Intelligent automatic packaging method for red ginseng

A packaging method and automatic packaging technology, applied in packaging and other directions, can solve the problems of reducing product quality, high labor costs, easy to appear mildew, etc., and achieve the effect of improving product quality, improving labor efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

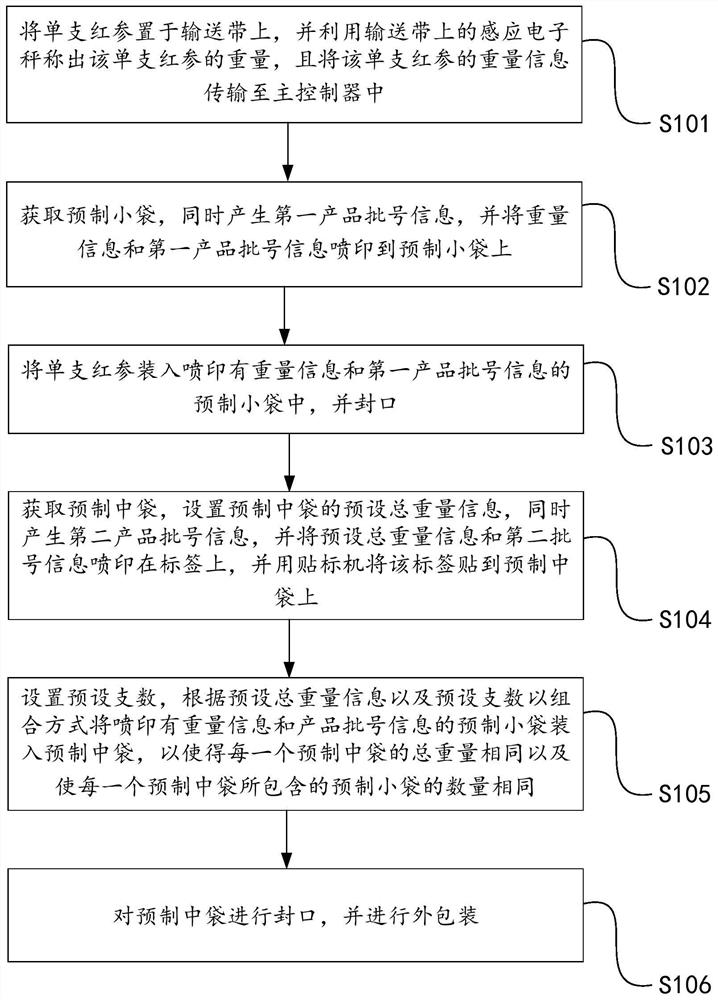

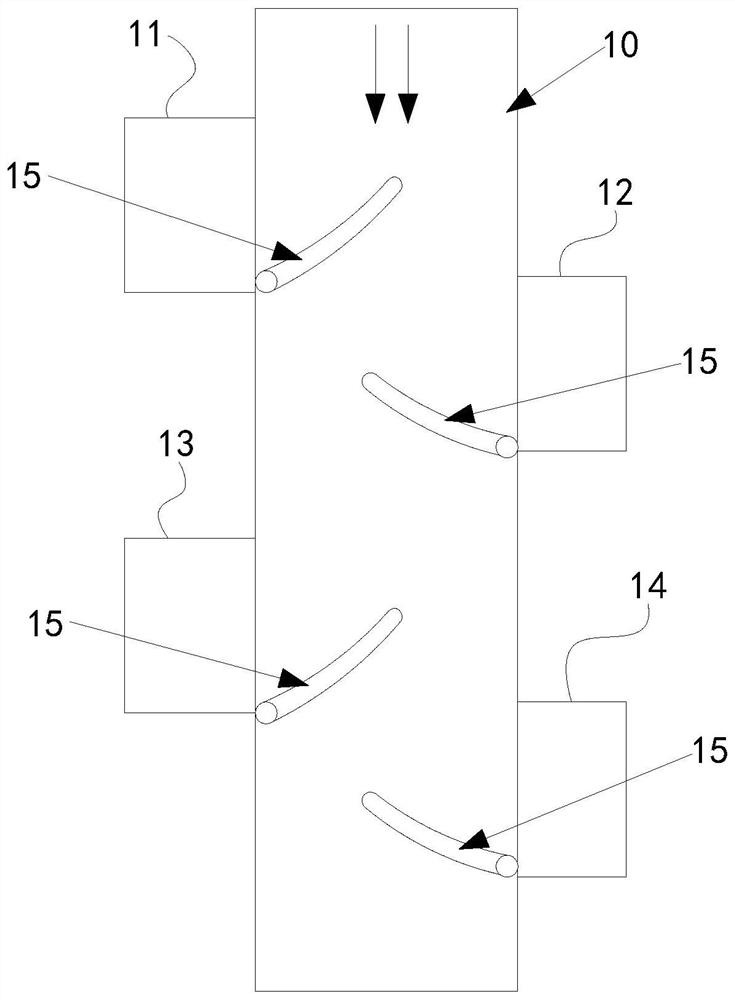

[0018] see figure 1 , the red ginseng intelligent automatic packaging method disclosed in the present invention comprises:

[0019] Step S101: Put a single red ginseng on the conveyor belt, use the induction electronic scale on the conveyor belt to weigh the single red ginseng, and transmit the weight information of the single red ginseng to the main controller.

[0020] It should be understood that, in step S101, if the conveyor belt is equipped with an induction electronic scale, when a red ginseng is placed on the conveyor belt, the induction electronic scale can immediately weigh it.

[0021] Step S102: Obtain the prefabricated pouch, generate the first product batch number information at the same time, and print the weight information and the first product batch number information on the prefabricated pouch.

[0022] Step S103: Put a single red ginseng into a prefabricated pouch printed with weight information and the batch number information of the first product, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com