Asymmetric spherical pipeline elbow for pneumatic transportation

A pipeline elbow, asymmetric technology, used in elbows, pipeline protection, pipes/pipe joints/fittings, etc., can solve problems such as damage to transported particles, erosion damage to pipe walls, and loss of kinetic energy of transported gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

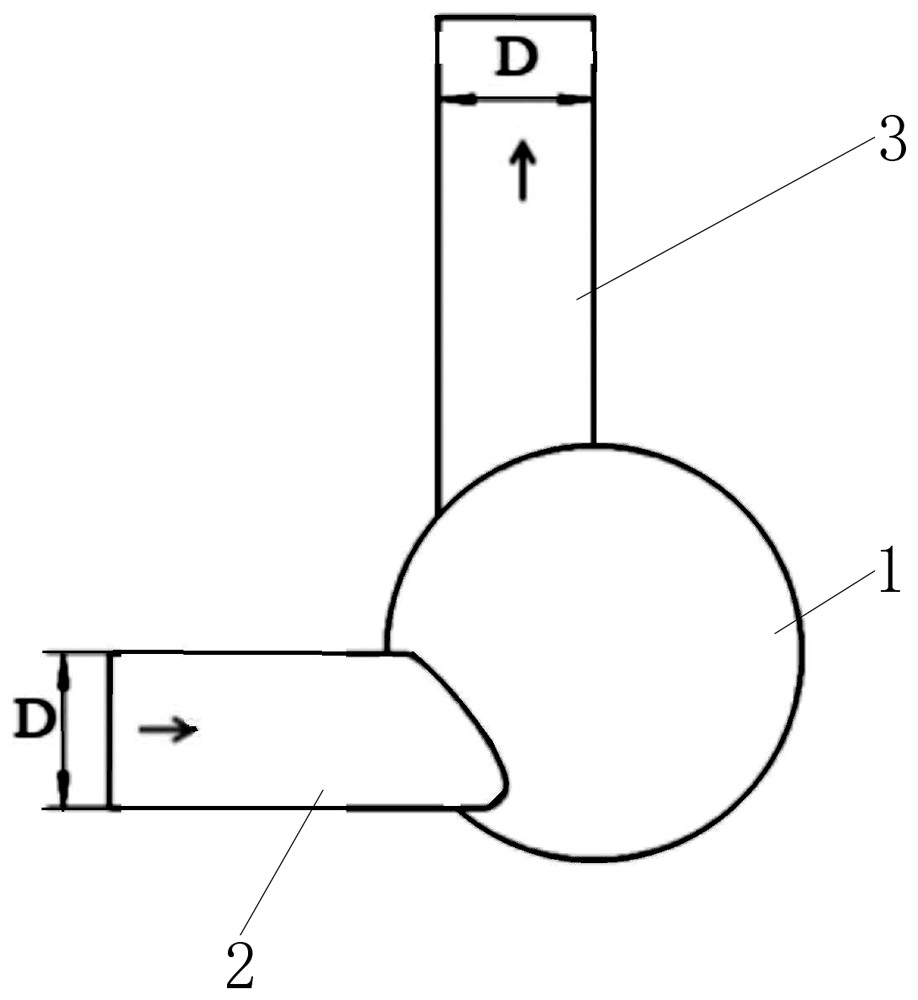

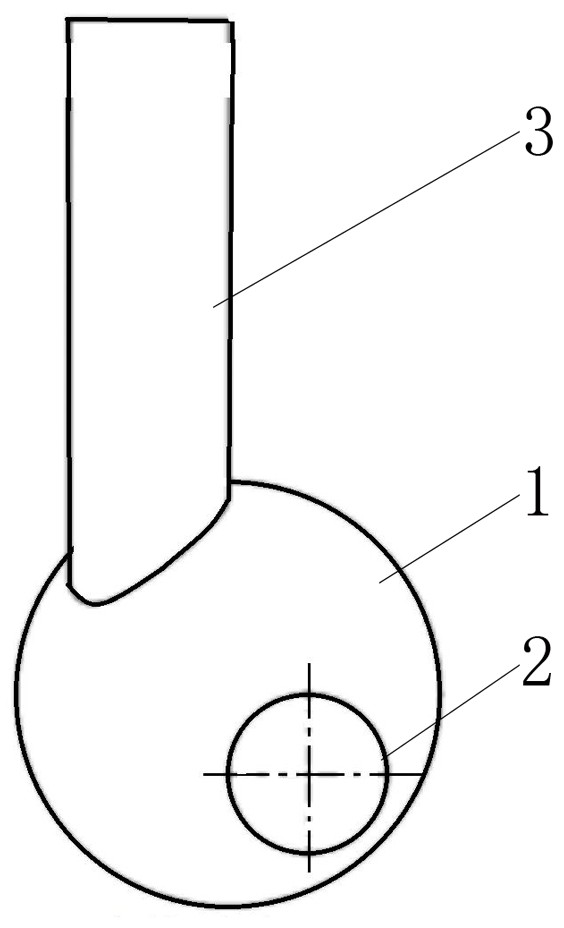

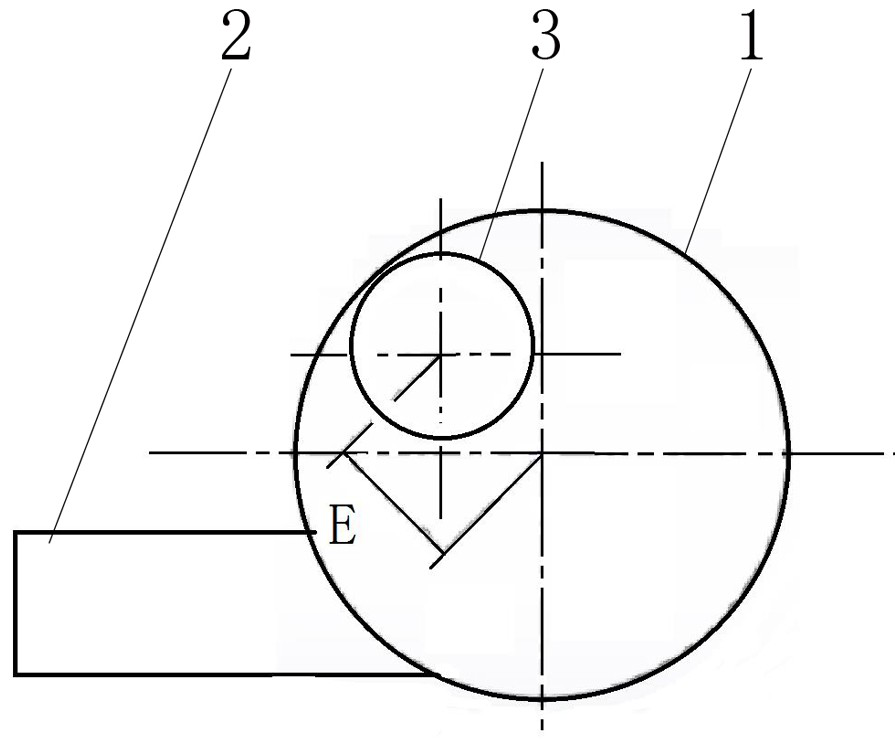

[0093] An asymmetric spherical pipe elbow for pneumatic transportation, including a spherical pipe elbow 1, a feed pipe 2 connected to the spherical pipe elbow 1 arranged horizontally, and the two are connected at the left front lower part of the spherical pipe elbow 1; The discharge pipe 3 communicating with the spherical pipe elbow 1 is vertically arranged, and the two are connected at the left rear upper part of the spherical pipe elbow 1; wherein, the inner diameter of the spherical pipe elbow 1 is 240 mm; the feed pipe 2 The inner diameter of the pipe is consistent with the inner diameter D of the discharge pipe 3, and the inner diameter D of both is 100mm; the distance from the center of the sphere of the spherical pipe elbow 1 to the axis of the discharge pipe 3 is the pipe eccentricity E, and the pipe eccentricity The distance from E is 75mm.

[0094] When the spherical pipe elbow 1 transports particles, the air velocity V is 30m / s; the diameter d of the particles is 6...

Embodiment 2

[0096] An asymmetric spherical pipe elbow for pneumatic transportation, including a spherical pipe elbow 1, a feed pipe 2 connected to the spherical pipe elbow 1 arranged horizontally, and the two are connected at the left front lower part of the spherical pipe elbow 1; The discharge pipe 3 communicating with the spherical pipe elbow 1 is vertically arranged, and the two are connected at the left rear upper part of the spherical pipe elbow 1; wherein, the inner diameter of the spherical pipe elbow 1 is 240 mm; the feed pipe 2 The inner diameter of the pipe is consistent with the inner diameter D of the discharge pipe 3, and the inner diameter D of both is 80mm; the distance from the center of the sphere of the spherical pipe elbow 1 to the axis of the discharge pipe 3 is the pipe eccentricity E, and the pipe eccentricity Distance E is 52mm.

[0097] When the spherical pipe elbow 1 transports particles, the air velocity V is 20m / s; the diameter d of the particles is 4mm, and th...

Embodiment 3

[0099] An asymmetric spherical pipe elbow for pneumatic transportation, including a spherical pipe elbow 1, a feed pipe 2 connected to the spherical pipe elbow 1 arranged horizontally, and the two are connected at the left front lower part of the spherical pipe elbow 1; The discharge pipe 3 communicating with the spherical pipe elbow 1 is vertically arranged, and the two are connected at the left rear upper part of the spherical pipe elbow 1; wherein, the inner diameter of the spherical pipe elbow 1 is 240 mm; the feed pipe 2 The inner diameter of the pipe is consistent with the inner diameter D of the discharge pipe 3, and the inner diameter D of both is 90mm; the distance from the center of the spherical pipe elbow 1 to the axis of the discharge pipe 3 is the pipe eccentricity E, and the pipe eccentricity The distance E is 63.5mm.

[0100] When the spherical pipe elbow 1 transports particles, the air velocity V is 25m / s; the diameter d of the particles is 4mm, and the densit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com