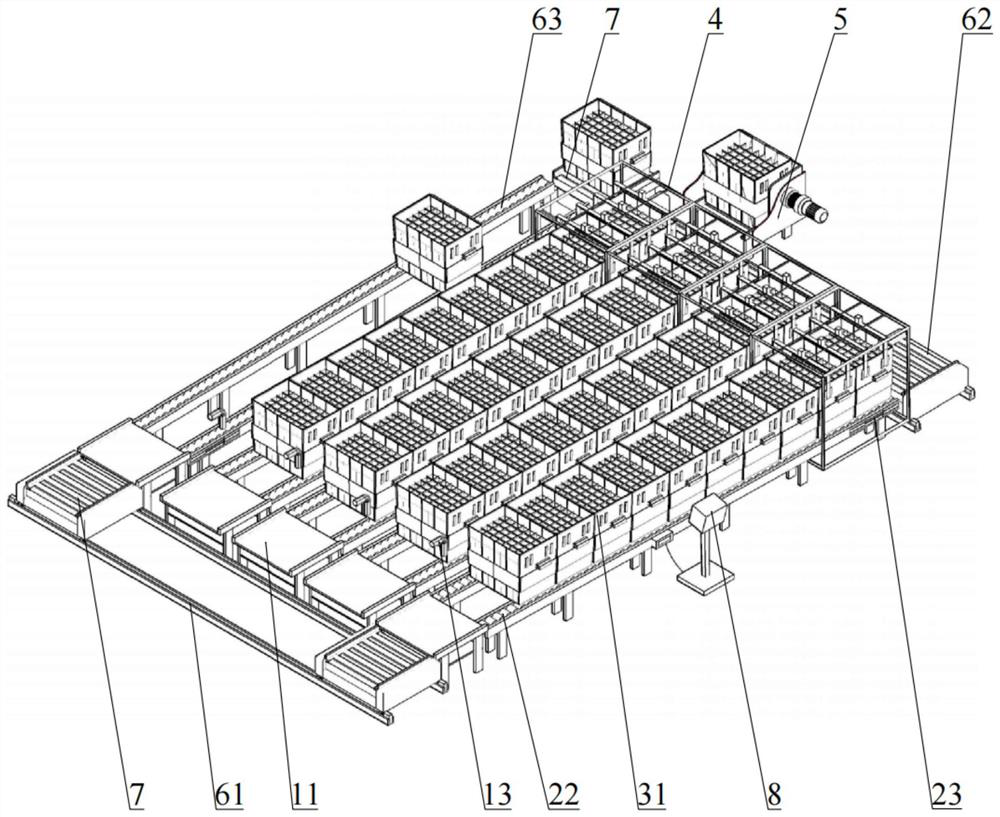

[0028] like figure 1 As shown, the automatic non-powered rubber production transportation line includes a hopper 31, an RGV trolley 7, and a glue injection mechanism, a conveying line, a clamping mechanism 4, and a turning mechanism 5 arranged in sequence. The hopper 31 completes the glue injection at the glue injection mechanism along the The conveyor line slips, specifically, the glue injection mechanism is provided with a glue injection conveyor belt 11, the glue injection conveyor belt 11 is conveyed in a direction close to the conveyor line, the glue injection conveyor belt 11 is provided with a glue injection port 13, and the glue injection mechanism is provided with a glue injection Glue scales. The silicone stock solution is injected into the hopper 31 through the glue injection port 13, and after the silicone stock solution in the hopper 31 reaches the rated weight measured by the glue injection weighing device, the glue injection conveyor belt 11 drives the hopper 31...

Embodiment 2

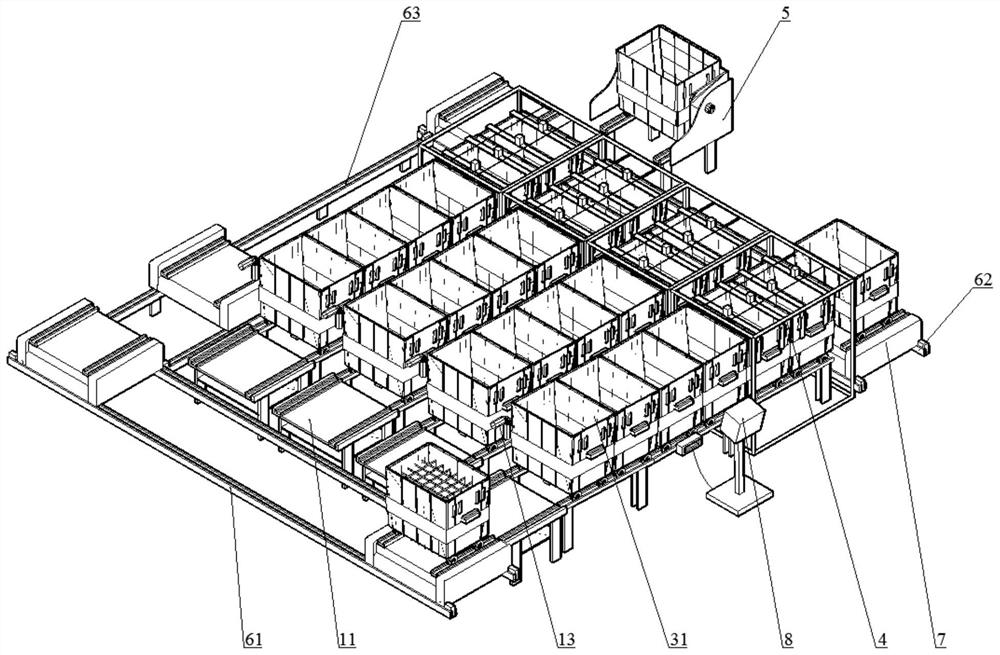

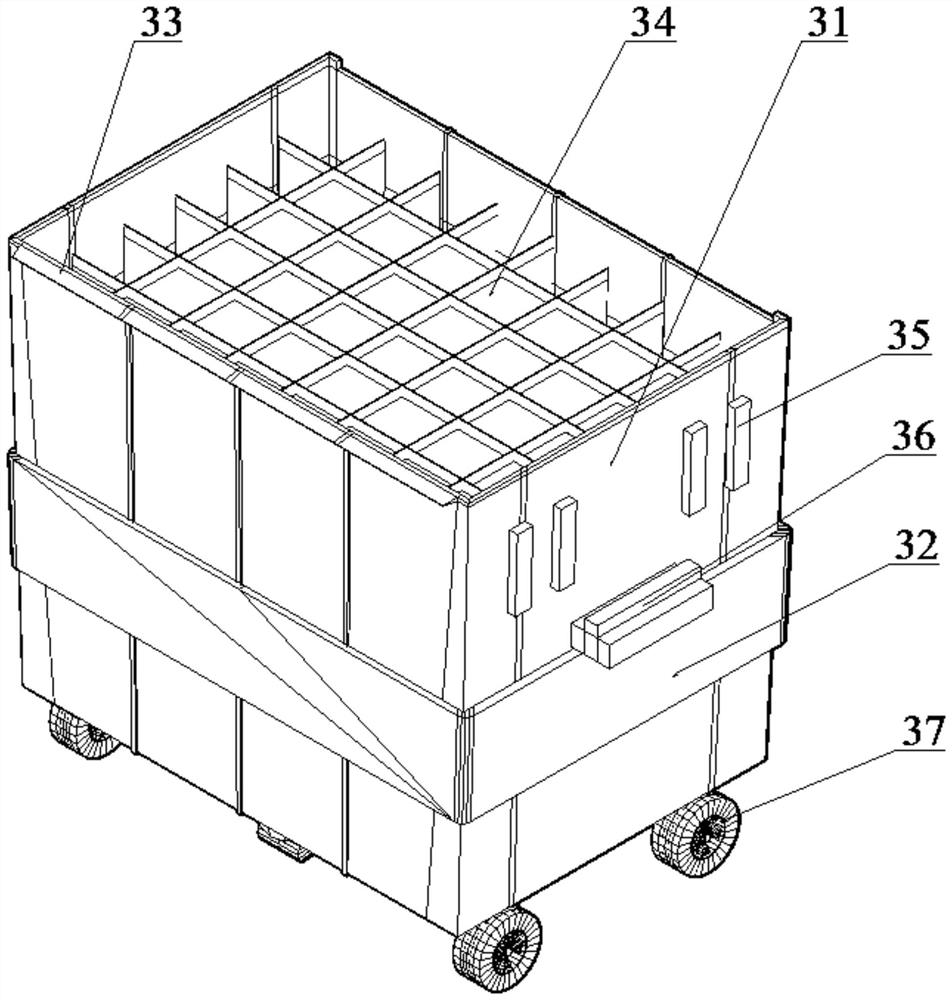

[0036] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the conveying line 2 adopts a guide rail structure, and rollers 37 are arranged at the bottom of the hopper 31, and the movement of the hopper 31 is completed by the cooperation of the rollers 37 and the conveying line 2 to facilitate the movement of the bottom of the hopper 31. The bearing is replaced, the end of the roller installation shaft at the bottom of the hopper 31 hinged bearing buckle 38, such as Figure 8 shown. The bearing buckle 38 is rotated to the state collinear with the installation shaft, the replacement of the roller 37 and the bearing can be carried out, and the bearing buckle 38 is rotated to a state perpendicular to the installation shaft, and the fixing of the roller 37 and the bearing can be completed. In this embodiment, the return line 63 is composed of the RGV trolley 7 and guide rails, and the RGV trolley 7 transports the empty hopper that has been flip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com