LED street lamp shell production device

A technology of LED street lamps and production devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of inconvenient removal of blanks, and achieve the effects of convenient operation, accelerated production, and improved material retrieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

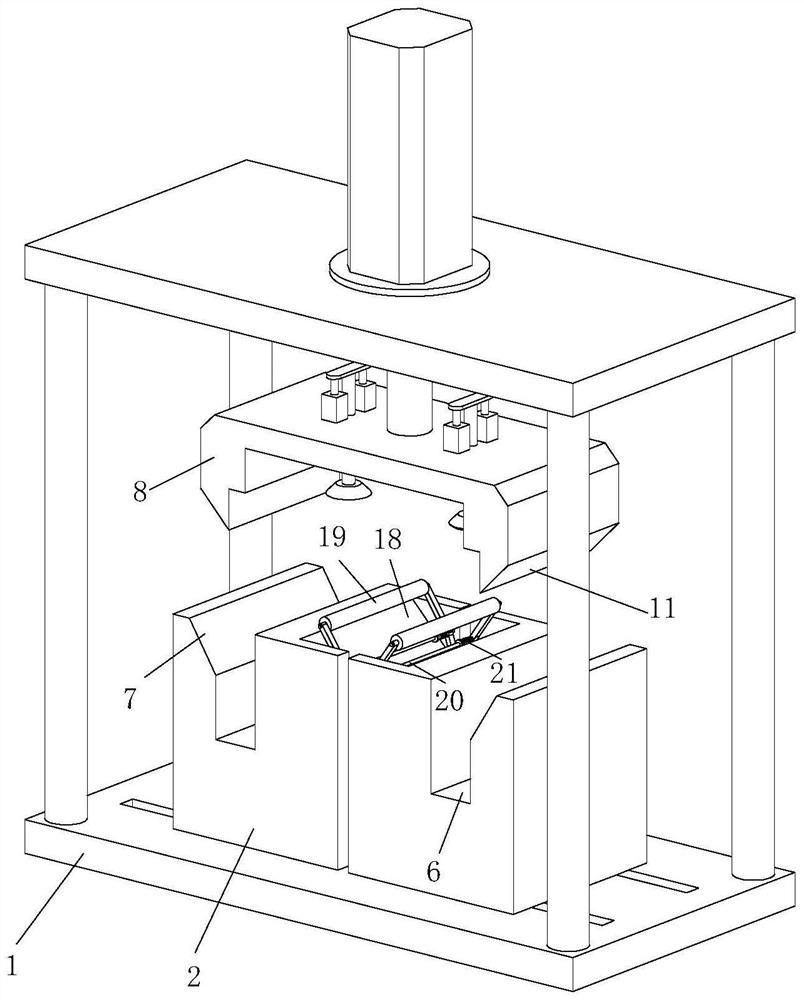

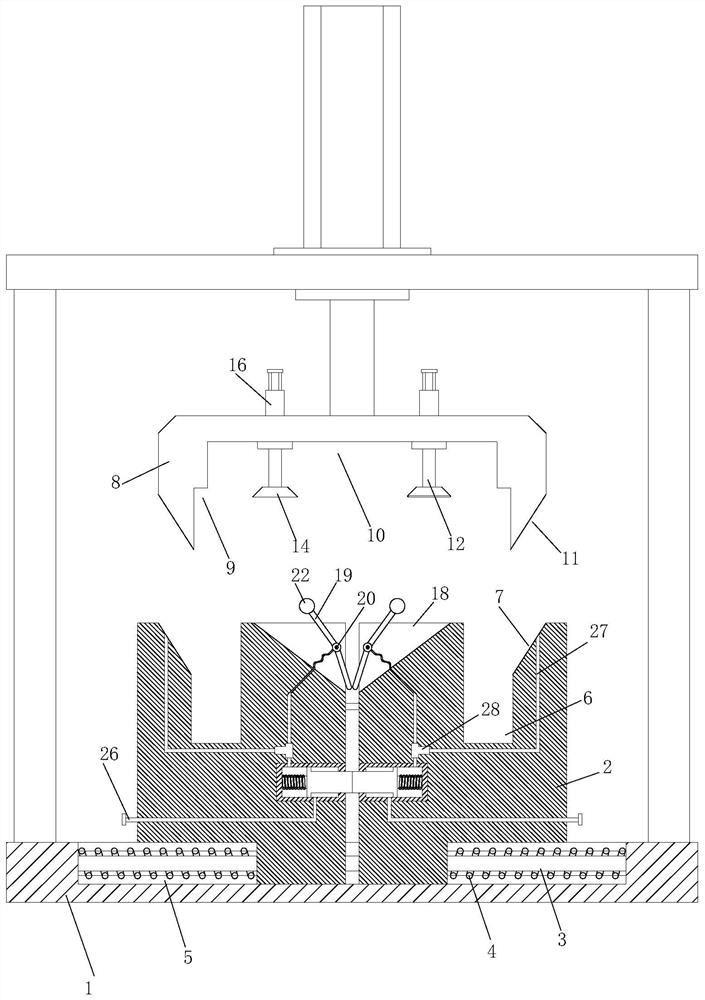

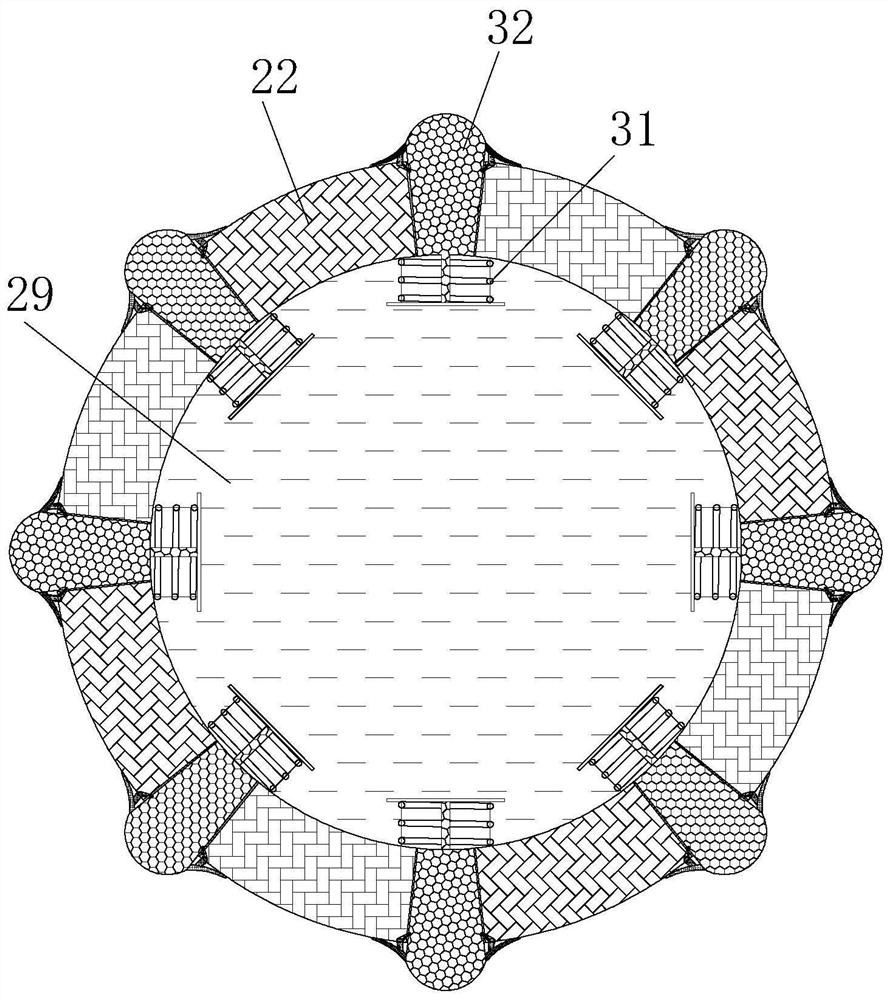

[0032] refer to Figure 1-5 , a production device for LED street lamp housings, comprising a base plate 1 and a stamping mechanism; the stamping mechanism is installed on the base plate 1, the stamping mechanism includes a fixed mold unit and a movable mold unit; the fixed mold unit includes a lower mold set in half 2. Guide rod 3 and No. 1 spring 4; the lower end surface of the lower mold 2 is slidably connected to the chute 5 provided on the bottom plate 1 through No. 1 spring 4, and the guide rod 3 is placed in the inner ring of No. 1 spring 4 to guide The rod 3 runs through the lower mold 2 and is fixedly connected to the inner end side wall of the chute 5; the upper end of the lower mold 2 is provided with a groove 6, and the notch of the groove 6 is provided with a No. 1 slope 7 near the outer edge;

[0033] The movable mold unit includes an upper mold 8; the upper end of the upper mold 8 is connected to a hydraulic cylinder, the hydraulic cylinder is fixed on the base p...

Embodiment 2

[0043] refer to Figure 6 , Comparative Example 1, as another embodiment of the present invention, wherein the branch of the oil outlet pipeline 27 extends to the No. 1 slope 7, and the lubricating oil flows to the No. 1 slope 7, so that a A layer of oil film reduces the wear between the No. 1 slope 7 and the No. 2 slope 11, and prolongs the service life of the lower die 2 and the upper die 8.

[0044] Working principle: first place the plate on the lower mold 2, then push down the upper mold 8 by controlling the hydraulic cylinder, the upper mold 8 gradually approaches the lower mold 2, and in the process of approaching, the first slope 7 first sticks to the second slope 11 With extrusion, the two lower molds 2 are separated from each other, and finally the two sides of the upper mold 8 are embedded in the groove 6, and the inner top surface of the first-level concave portion 9 presses down on the plate, and the plate is bent and attached to the inner wall of the groove 6 At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com