Ultra-sensitive micro-vibration detection device

A detection device and micro-vibration technology, which is applied to measurement devices, uses electrical devices, measures ultrasonic/sonic/infrasonic waves, etc., can solve the problems of inability to monitor the weak vibration of low-temperature devices with high sensitivity and low sensitivity, and achieve high vibration detection sensitivity. , the effect of changing the magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

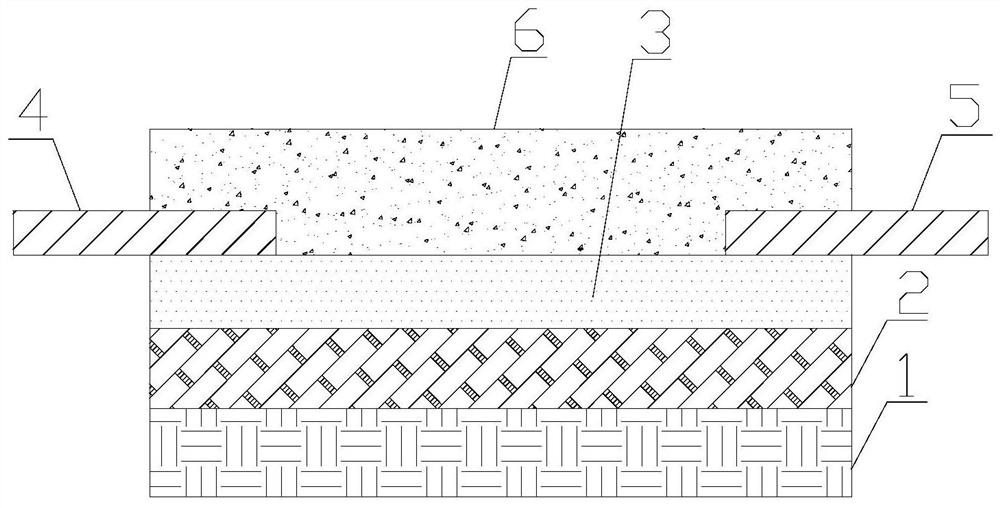

[0020] The invention provides an ultra-sensitive micro-vibration detection device, such as figure 1 As shown, it includes an antiferromagnetic layer 1 , a pinning layer 2 , a barrier layer 3 , a first elastic part 4 , a second elastic part 5 , and a free layer 6 . The material of the antiferromagnetic layer 1 is a hard magnetic antiferromagnetic material, specifically, the material of the antiferromagnetic layer 1 is IrMn, PtMn, FeMn. The pinning layer 2 is placed on the antiferromagnetic layer 1 . The material of the pinning layer 2 is a metal or semi-metal with high spin polarizability, specifically, the material of the pinning layer 2 is Co, Fe, CoFe, CoFeB, CoFeAl alloy. The barrier layer 3 is placed on the pinning layer 2 . The material of the barrier layer 3 is aluminum oxide or magnesium oxide. The first elastic part 4 and the second elastic part 5 are respectively fixed on two sides of the barrier layer 3 . The first elastic part 4 and the second elastic part 5 ext...

Embodiment 2

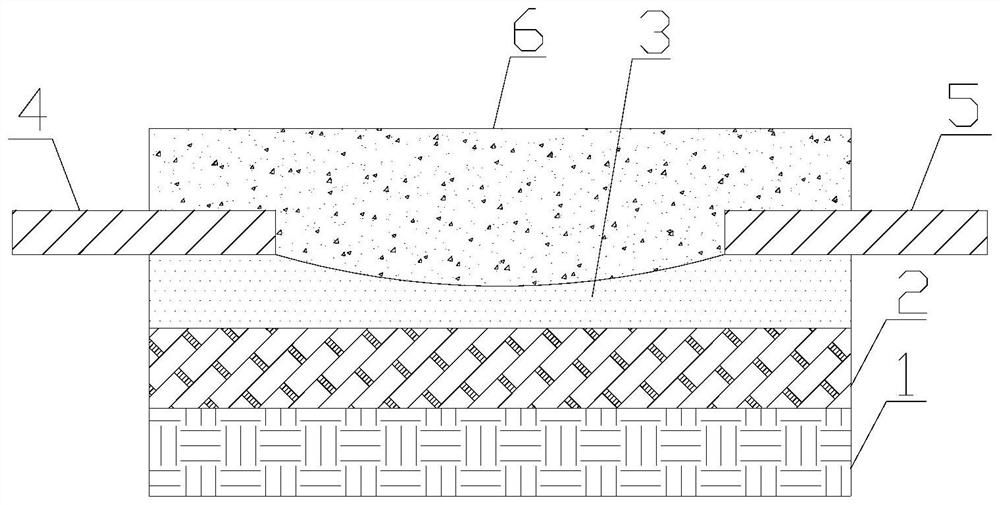

[0025] On the basis of Example 1, such as figure 2 As shown, the surface of the barrier layer 3 is provided with a concave shape. The concave shape is placed in the middle of the surface of the barrier layer 3 , and the first elastic part 4 and the second elastic part 5 are symmetrically arranged on the barrier layer 3 . In this way, on the one hand, the thickness of the middle part of the barrier layer 3 is smaller, and it is easier for electrons to tunnel from the middle part of the barrier layer 3; Under the action of the elastic part 5, the stress in the barrier layer 3 changes relatively more, thereby changing the quantum tunneling characteristics of the barrier layer 3 more, thereby changing the magnetoresistance of the magnetic tunnel junction more, thereby achieving a higher Sensitive micro-vibration detection.

Embodiment 3

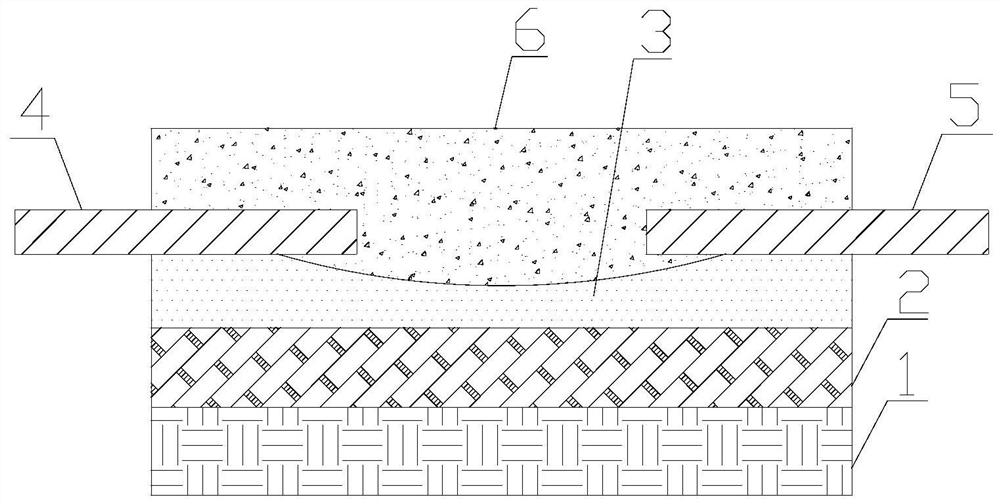

[0027] On the basis of Example 2, such as image 3 As shown, in the free layer 6 the first elastic portion 4 and the second elastic portion 5 extend to the concave upper side. That is to say, the material of the free layer 6 is provided between the first elastic part 4 and the concave surface of the barrier layer 3 , and between the second elastic part 5 and the concave surface of the barrier layer 3 . In this way, when the first elastic part 4 and the second elastic part 5 vibrate, not only the stress in the barrier layer 3 is changed, but also the stress between the first elastic part 4 and the concave surface of the barrier layer 3 is changed. The interface between the free layer 6 material between the second elastic portion 4 and the concave surface of the barrier layer 3 and the concave surface of the barrier layer 3, thereby changing the quantum tunneling characteristics of the interface, thereby changing more The magnetoresistance of the magnetic tunnel junction enable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com