Cam jacking poly V-belt transfer machine

A V-ribbed belt and transfer machine technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of overall system efficiency impact, time-consuming, unusable, etc., to improve sorting efficiency, The effect of reducing processing cost and reducing processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

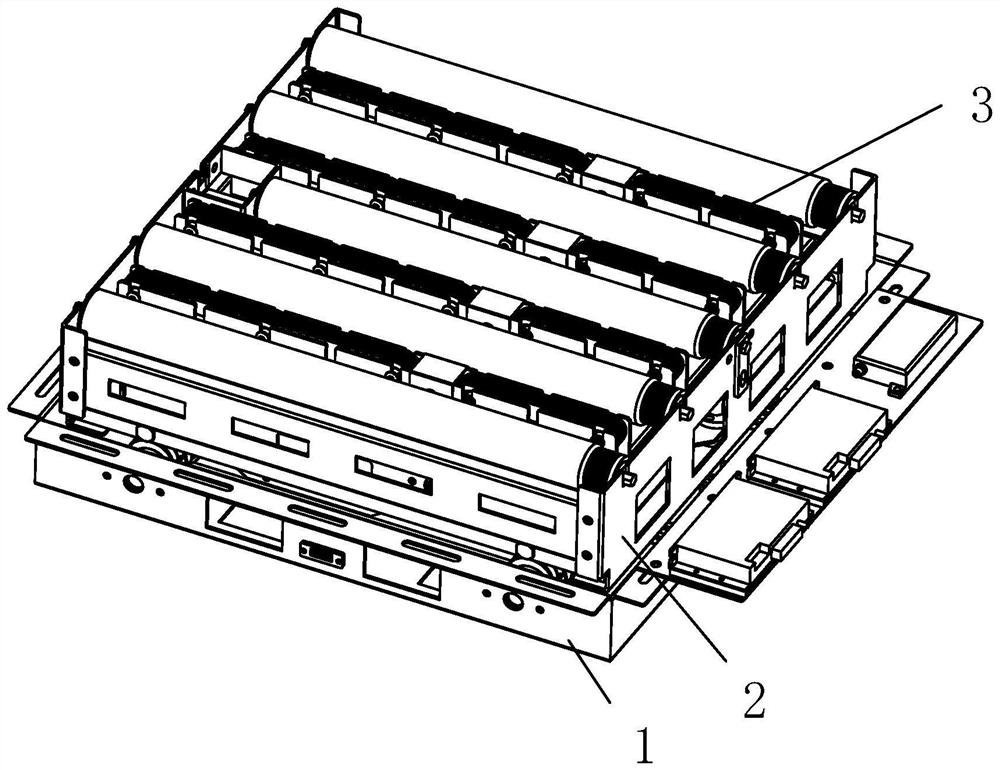

[0042] like Figure 1 to Figure 7 As shown in the figure, a cam-lifting V-belt transfer machine can realize high-speed transfer and transportation, and it runs smoothly and reliably, and has a large bearing capacity. The conveying mechanism 3 is arranged on the cam lifting mechanism 1, and the V-ribbed belt conveying mechanism 3 is embedded in the roller conveying mechanism 2 so that they are distributed at intervals. Driven by the cam lifting mechanism 1, the roller conveys The mechanism 2 and the V-belt conveying mechanism 3 are alternately lifted and arranged.

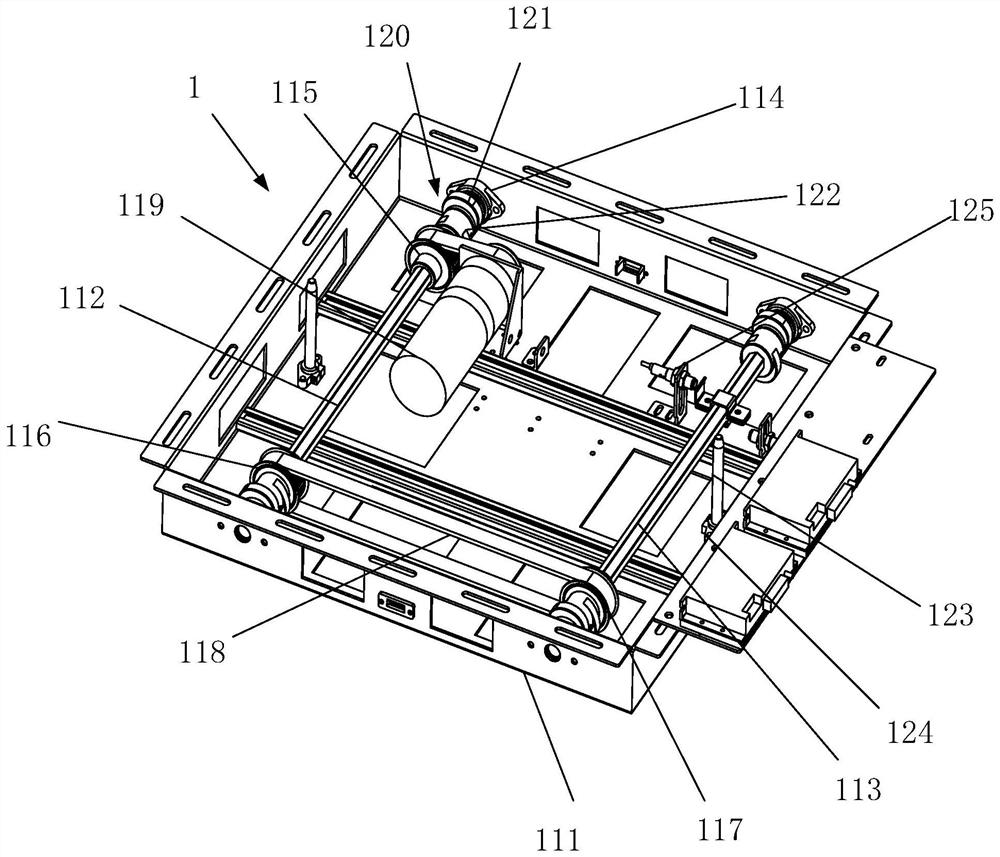

[0043] like figure 2 As shown, the cam lifting mechanism 1 in the present invention includes a cam base 111, and a first camshaft 112 and a second camshaft 113 are arranged in the cam base 111, which are spaced apart and arranged in parallel, and the first camshaft One end of 112 is provided with driving synchronous pulley 115, and its other end is provided with synchronous pulley 116, and described second camsha...

Embodiment 1

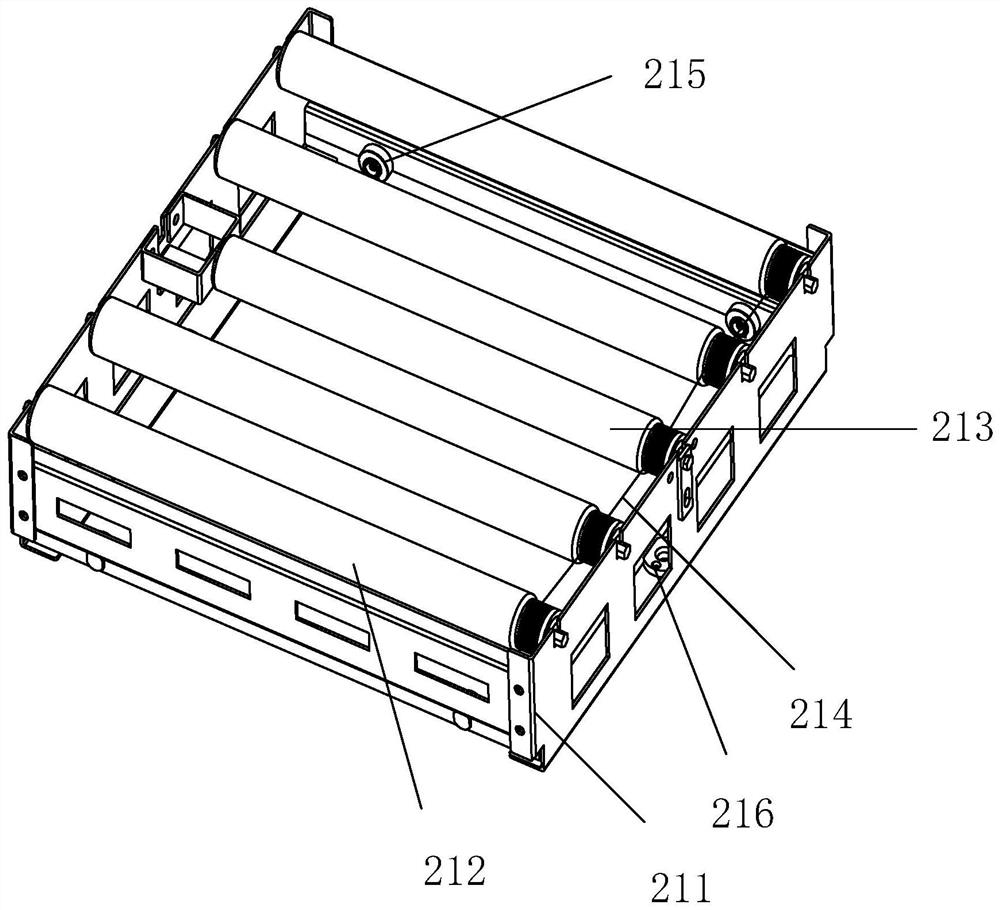

[0053] On the basis of the above-mentioned embodiments, the present invention further defines each mechanism for lifting the respective mechanisms. In the present invention, the cam base 111 is provided with a lifting guide rod 123 through a guide rod support 124. The lifting The guide rod 123 is positioned at the side of the first camshaft 112 and the second camshaft 113, and the height of the lifting guide rod 123 is higher than the plane height of the cam base 111; Block 216, the first lifting guide post guide block 216 is opposite to the lifting guide rod 123, and the first lifting guide post guide block 216 is connected on the lifting guide rod 123; the wedge belt frame 311 is provided with a second Two lifting guide column guide blocks 314, the second lifting guide column guide block 314 is opposite to the lifting guide rod 123, and the second lifting guide column guide block 314 is connected on the lifting guide rod 123, and the second lifting guide column guide block 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com