Comprehensive peel treatment device of pineapple peeling equipment

A comprehensive processing and equipment technology, applied in the peeling, transportation and packaging of vegetables or fruits, and conveyor objects, etc., can solve the problems of unfruitful flowers, no preliminary treatment, inconvenient post-processing of peels, etc., and achieve a convenient transportation angle , easy to support the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

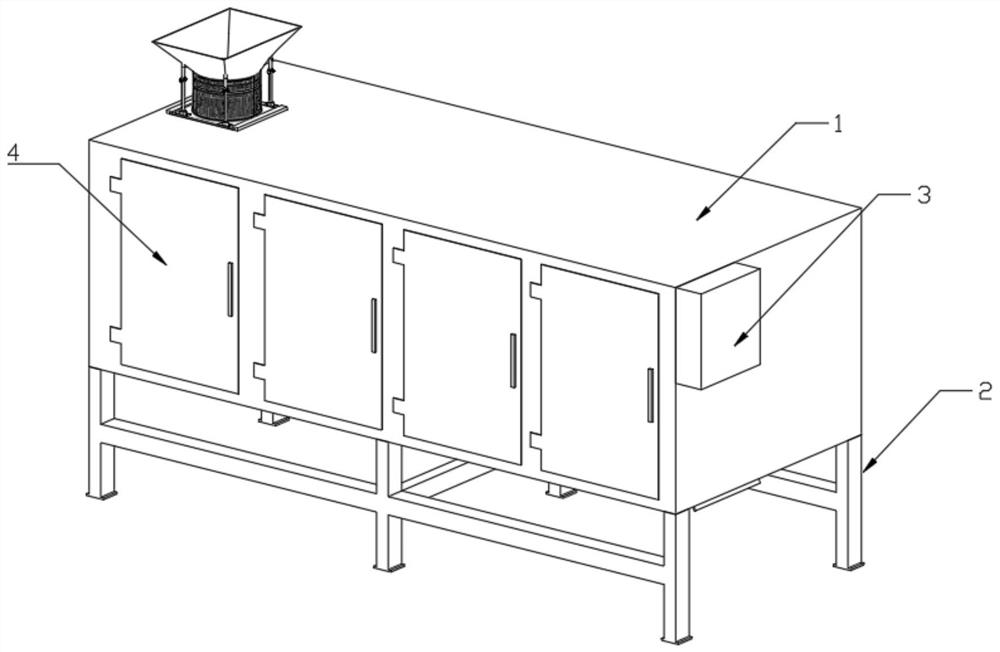

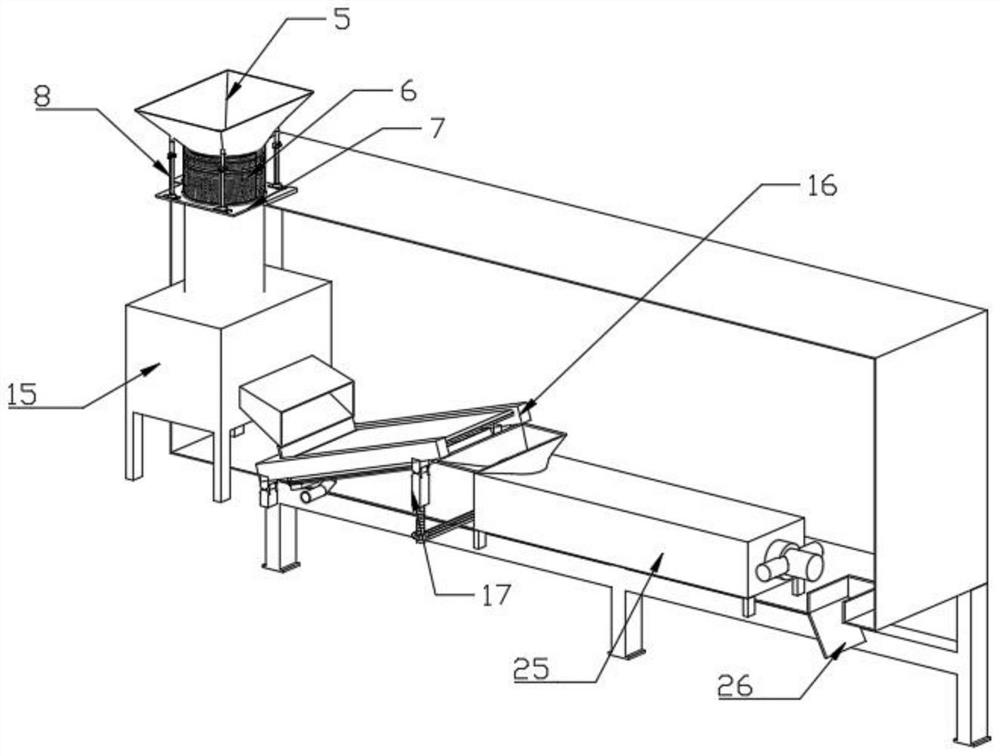

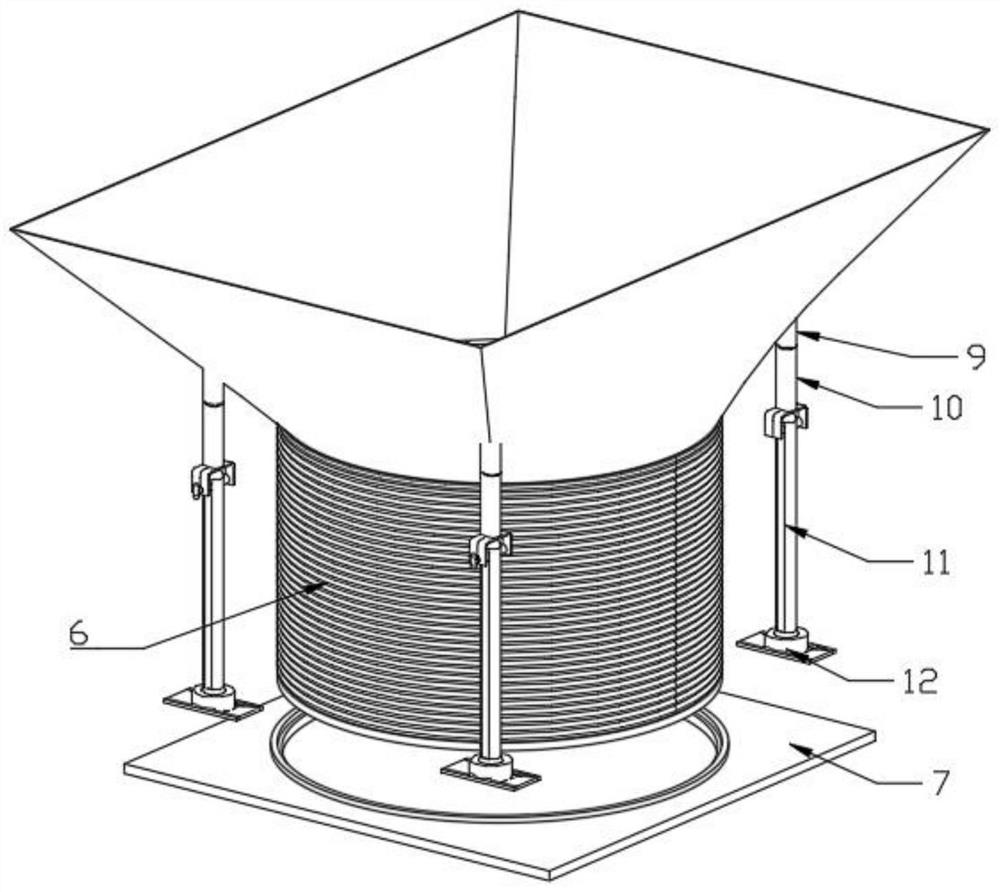

[0033] Such as Figure 1-9 As shown, a comprehensive peel processing device for pineapple peeling equipment provided by the present invention includes a box body 1, a supporting leg 2 is provided on the bottom wall of the box body 1, and a control box is also provided on the side wall body of the box body 1. 3. There are several maintenance doors 4 in the front wall of the box body 1, a feeding hopper 5 is arranged on the upper wall of the box body 1, and a connecting bellows 6 is arranged on the bottom wall of the feeding hopper 5, and the connecting bellows 6 The bottom wall is provided with a bottom plate 7, and several installation mechanisms 8 are also provided on the bottom wall of the feed hopper 5. The installation mechanism 8 includes a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap