Intelligent material bin and machining center

An intelligent, silo technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low assembly efficiency, long occupation time, low production efficiency, etc., to improve production efficiency and reduce waiting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]In the prior art, a machining center usually includes a machine tool and a tool library. The tool manipulator on the machine tool can communicate with the tool library to replace different tools, thereby realizing different processing techniques for the workpiece, shortening the auxiliary operation time of the workpiece, and improving the efficiency of the tool. Machining efficiency of complex workpieces. However, after the processing operation is completed, the staff needs to take out the finished workpiece from the outside, and then put the workpiece to be processed, so as to continue the processing. Since the staff may not be at the station temporarily, and the efficiency of manual assembly is low, the processing In the process of changing the workpiece, the center takes a long time, and the auxiliary operation time is long, which reduces the production efficiency of the machining center.

[0051] In order to solve the above problems, this embodiment provides a machin...

Embodiment 2

[0071] The difference between this embodiment and the first embodiment lies in that the structure of the machining center is different.

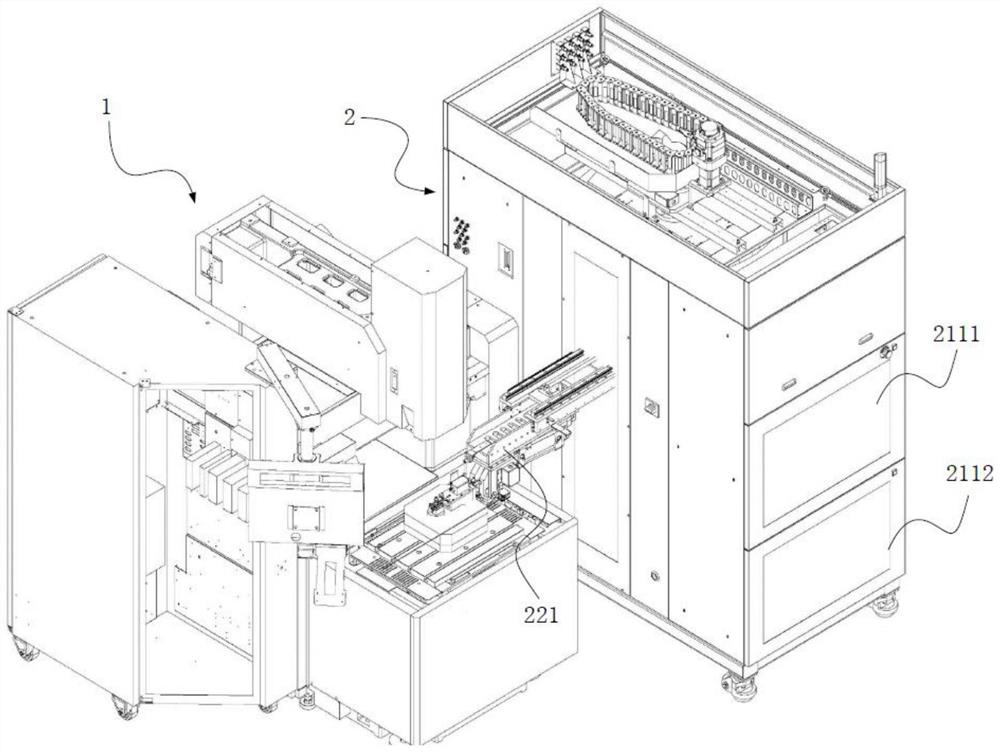

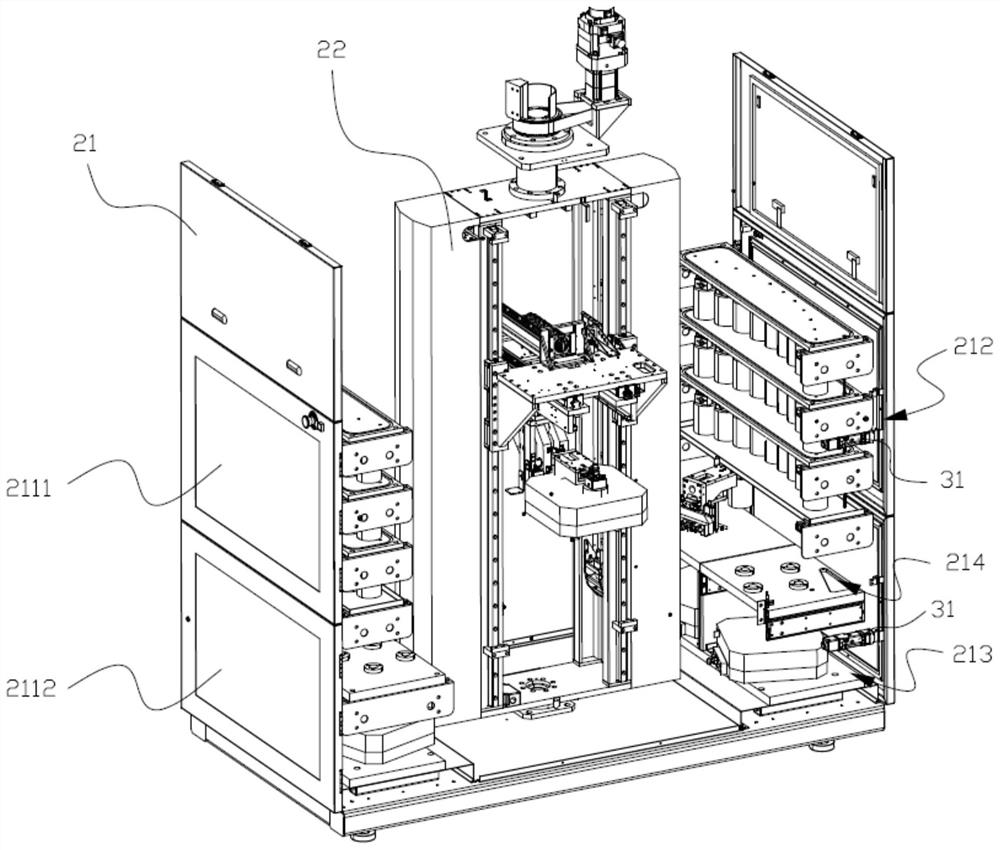

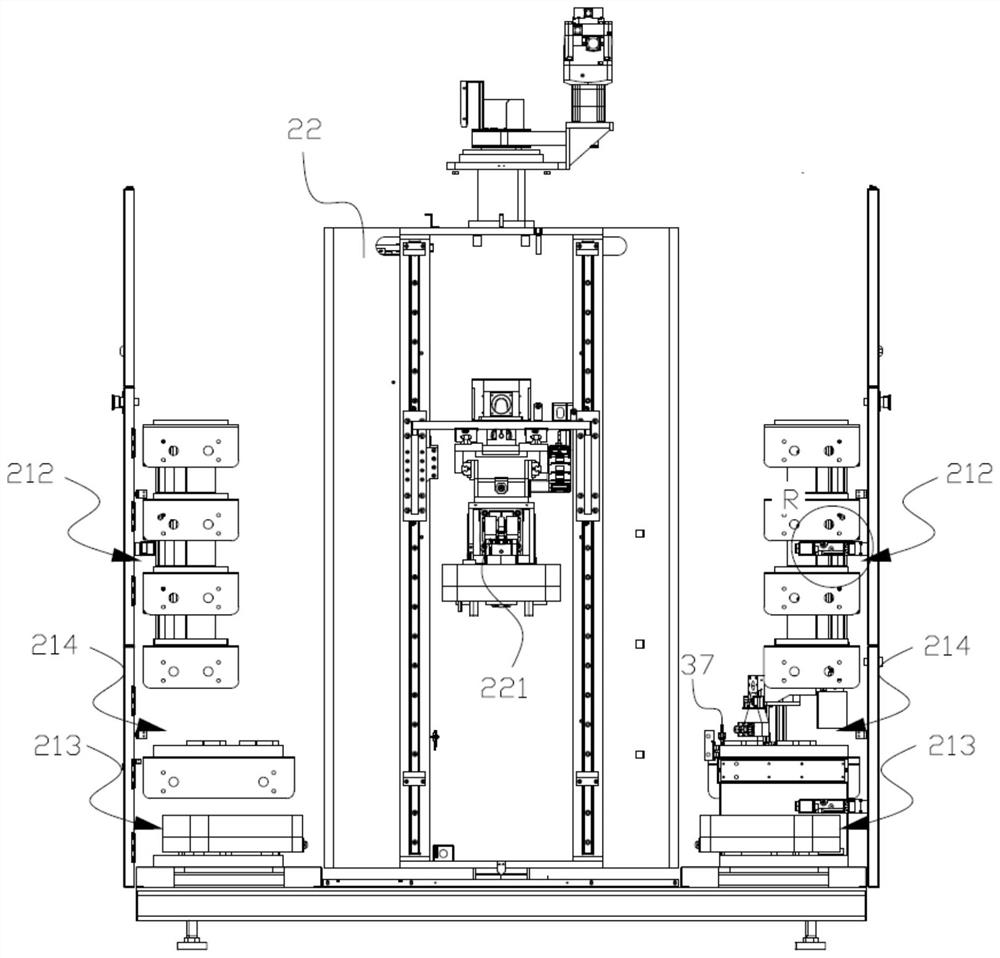

[0072] Specifically, in this embodiment, the machining center includes a pair of machine tools 1 and an intelligent storage bin 2 .

[0073] Wherein, the pair of machine tools 1 is a milling machine and an electric discharge machine. The cross-section of the material rack 21 is rectangular, and the transfer device 22 is arranged at the center of the material rack 21. A pair of relatively shorter sides of the material rack 21 are provided with a first placement area 212, a second placement area 213 and a second placement area 213. Three placement areas 214, the moving end of the transfer mechanism can be moved out of the material rack 21 by a pair of longer sides of the material rack 21, a milling machine and an electric discharge machine are respectively arranged on the outside of the material rack 21, and respectively Adjacent to a pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com