Drying, storing and conveying equipment for metal powder

A technology for metal powder and conveying equipment, which is used in drying, dryer, lighting and heating equipment to achieve the effect of good stability and high integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

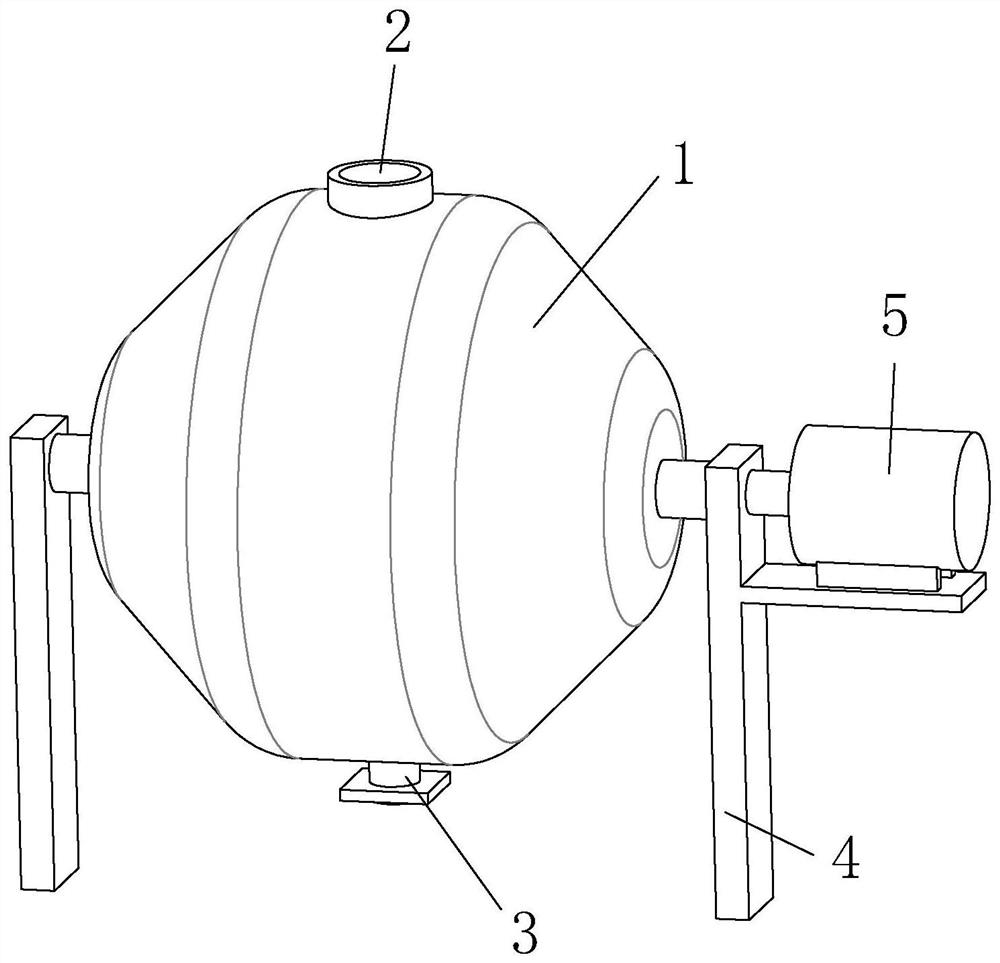

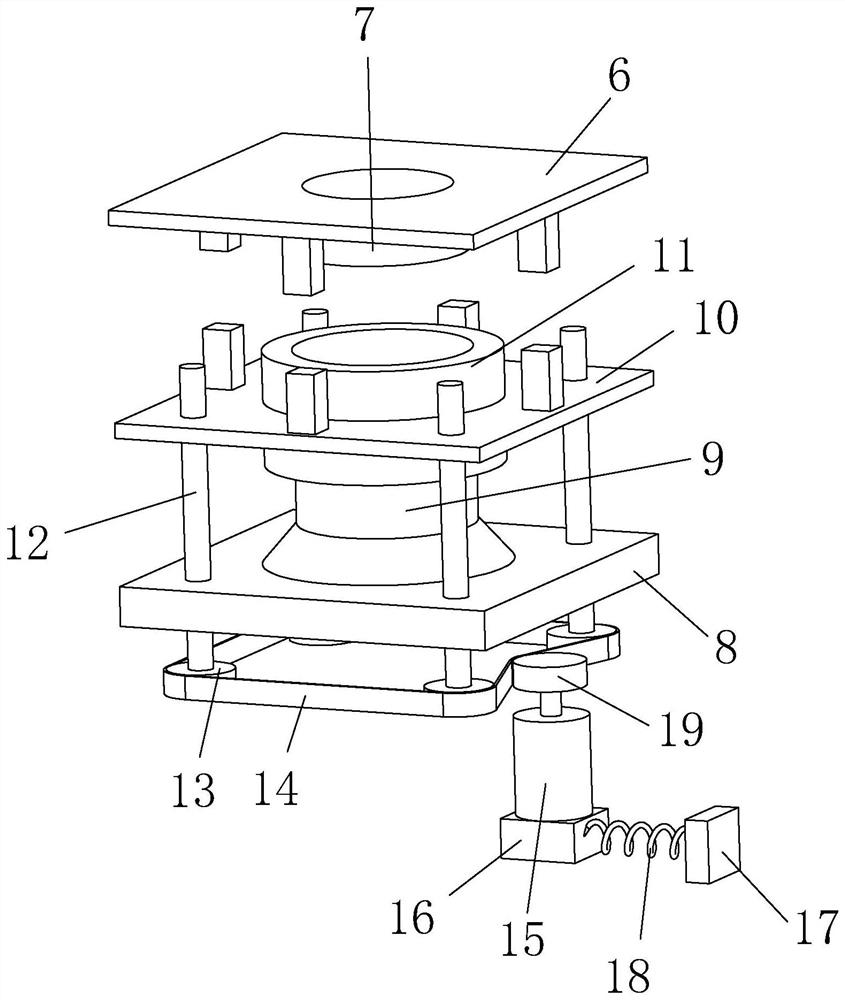

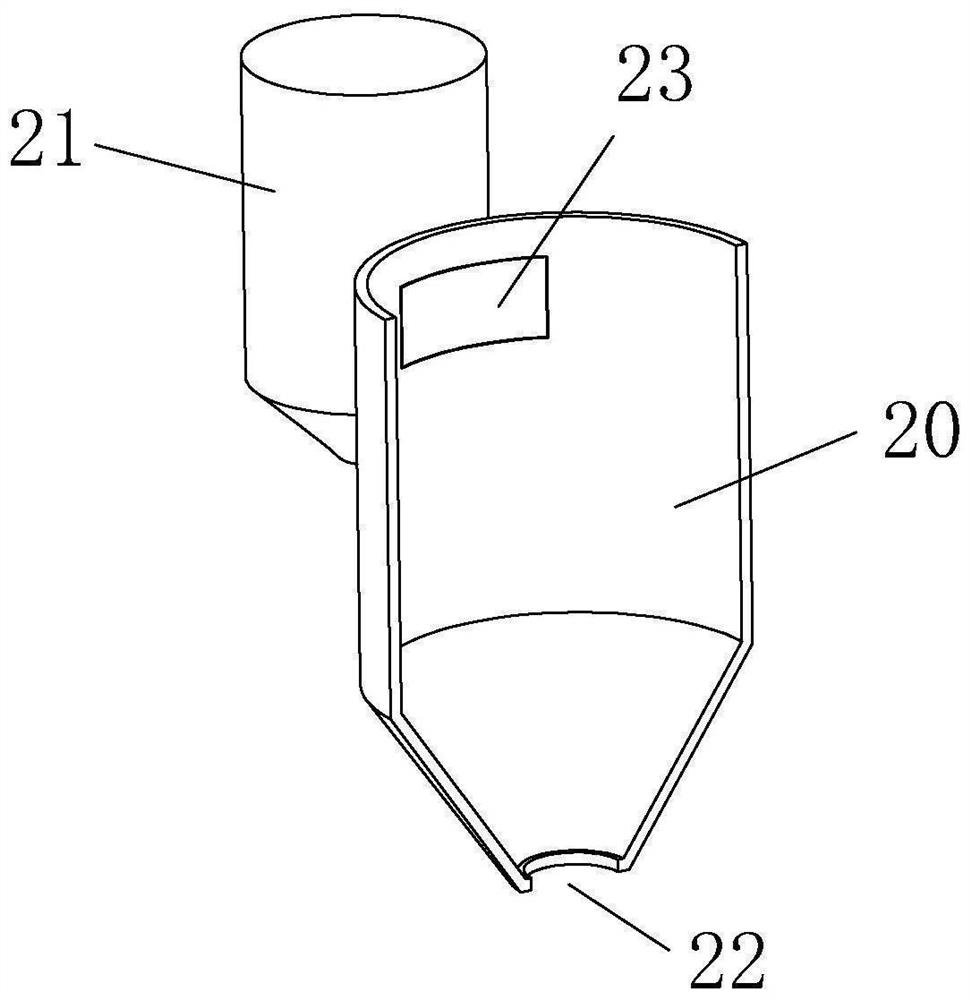

[0031] The metal powder drying, storage and conveying equipment includes a drying furnace 1 with a feeding port 2 and a discharging port 3, a feeding device for feeding metal powder materials into the drying furnace 1 from the feeding port 2, and a metal feeding device for temporarily storing metal powder. A storage and dedusting device for powder and dust removal, a pipeline for connecting the discharge port 3 of the drying furnace 1 with the storage and dedusting device, and a device for automatically connecting or separating the two between the discharge port 3 and the pipeline Automatic docking device, material amount detection and feeding self-stop device for detecting whether the feeding amount of the drying furnace 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com