Automobile stator and rotor punching sheet deburring device

A stator-rotor and deburring technology, which is applied to grinding drive devices, manufacturing tools, grinding feed motion, etc., can solve problems such as low efficiency and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiment of the present application discloses a deburring device for an automobile stator and rotor.

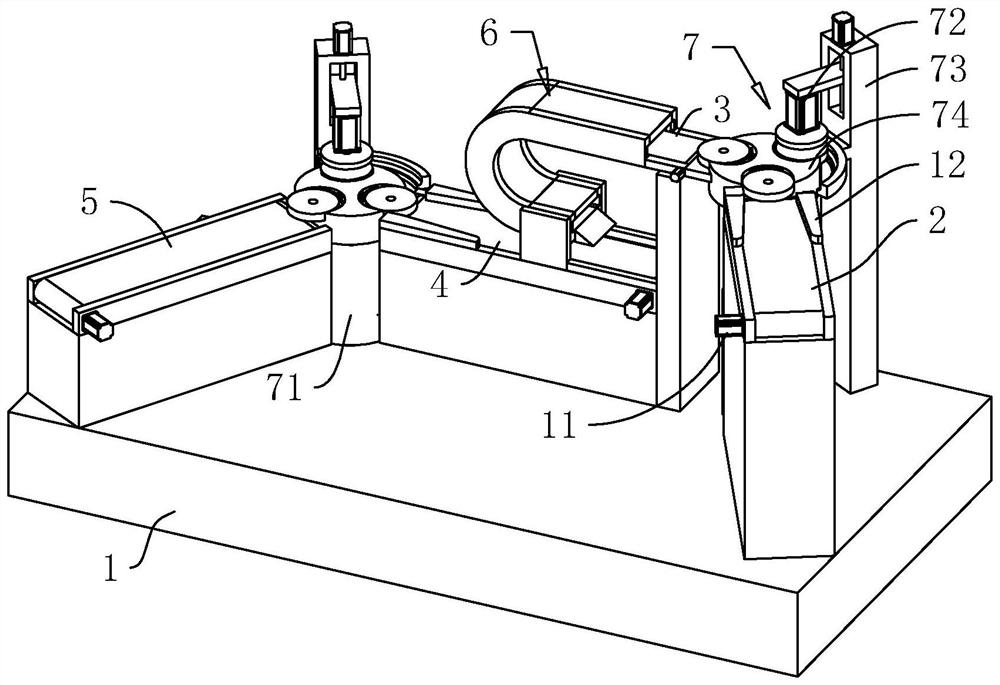

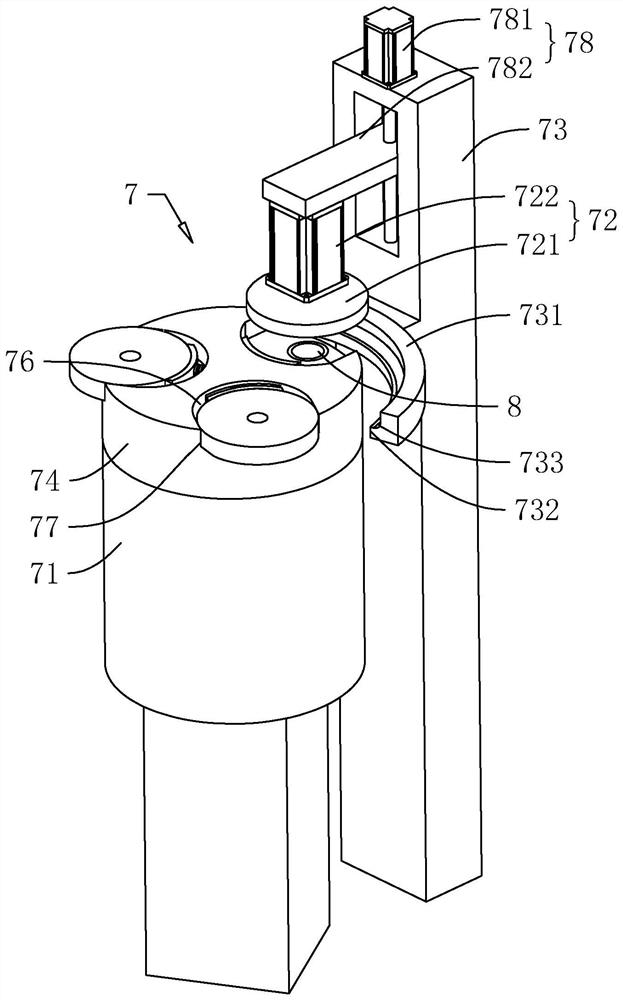

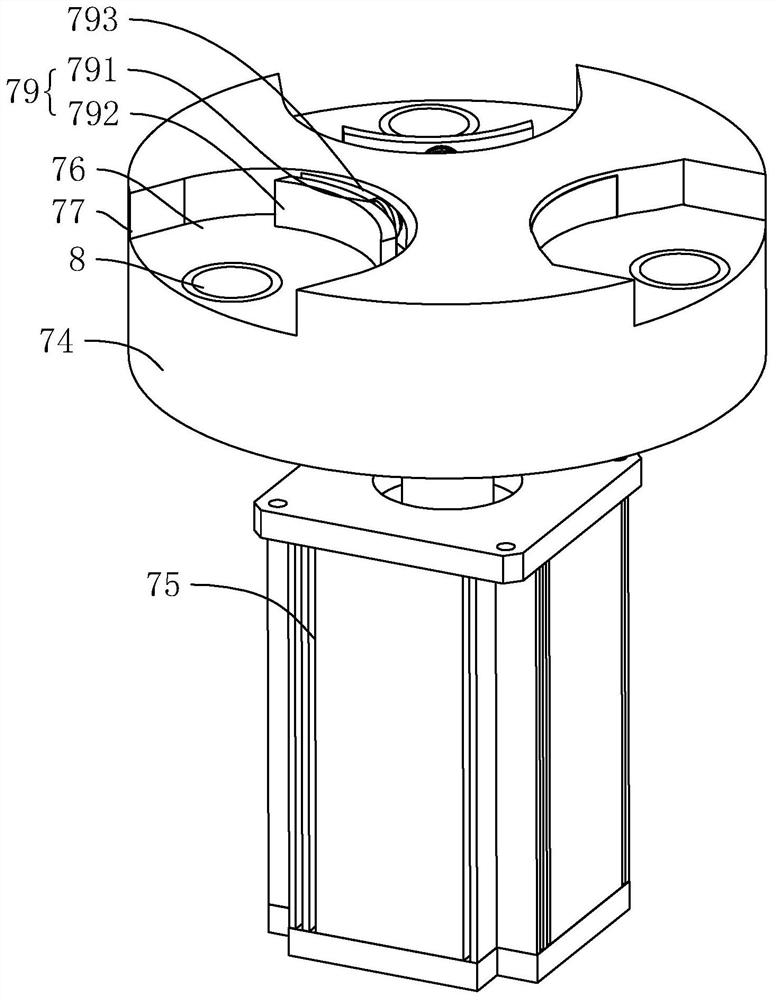

[0037] refer to figure 1 , a kind of automobile stator and rotor punching and deburring device, including a base 1, a transmission device, a deburring device 7 for grinding the top surface of the stator and rotor punching, and a burr grinding device 7 for grinding the stator and rotor punching The turning device 6 of turning over, the transmission device comprises transmission belt one 2, transmission belt two 3, transmission belt three 4, transmission belt four 5, transmission belt one 2, transmission belt two 3, transmission belt three 4, transmission belt four 5 Both are driven by the transmission motor 11 fixed on the base 1 through the pulley, the transmission belt 1 2, the transmission belt 2 3, the transmission belt 3 4, and the transmission belt 4 5 are arranged in sequence along the transmission direction of the stator and rotor punching, and the burr gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com