Novel indirect air cooling method and device

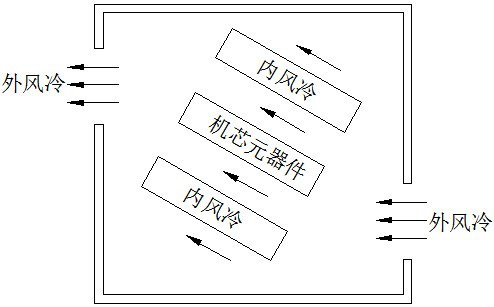

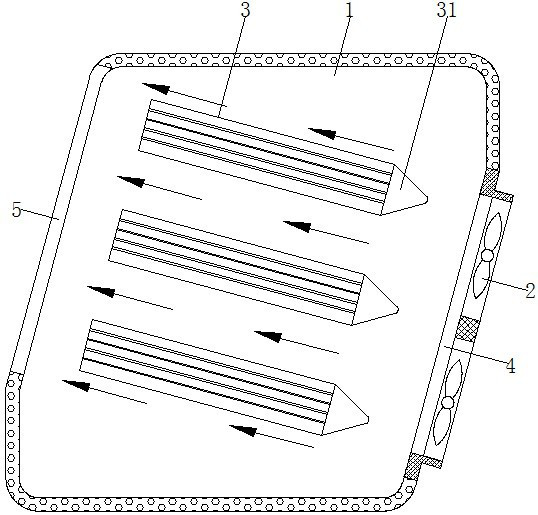

An air-cooling device and air-cooling technology, applied in the direction of instruments, electrical digital data processing, and digital data processing components, etc., can solve problems such as dust short circuit, increased dust volume of servers, and affecting reliability, so as to improve heat absorption and improve Sealed heat dissipation effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

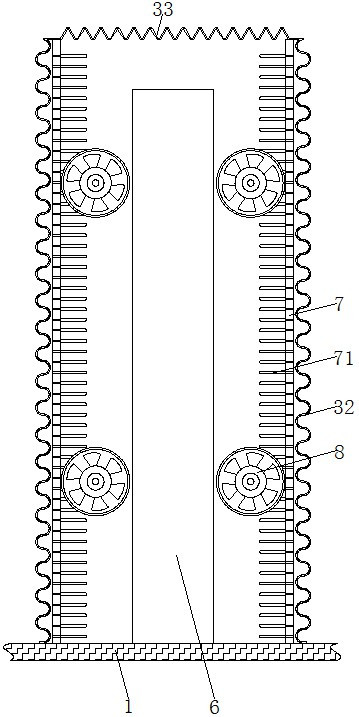

[0041] The "dust-free server" is manufactured with indirect air-cooling technology. The server core configuration: 8-core CPU, 16G memory, 2T hard disk, and a total power of 300W are the same as the air-cooled server core configuration.

[0042] The server case is changed to a sealed case, and various interfaces are retained. The sealing degree is in accordance with the IP54 standard, that is, dustproof of level 5 and waterproof of level 4. The chassis material is 1.5mm iron plate, with heat-absorbing inner coating and heat-dissipating outer coating, the surface heat dissipation coefficient is close to 30W / (m²℃), the chassis specification is 2U, and the total area of the chassis is 0.73 square meters. Fans are used outside the chassis to dissipate heat, and the wind speed on the upper and lower surfaces of the server is maintained at 2.5 m / s.

[0043]Third-party test results: When the CPU is running at 99% power, the ambient temperature is 36°C, and the air temperature insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com