Small low-flow-resistance swirl nozzle

A spray nozzle, low flow resistance technology, applied in the direction of spray device, spray device, etc., can solve the problems of difficulty in cleaning and maintenance of the nozzle, increase the total power consumption of the system, and reduce the spray quality, so as to optimize the system structure design and reduce the pump power. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

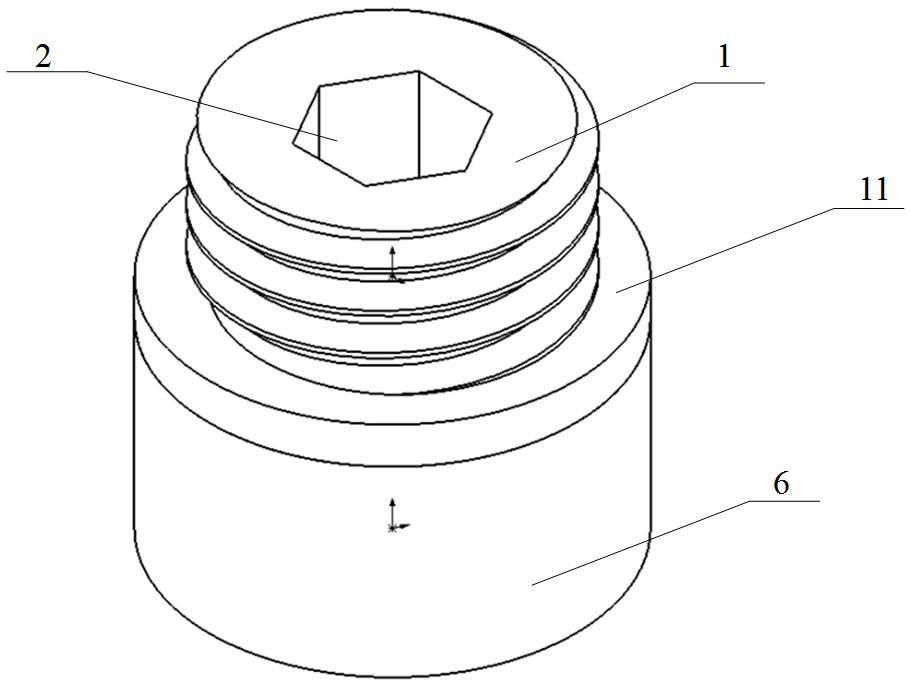

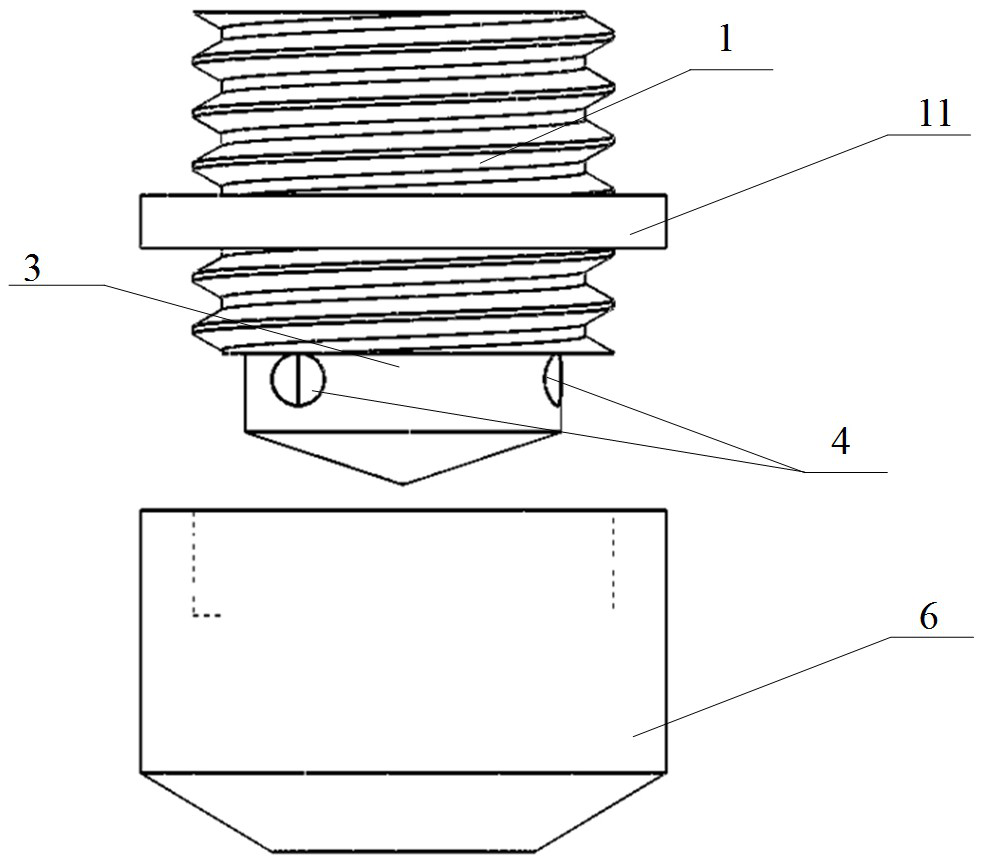

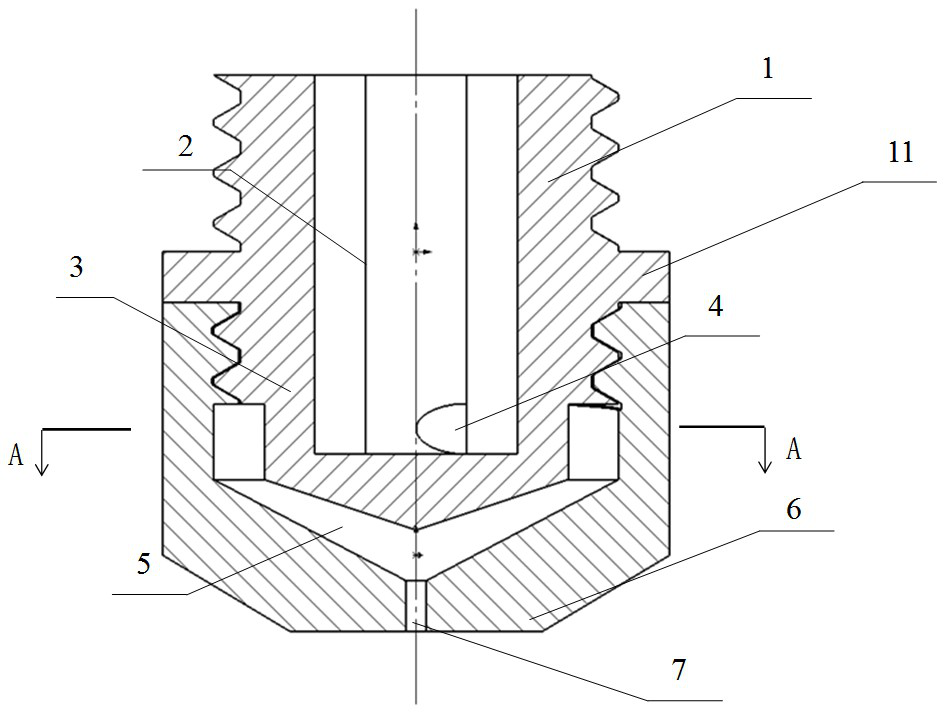

[0027] see figure 1 , a small swirl spray nozzle with low flow resistance includes a swirl joint 1 and a nozzle housing 6, which are coaxially fixedly connected by threads.

[0028] see figure 2 , The cyclone joint 1 is a screw rod, one axial end is a conical end 12, and the other axial end is provided with a hexagonal liquid inlet hole 2; the side length of the hexagon is 2 mm. The hole wall of the liquid inlet hole 2 adjacent to the conical end 12 is evenly distributed with three guide channels 4 through the hole wall, see Figure 4 . The diameter of the flow guide 4 is 1 mm, the distance h between the axis of the liquid inlet 2 and the axis of the flow guide 4 is 2 mm, and the ratio of the distance h to the diameter of the flow guide 4 is 2.0. The cyclone joint 1 where the outlets of the three flow guides 4 are located is cylindrical, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com